Concrete additive

A concrete and additive technology, applied in the field of concrete additives, can solve problems such as single performance and poor protection effect, and achieve the effects of improving compression resistance, preventing rust, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

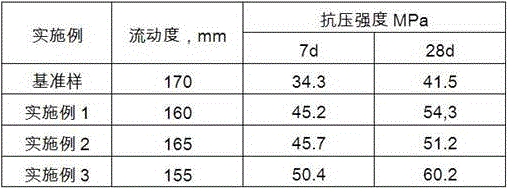

Examples

Embodiment 1

[0021] Embodiment 1 of the present invention provides a kind of concrete additive, is made up of the following components by weight: 15 parts of modified cement, 10 parts of gypsum, 5 parts of carbon black, 10 parts of bentonite, 1 part of silicon dioxide, 10 parts of polypropylene fiber 1 part, 1 part of superplasticizer, 2 parts of calcium lignosulfonate, 0.3 part of sodium cetyl sulfonate, 1 part of dispersible latex powder, 0.2 part of stabilizer, 1 part of rust inhibitor, 0.5 part of waterproofing agent, Acrylic emulsion 5 parts, deionized water 10 parts.

[0022] Modified cement is mainly composed of fly ash and limestone.

[0023] The bentonite is a modified bentonite, and the modified bentonite is a calcium-based organic matter modified bentonite.

[0024] Silicon dioxide is nano silicon dioxide.

[0025] High-efficiency water reducer is polycarboxylate water reducer.

[0026] The waterproofing agent is a mixture of octyltriethoxysilane and polymethyltriethoxysilane...

Embodiment 2

[0033] Embodiment 2 of the present invention provides a kind of concrete additive, is made up of the composition of following parts by weight: modified cement 25 parts, gypsum 15 parts, carbon black 10 parts, bentonite 20 parts, silicon dioxide 3 parts, polypropylene fiber 25 parts 5 parts, 5 parts of superplasticizer, 4 parts of calcium lignosulfonate, 0.7 parts of sodium cetyl sulfonate, 9 parts of dispersible latex powder, 0.6 parts of stabilizer, 7 parts of rust inhibitor, 5 parts of waterproofing agent, Acrylic emulsion 15 parts, deionized water 25 parts.

[0034] Modified cement is mainly composed of silicate and limestone.

[0035] The bentonite is a modified bentonite, and the modified bentonite is a calcium-based organic matter modified bentonite.

[0036] Silicon dioxide is nano silicon dioxide.

[0037] High-efficiency water reducer is polycarboxylate water reducer.

[0038] The waterproofing agent is a mixture of octyltriethoxysilane and polymethyltriethoxysilan...

Embodiment 3

[0045] Embodiment 3 of the present invention provides a concrete additive, which is composed of the following components by weight: 20 parts of modified cement, 12 parts of gypsum, 7.5 parts of carbon black, 15 parts of bentonite, 2 parts of silicon dioxide, and 17 parts of polypropylene fiber 3 parts, 3 parts of superplasticizer, 3 parts of calcium lignosulfonate, 0.5 parts of sodium cetyl sulfonate, 5 parts of dispersible latex powder, 0.4 parts of stabilizer, 4 parts of rust inhibitor, 2.7 parts of waterproofing agent, Acrylic emulsion 10 parts, deionized water 17 parts.

[0046] Modified cement is mainly composed of fly ash, limestone and bauxite.

[0047] The bentonite is a modified bentonite, and the modified bentonite is a calcium-based organic matter modified bentonite.

[0048] Silicon dioxide is nano silicon dioxide.

[0049] High-efficiency water reducer is polycarboxylate water reducer.

[0050] The waterproofing agent is a mixture of octyltriethoxysilane and po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com