Hexagonal nickel/cobalt oxide oxygen evolution catalyst, and preparation method and application thereof

A technology of cobalt oxide and catalyst, which is applied in the field of hexagonal nickel/cobalt oxide oxygen evolution catalyst and its preparation and application, can solve the problem of low activity and achieve high oxygen evolution catalytic activity and good oxygen evolution electrocatalytic performance , the effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] preparation:

[0041] (1) Mixing of precursor solution: First, weigh 0.7 mmol of nickel sulfate and 0.3 mmol of cobalt sulfate and dissolve them in a mixed solvent of 30 mL of water / ethanol (v / v=20:10), stir for 10 minutes, add 2 mL of oleylamine, and vigorously Stir for 20min.

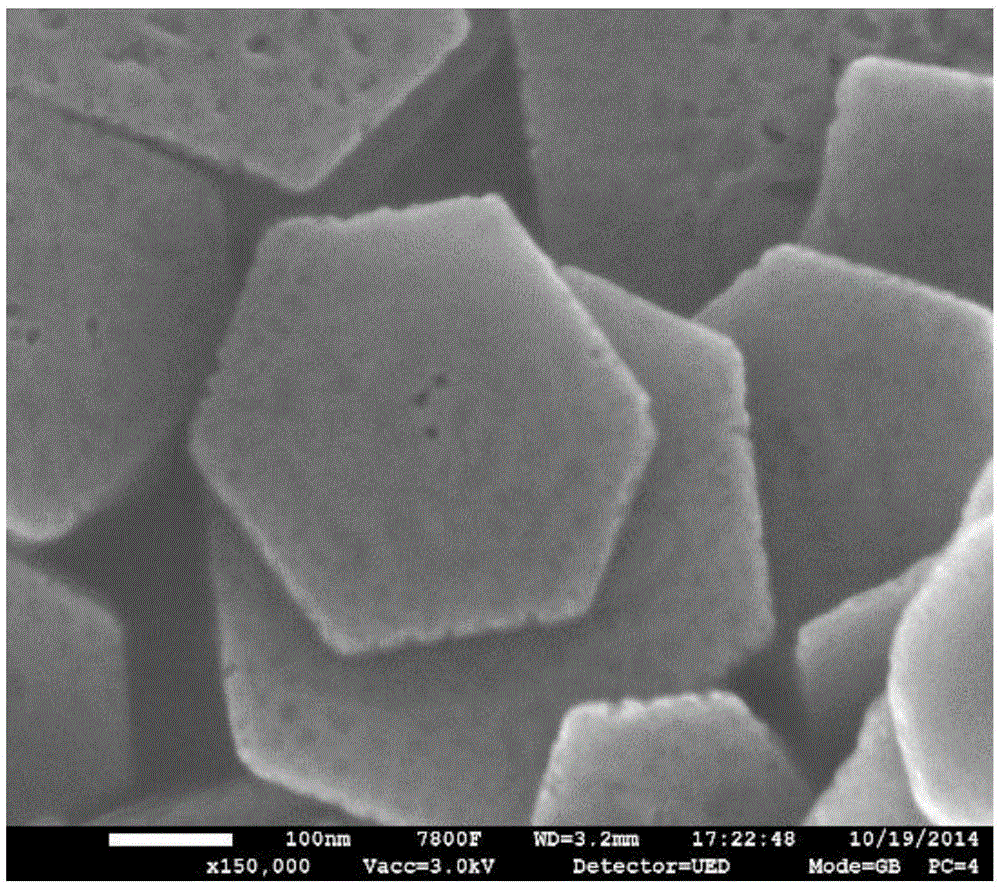

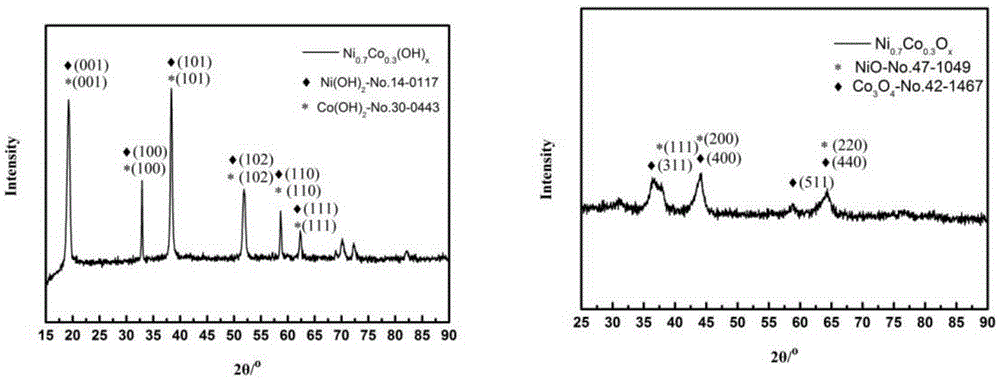

[0042](2) Hydrothermal reaction: Transfer the mixed solution obtained in (1) to a 50mL hydrothermal kettle, set the reaction temperature in a blast drying oven to 180°C, and perform hydrothermal reaction for 15 hours to obtain hydroxide, centrifuge Wash 3 to 5 times and dry in vacuum for 8 hours.

