Method for rapidly and accurately measuring low angle grain boundary orientation under transmission electron microscope

An electron microscope and precise measurement technology, applied in the direction of material analysis using radiation diffraction, etc., can solve problems such as troublesome, cumbersome data processing, and not many, and achieve the effect of simple calculation formula, convenient calculation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

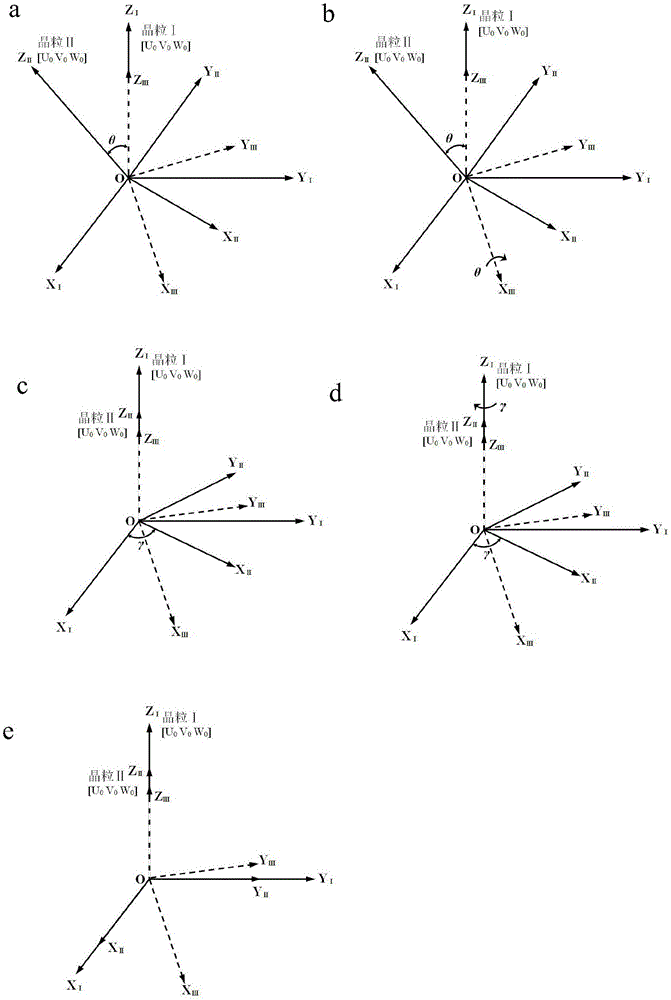

Method used

Image

Examples

Embodiment 1

[0065] The test material is a 7075 aluminum alloy thin strip with an average grain size of 1 μm. Cut out a thin strip of 3mm×5mm×0.05mm, and grind it with water sandpaper to a thickness of 30μm. The Φ3mm sample was cut and double-jet thinned to prepare a thin area.

[0066] The above-prepared sample was clamped on the electron microscope by using the double-tilt sample rod of the Jem2010 electron microscope, and the applied voltage was 200KV. Find the two grains to be detected in the sample.

