Heat pump heating apparatus

A heating device and heat pump technology, applied in the field of heat pump heating devices, can solve the problems of insufficient heating capacity of the heating terminal, and achieve the purpose of avoiding the temperature drop of the heated space, avoiding the feeling of insufficient heating, suppressing the suction temperature and Effect of Abnormal Increase in Suction Pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

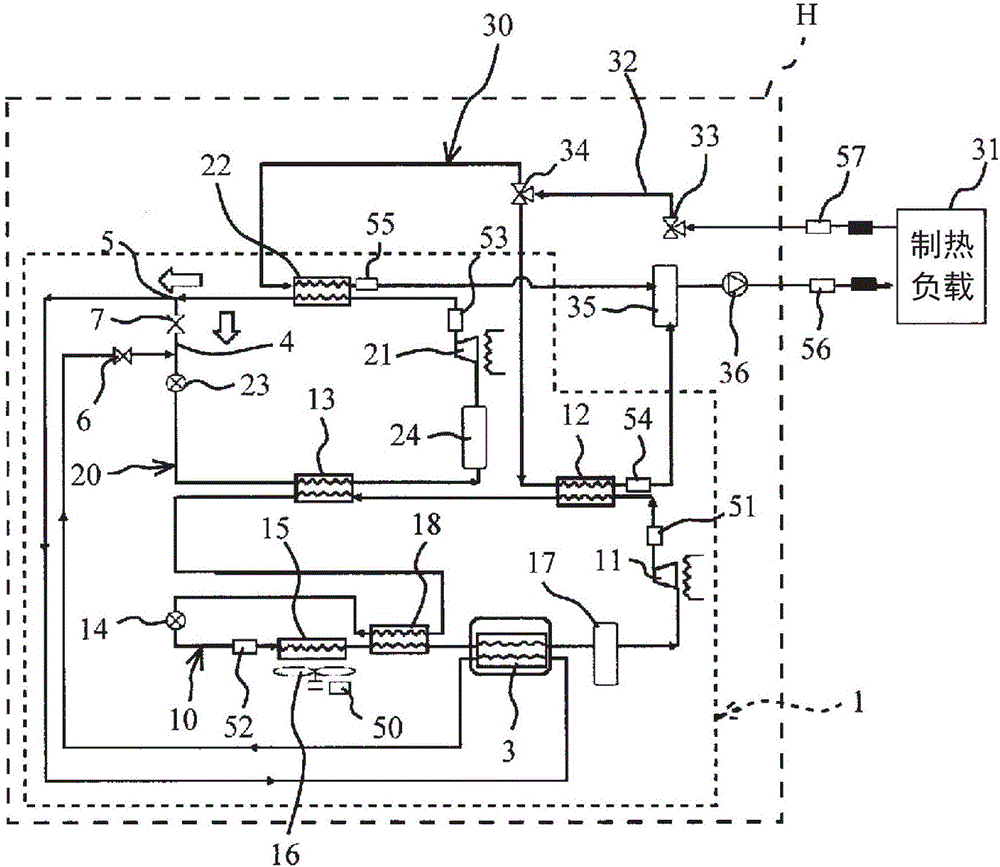

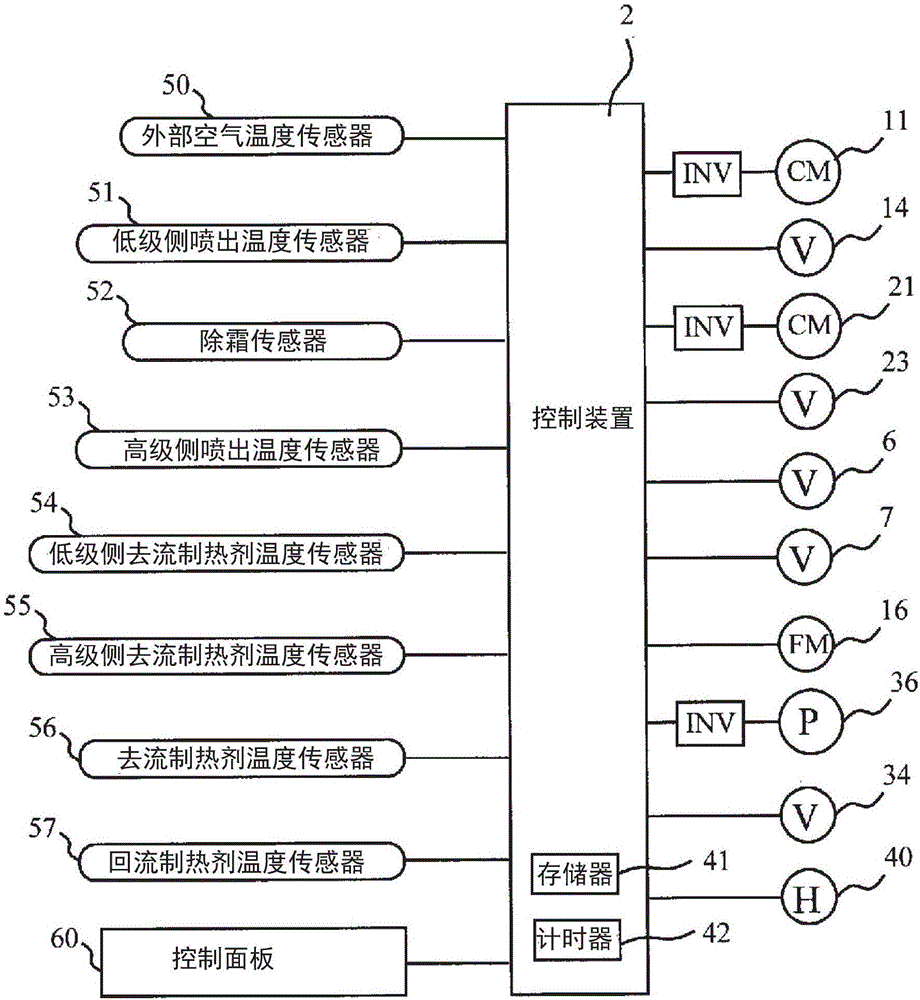

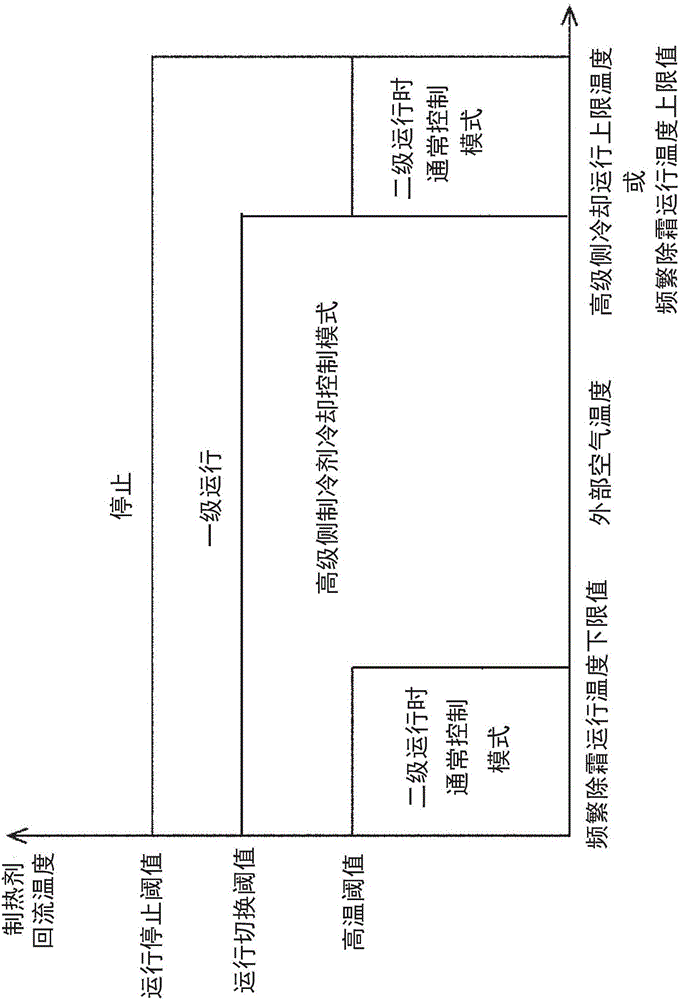

[0089] Next, an example using the heat pump heating device according to the present invention will be described. In this example, the heat pump type heating device H according to the above-mentioned present embodiment was used. In this embodiment, the operating conditions are set as follows: the outflow temperature of the refrigerant is 70°C, the external air temperature is -10°C, the operating frequency of the compressor 11 on the low-pressure side is 80 Hz, and the operating frequency of the compressor 21 on the high-pressure side is 51 Hz. The heat medium circulation flow rate is 5.6L / min in the normal control mode during the secondary operation, and 4.4L / min in the high-level side refrigerant cooling control mode (when the heat medium return temperature is 58°C). Referring to the drawings, the following discusses the case of changing the refrigerant return temperature while maintaining the normal control mode during the secondary operation, and the case of changing the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com