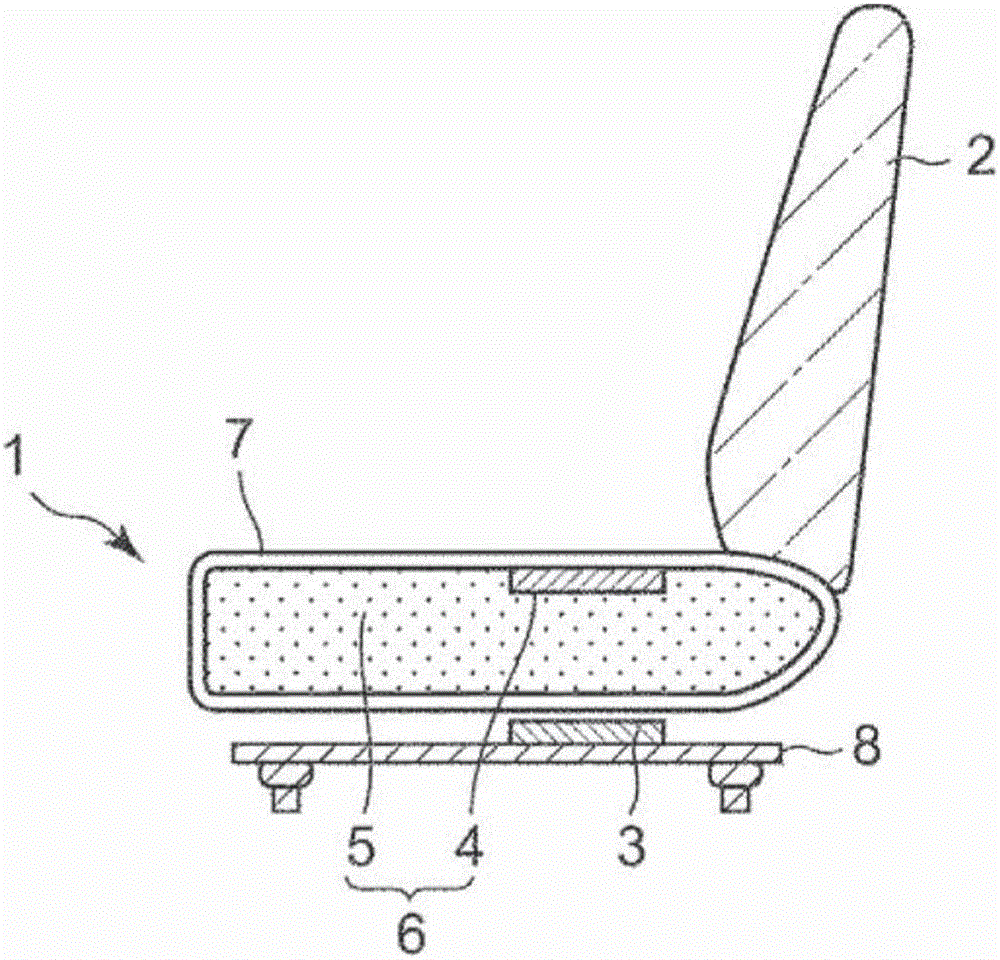

System for detecting deformation of cushion pad and process for producing same

A manufacturing method and technology of cushioning pads, which are applied in the field of deformed systems, can solve problems such as foreign body sensation, decreased detection accuracy, and difficulty in configuring the surface layer of cushioning materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0080] Manufacturing example 1 Synthesis of isocyanate-terminated prepolymer A

[0081] 42.6 parts by weight of polyol A (3-methyl-1,5-pentane adipate, OH value 56, functionality 2; manufactured by Kuraray Co., Ltd., P-2010) and 42.6 parts by weight of polyol B (polyester polyol prepared from 3-methyl-1,5-pentanediol, trimethylolpropane and adipic acid, the OH value is 56, and the functionality is 3 ; Kuraray Co., Ltd., F-3010), and dehydration under reduced pressure for 1 hour while stirring. Thereafter, the inside of the reaction container was replaced with nitrogen. Next, 14.8 parts by weight of toluene diisocyanate (manufactured by Mitsui Chemicals Co., Ltd., 2,4 configuration = 80%, Cosmonate T-80) was added to the reaction container, and the temperature in the reaction container was kept at 80° C. for 2 hours. Whereas, isocyanate-terminated prepolymer A (NCO%=3.58%) was synthesized.