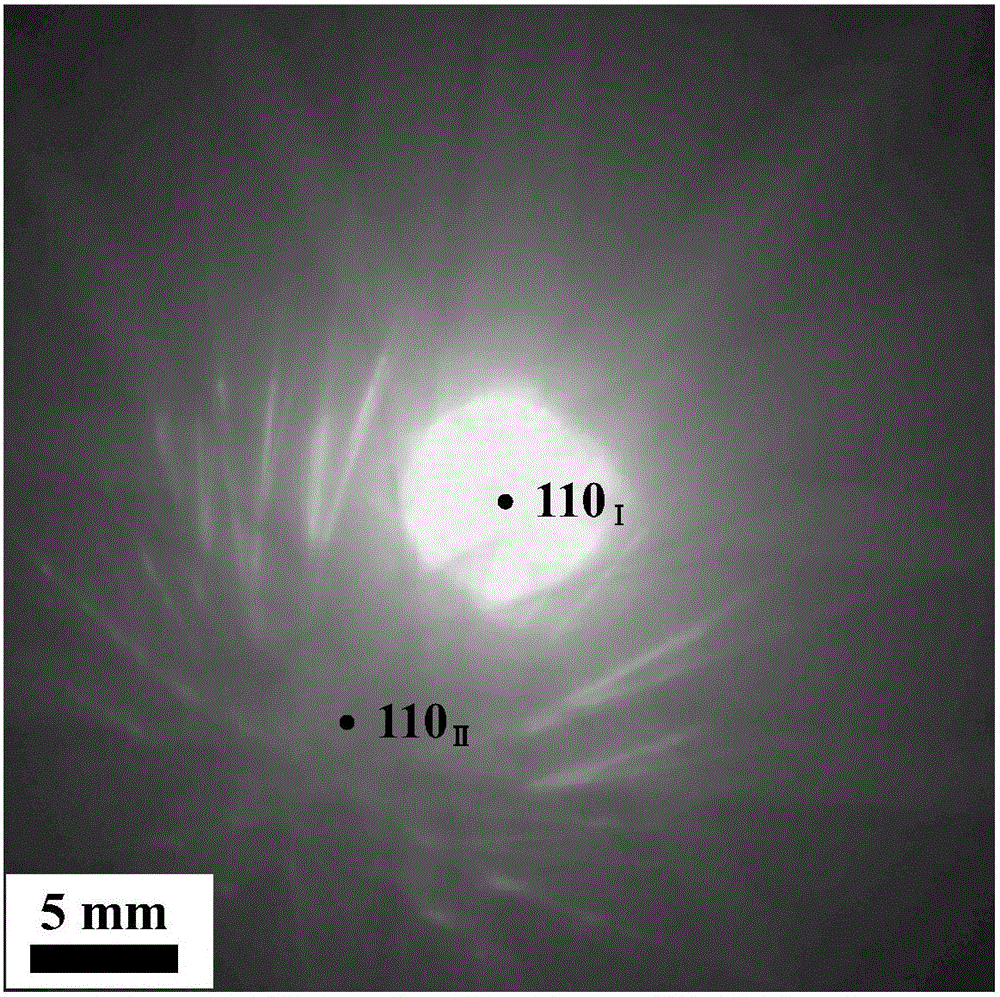

[0067] Step 1: Tilt the grain coordinate system Ⅰ (hereinafter referred to as grain Ⅰ) to the low-index zone axis by using the double-tilt technique. Since the grain is relatively close to the [110] zone axis, the grain Ⅰ is tilted to [110] Zonal axis. When the camera constant is adjusted to 250mm, the grain I Kikuchi line is photographed.

[0068] Step 2: keep the camera constant, and collect the Kikuchi line of grain coordinate system II (hereinafter referred to as grain II).

[0...

Embodiment 2

[0074] The detection material is hot-pressed sintered 5083Al, with an average grain size of 200nm. Cut out a thin slice of 3 mm×5 mm×0.5 mm, and grind it with water sandpaper to a thickness of 30 μm. The Φ3mm sample was cut and double-jet thinned to prepare a thin area.

[0075] The above-prepared sample was clamped on the electron microscope by using the double-tilt sample rod of the Jem2010 electron microscope, and the applied voltage was 200KV. Find the two grains to be detected in the sample.

