Supercritical CO2 waterless boiling-off device and boiling-off method for flax roving

A supercritical and scouring technology, applied in the direction of sustainable manufacturing/processing, textile/flexible product manufacturing, equipment configuration for processing textile materials, etc., can solve problems such as high pollution and high energy consumption, and achieve the effect of increasing the separation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The structure of the scouring kettle used in the following examples is the supercritical carbon dioxide cheese dyeing kettle in the Chinese patent whose publication number is CN102787459A, such as the dyeing kettle structure described in Example 1 in the publication.

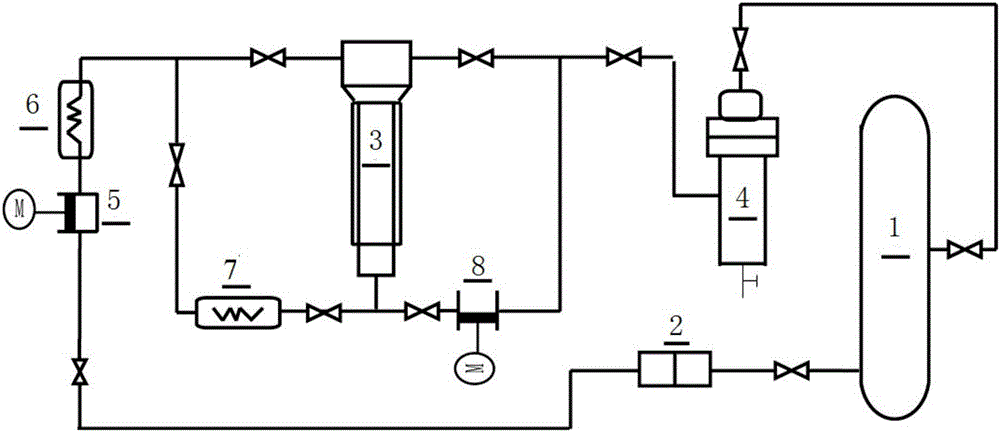

[0037] A kind of flax roving supercritical CO of the present invention 2 Cooking device:

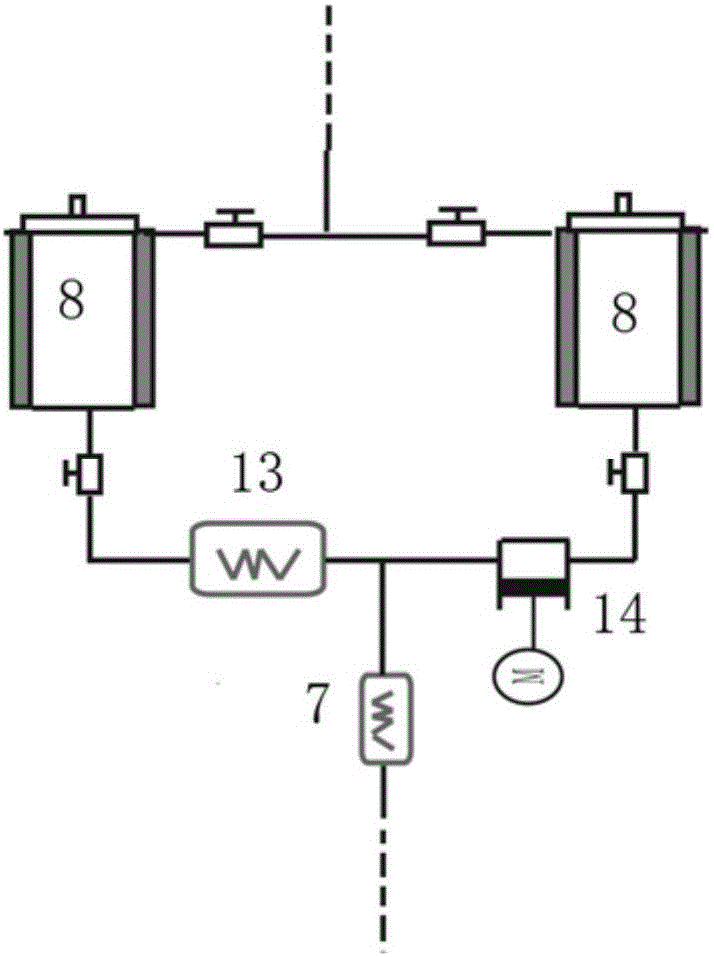

[0038] A flax roving supercritical CO 2 Anhydrous scouring device, including structural unit CO 2 storage tank 1, filter 2, booster pump 5, preheater 6, heater 7, scouring kettle 3, separation kettle 4 and magnetic circulation pump 8, wherein the CO 2 The storage tank 1, the filter 2, the booster pump 5, the preheater 6, the scouring kettle 3, and the separation kettle 4 are connected in sequence through pipelines, and the heater 7 is communicated with the upstream and downstream of the s...

Embodiment 2

[0051] The 5kg flax roving bobbins are sequentially connected and sleeved in the scouring kettle 8 .

[0052] During the scouring process, the refrigeration system is first turned on, and the liquid CO 2 in CO 2 The outflow from the storage tank 1 is filtered through the filter 2 to remove possible impurities, and then injected into the scouring equipment under the action of the booster pump 5; and then enters the supercritical state under the action of the preheater. From the bottom up to the flax cheese on it, it permeates and diffuses and then flows out; turn off the booster pump 5, swell the flax fiber statically at 35°C and 10MPa for 5 minutes, and perform the supercritical fluid swelling process of the flax roving. then CO 2 The fluid flows out of the scouring kettle; under the action of the magnetic circulation pump 8, the CO 2 The fluid enters the scouring kettle 3 again, raises the temperature to 80°C and the pressure to 15MPa, and circulates and scours the flax fi...

Embodiment 3

[0056] The 10kg flax roving bobbins are sequentially connected and set in the scouring kettle 8 .

[0057] During the scouring process, the refrigeration system is first turned on, and the liquid CO 2 in CO 2The outflow from the storage tank 1 is filtered through the filter 2 to remove possible impurities, and then injected into the interior of the scouring equipment under the action of the booster pump; and then enters the supercritical state under the action of the preheater. From the bottom up to the flax cheese on it, it permeates and diffuses and then flows out; turn off the booster pump 5, and swell the flax fiber under static conditions at 70°C and 12MPa for 10 minutes to perform the supercritical fluid swelling process of the flax roving. then CO 2 The fluid flows out of the scouring kettle; under the action of the magnetic circulation pump, the CO 2 The fluid enters the scouring kettle again, raises the temperature to 100°C and the pressure to 20MPa, and circulates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com