Production method of rolled thick-specification composite steel plate

A clad steel plate and production method technology, applied in the production of rolled clad plate with a thickness ≥ 50mm, and in the production field of rolled thick clad plate, can solve the problems such as difficulty in producing thick clad plate, and achieve a good and wide lamination effect The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

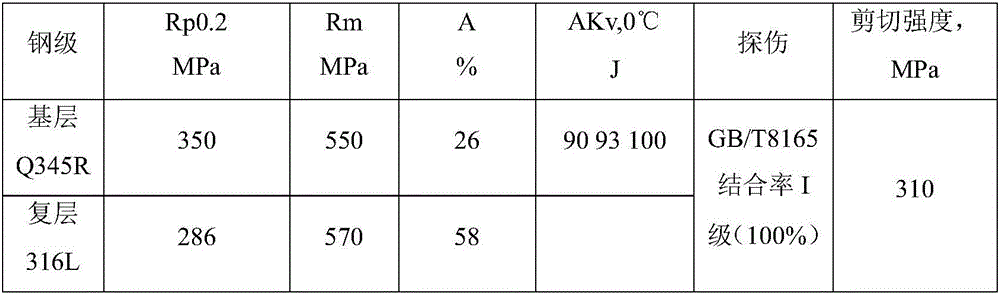

[0020] In this embodiment, Q345R is selected as the base layer material, and 316L is selected as the compound layer material. The specifications of the finished composite board are: (47+3)+(27+3) thickness×2040 width×12000 length mm, of which the thickness of Q345R is 47 and 27mm respectively, and the thickness of stainless steel is 3mm.

[0021] The production process includes billet assembly, heating, rolling, and water cooling, specifically:

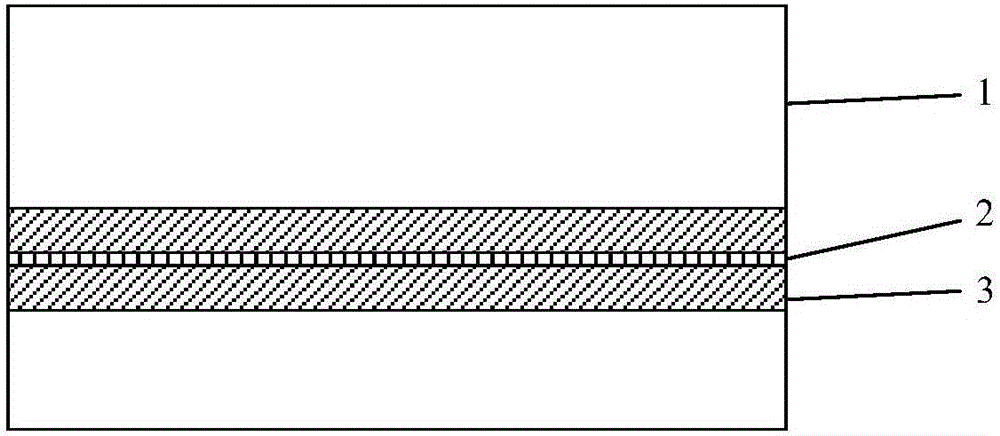

[0022] (1) The steel billets designed and smelted according to the chemical composition are subjected to billet rolling; the thickness of the carbon steel Q345R billet is 247 and 142 mm respectively, and the thickness of the stainless steel intermediate billet is 16 mm. The surface cleaning of the composite surface is carried out by using a milling machine or an abrasive belt grinder. then follow figure 1 Combining the examples, adding a release agent between the stainless steels, and then welding and sealing the billet on four sides...

Embodiment 2

[0028] In this embodiment, A533B Class I is selected as the material of the base layer, and 304L is selected as the material of the multilayer. The finished product specifications of the composite board are: (62+7)+25 thickness×2040 width×12000 length mm, among which the thickness of A533B is 62 and 25mm respectively, and the thickness of stainless steel is 7mm.

[0029] The production process includes billet assembly, heating, rolling, and heat treatment, specifically:

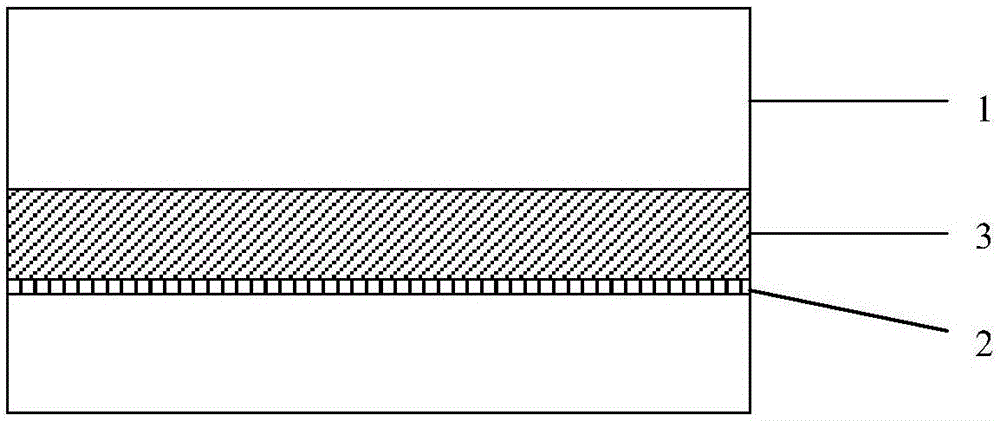

[0030] (1) The steel billets designed and smelted according to the chemical composition are subjected to billet rolling; the carbon steel A533B billets have a thickness of 277 and 112mm, and the stainless steel intermediate billet has a thickness of 32mm. The surface of the composite surface is cleaned by a milling machine or an abrasive belt grinder. then follow figure 2 Example combination, stainless steel and thin-gauge carbon steel 112mm steel billet is added with a release agent, and the billet is then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com