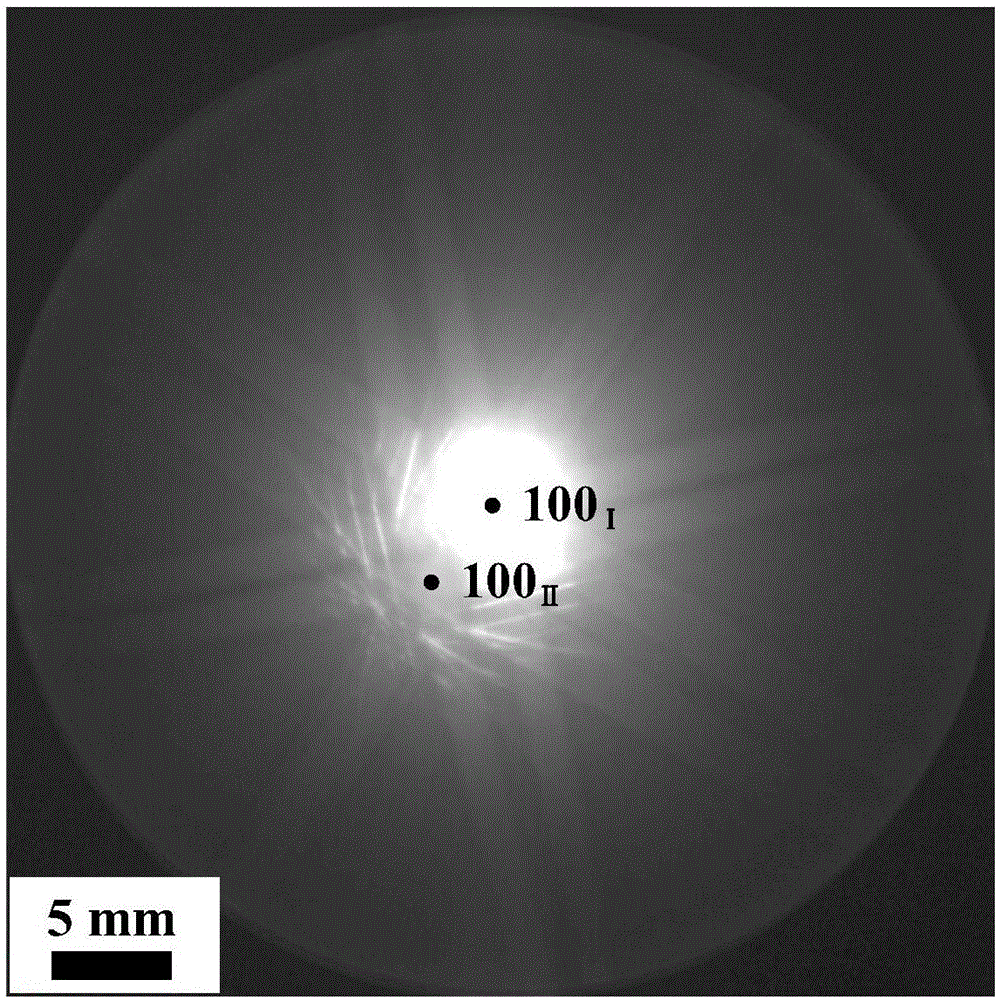

[0076] Step 1: Tilt the crystal grain I to the low-index zone axis by using the double-tilt technique. Since the grain is relatively close to the [001] zone axis, tilt the crystal grain I to the [001] zone axis. When the camera constant is adjusted to 250mm, the grain I Kikuchi line is photographed.

[0077] Step 2: keep the camera constant, and collect the Kikuchi line of grain II.

[0078] Step 3: Use Gatan DigitalMicrograph software to superimpose the collected Kikuchi line o...

Embodiment 3

[0083] The detection material is hot-pressed sintered 5083Al, with an average grain size of 100nm. Cut out a thin slice of 3 mm×5 mm×0.5 mm, and grind it with water sandpaper to a thickness of 30 μm. The Φ3mm sample was cut and double-jet thinned to prepare a thin area.

[0084] The above-prepared sample was clamped on the electron microscope by using the double-tilt sample rod of the Jem2010 electron microscope, and the applied voltage was 200KV. Find the two grains to be detected in the sample.

[0085] Step 1: Direct observation finds that grain I is near the low-index zone axis [110], and when the camera constant is adjusted to 250mm, directly photograph the Kikuchi line of grain I.

[0086] Step 2: keep the camera constant, and collect the Kikuchi line of grain II.

[0087] Step 3: Use Gatan DigitalMicrograph software to superimpose the collected Kikuchi line of grain Ⅰ and Kikuchi line of grain Ⅱ, and pay attention to keep the coincidence of the transmission spots, su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com