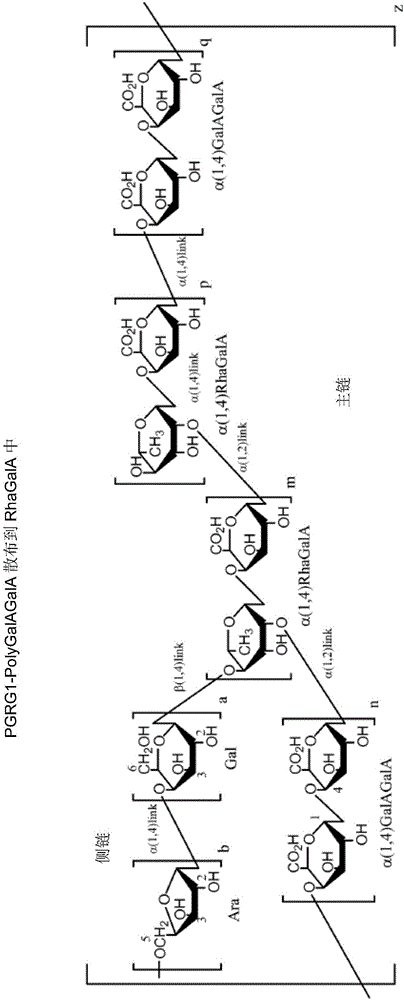

Polygalacturonan rhamnogalacturonan1 (PGRG1) composition

A technology of polygalacturonic acid and galacturonic acid, which is applied in the field of polygalacturonic acid-rhamnogalacturonic acid (PGRG1) composition, can solve the problem of huge changes in composition and potency, and changes in chemical composition , inappropriate use and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0170] Preparation of PGRG1 composition

[0171] When preparing the isolated and purified PGRG1 polysaccharide composition, hot water is first used to extract Astragalus membranaceus for preparation. Typically, treated clean root flakes or segments are obtained by trimming dry roots, cleaning with water and a disinfectant solution such as 70% ethanol, cutting into thin slices, and drying under near-sterile conditions, the output is called Slice the roots. The hot water is usually no lower than 80°C, often no lower than 90°C, and in some embodiments, about 100°C. Furthermore, a number of extraction cycles can be used for substantive and / or optimal extraction of PGRG1 from the roots, typically at least three cycles of three hours at 100°C each. The step of preparing dry root crumbs is usually carried out under near-sterile conditions using clean equipment. Concentrate the hot water extract (such as by evaporation under vacuum at 60-70°C) to bring the root slices to a concentr...

example 1

[0229] Preparation of PGRG1 composition

[0230] Step 1, root slice processing

[0231] The dried Astragalus raw material (root) (220kg) is processed into root slices by aseptic cleaning with ultrafiltered water, the contaminated part is removed, soaked overnight in 70% ethanol, cut into slices with a thickness of 0.3-0.5mm, and placed in Dry in a near-sterile oven at 60-70°C. Obtain about 200kg of dried root flakes, and the loss on drying is less than 10%.

[0232] Step 2, extraction and purification of polysaccharide composition

[0233] The dried root flakes (200 kg) were extracted 3 times with ultrafiltered water at about 100° C. for 3 hours each time. Add 2,000L of water for the first extraction, 1,600L for the second, and 1,200L for the third. A total of 4,500 L of mixed aqueous extracts was obtained and concentrated using a vacuum concentrator system at 60-80°C to obtain a concentrate with a volume of approximately 200 L. 200 L of the extract was precipitated with 70...

example 2

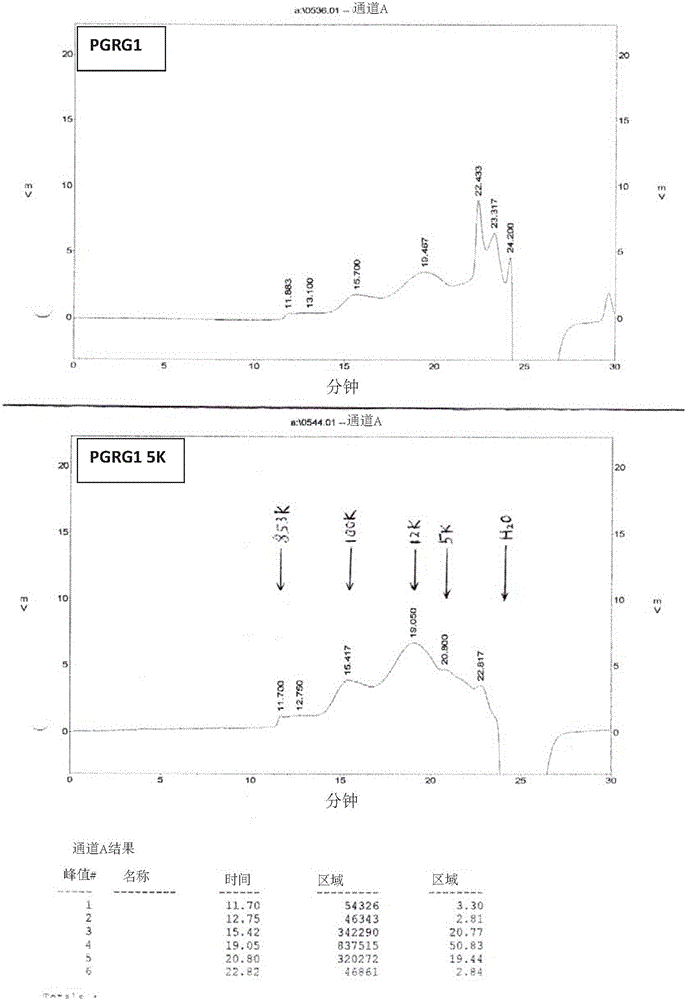

[0248] Preparation of PGRG1-5K compositions

[0249] Step 1, root slice processing (referring to example 1 step 1)

[0250] Step 2, extraction and purification of polysaccharide composition

[0251] The dried root flakes (200 kg) were extracted 3 times with ultrafiltered water at about 100° C. for 3 hours each time. Add 2,000L of water for the first extraction, 1,600L for the second, and 1,200L for the third. A total of 4,500 L of mixed aqueous extracts was obtained and concentrated using a vacuum concentrator system at 60-80°C to obtain a concentrate with a volume of approximately 200 L. 200 L of the extract was precipitated with 70% ethanol to remove small water-insoluble molecules. The resulting precipitate is then suspended in water and precipitated using 30%-35% ethanol to remove low water soluble polysaccharides, proteins and other larger molecules. The supernatant was reprecipitated in 70% ethanol to recover the highly water soluble polysaccharide or PGRG1. The pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com