[0043] (3) Roasting: the dried sample was moved to a tube furnace and heated at 400° C. for 2 hours to obtain nickel-cobalt oxide.

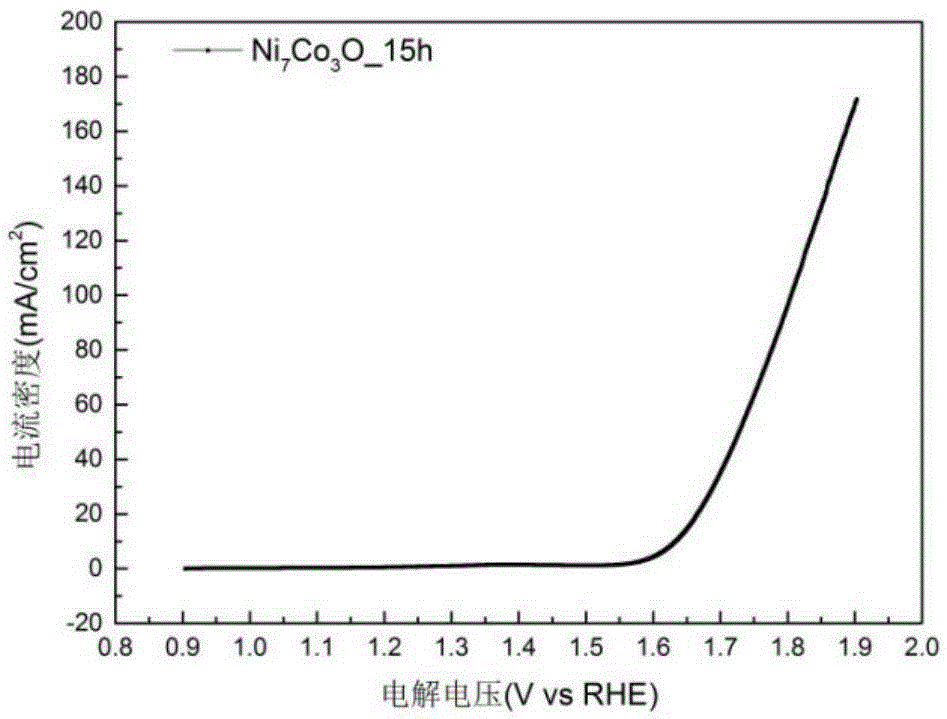

[0044] Half-cell test: The half-cell system uses 1M KOH solution as the electrolyte, Ni 7 co 3 o x Electrocatalysts perform LSV sweeps, such as image 3 shown. The Ni prepared by this method 7 co 3 10mA / cm in 1M KOH electrolyte solution 2 The potential at the ...

Embodiment 2

[0046] Take the same preparation process as in Example 1, change the reaction conditions to 160°C, and conduct a hydrothermal reaction for 12 hours. The half-cell test steps used are as described in Example 1, and the relevant test results are as follows Figure 4 shown. The Ni prepared by this method 7 co 3 (OH)x 10mA / cm in 1M KOH electrolyte solution 2 The potential at the electrolysis current density is 1.624V (vs.RHE).

Embodiment 3

[0048] The process as described in Example 2 was used to prepare hexagonal nickel-cobalt oxide nanosheets, and used it as an oxygen evolution electrocatalyst for an alkaline solid electrolyte water electrolysis cell. During the experiment, it was found that nickel-cobalt oxide nanosheets have good oxygen evolution catalytic activity and stability in alkaline solid electrolyte water electrolysis cells. When the mass ratio of catalyst to resin (AS-4) in the catalytic layer is 5:1 , the cathode uses 40wt.% PtC as the hydrogen evolution catalyst, and the electrolytic cell is tested for polarization curve at 50°C. The steady-state polarization curve of the full battery measured under the same test conditions as Example 2 is as follows: Figure 5 shown. 50℃, 100mA / cm 2 The electrolytic cell stability test data measured under the conditions are as follows: Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com