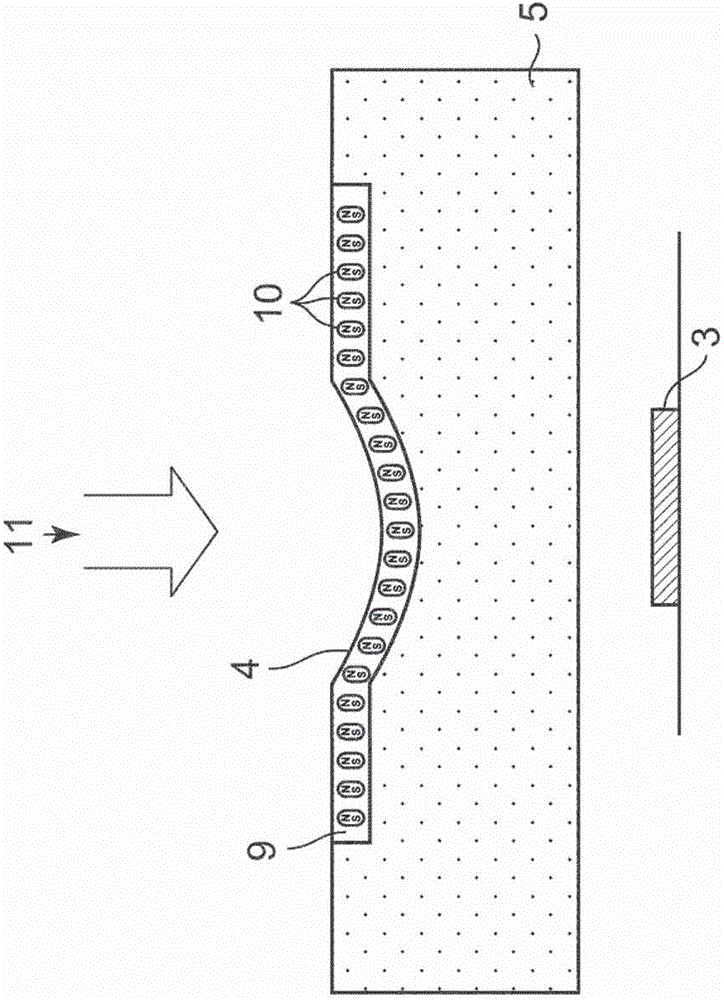

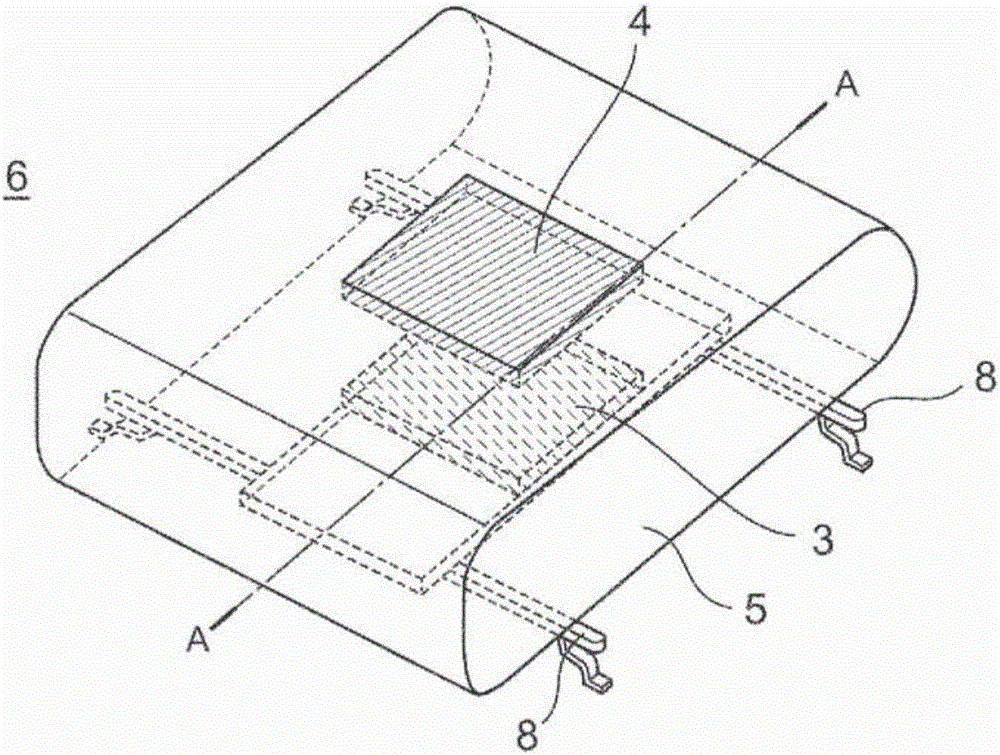

Embodiment 1

[0083] In a mixed solution of 43.8 parts by weight of polyol B, 4.8 parts by weight of silicone foam stabilizer (manufactured by Toray Dow Corning Co., Ltd., L5340) and 0.12 parts by weight of lead octoate (manufactured by Toei Chemical Co., Ltd., BTT-24) 81.0 parts by weight of a neodymium-based filler (manufactured by Aichi Steel Works Co., Ltd., MF-15P, with an average particle diameter of 33 μm) was added to prepare a filler dispersion. Air bubbles were mixed into the reaction system by vigorously stirring the filler dispersion for the first time for 5 minutes at a rotational speed of 1000 rpm using a stirring blade. Then, 51.4 parts by weight of the prepolymer A obtained above was added and stirred for the second time for 3 minutes to prepare a magnetic filler-containing urethane composition in which bubbles were dispersed. The above-mentioned bubble-dispersed urethane composition was dropped onto a release-treated polyethylene terephthalate (PET) film having a spacer of ...

Embodiment 2~9 and comparative example 1~2

[0103] The matrix layer was produced using the formulation described in Table 1, and a cushion was produced in the same manner as in Example 1, and JIS-C hardness and the like were measured to evaluate property stability. The results are shown in Table 1. In addition, Comparative Examples 1 and 2 are examples in which the base layer is not a foam, but JIS-C hardness is higher (harder) than the flexible polyurethane foam. Comparative Example 2 is an example in which the JIS-C hardness of the base layer is close to but slightly higher (harder) than the JIS-C hardness of the flexible polyurethane foam.

[0104] Example 9 is an example containing a conductive filler (silver filler). Cut the foamed resin containing conductive filler (conductive resin) obtained above into a size of 5-30 mm, and use an ion sputtering device to vapor-deposit gold on the upper and lower surfaces to prepare an electrode layer. Connect the lead wires to the electrode layer, and stick it to the buffer p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com