Foaming injection material for automobile steering wheels and preparation method thereof

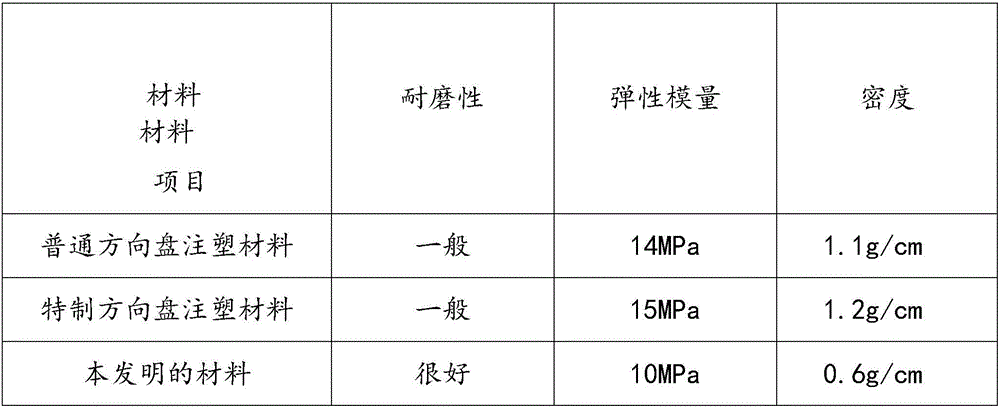

A steering wheel and automobile technology, applied in the field of foam injection molding materials and their preparation, can solve the problems of poor wear resistance, poor steering wheel elasticity, and inability to resist aging, and achieve good wear resistance, low density, and good elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A foam injection molding material for an automobile steering wheel, made of the following materials in parts by weight, including 55 parts of polyurethane, 19 parts of ethylene-vinyl acetate copolymer, 8 parts of polypropylene, 22 parts of aromatic polycarbonate, carbonic acid 16 parts of sodium, 35 parts of dichlorodifluoromethane, 6 parts of sodium lauryl sulfate, 11 parts of isocyanate, 23 parts of sodium ricinoleate, 17 parts of polyether polyol, 8 parts of sorbitol, 7 parts of mica powder, 23 parts of sodium pyrophosphate, 6 parts of ammonium polyphosphate, 11 parts of stearic acid, 13 parts of polyethylene polyamine, 2 parts of butadiene and 8 parts of silicon dioxide.

[0020] A kind of preparation method of the foam injection molding material of automobile steering wheel, comprises the following steps:

[0021] 1) 55 parts of polyurethane, 19 parts of ethylene-vinyl acetate copolymer, 8 parts of polypropylene, 22 parts of aromatic polycarbonate, 16 parts of sodi...

Embodiment 2

[0028] A foam injection molding material for an automobile steering wheel, made of the following materials in parts by weight, including 58.5 parts of polyurethane, 21.5 parts of ethylene-vinyl acetate copolymer, 12 parts of polypropylene, 23.5 parts of aromatic polycarbonate, carbonic acid 18 parts of sodium, 37.5 parts of dichlorodifluoromethane, 7 parts of sodium lauryl sulfate, 12.5 parts of isocyanate, 24 parts of sodium ricinoleate, 18.5 parts of polyether polyol, 9 parts of sorbitol, 9 parts of mica powder, 23.5 parts of sodium pyrophosphate, 7.5 parts of ammonium polyphosphate, 12.5 parts of stearic acid, 14.5 parts of polyethylene polyamine, 3 parts of butadiene and 9 parts of silicon dioxide.

[0029] A kind of preparation method of the foam injection molding material of automobile steering wheel, comprises the following steps:

[0030] 1) 58.5 parts of polyurethane, 21.5 parts of ethylene-vinyl acetate copolymer, 12 parts of polypropylene, 23.5 parts of aromatic pol...

Embodiment 3

[0037]A foaming injection molding material for an automobile steering wheel, made of the following materials in parts by weight, including 62 parts of polyurethane, 24 parts of ethylene-vinyl acetate copolymer, 16 parts of polypropylene, 25 parts of aromatic polycarbonate, carbonic acid 20 parts of sodium, 40 parts of dichlorodifluoromethane, 8 parts of sodium lauryl sulfate, 14 parts of isocyanate, 25 parts of sodium ricinoleate, 20 parts of polyether polyol, 10 parts of sorbitol, 11 parts of mica powder, 24 parts of sodium pyrophosphate, 9 parts of ammonium polyphosphate, 14 parts of stearic acid, 16 parts of polyethylene polyamine, 4 parts of butadiene and 10 parts of silicon dioxide.

[0038] A kind of preparation method of the foam injection molding material of automobile steering wheel, comprises the following steps:

[0039] 1) 62 parts of polyurethane, 24 parts of ethylene-vinyl acetate copolymer, 16 parts of polypropylene, 25 parts of aromatic polycarbonate, 20 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com