High efficiency and wide-range speed control method for stator permanent magnet type memory motor

A technology of memorizing motors and control methods, which is applied in the field of electric transmission, can solve the problems of efficiency optimization and wide speed regulation closed-loop control methods that have not been reported in research reports, and achieve the effects of reducing the difference in actual loss, improving accuracy, and avoiding large calculation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further explained below in conjunction with the accompanying drawings.

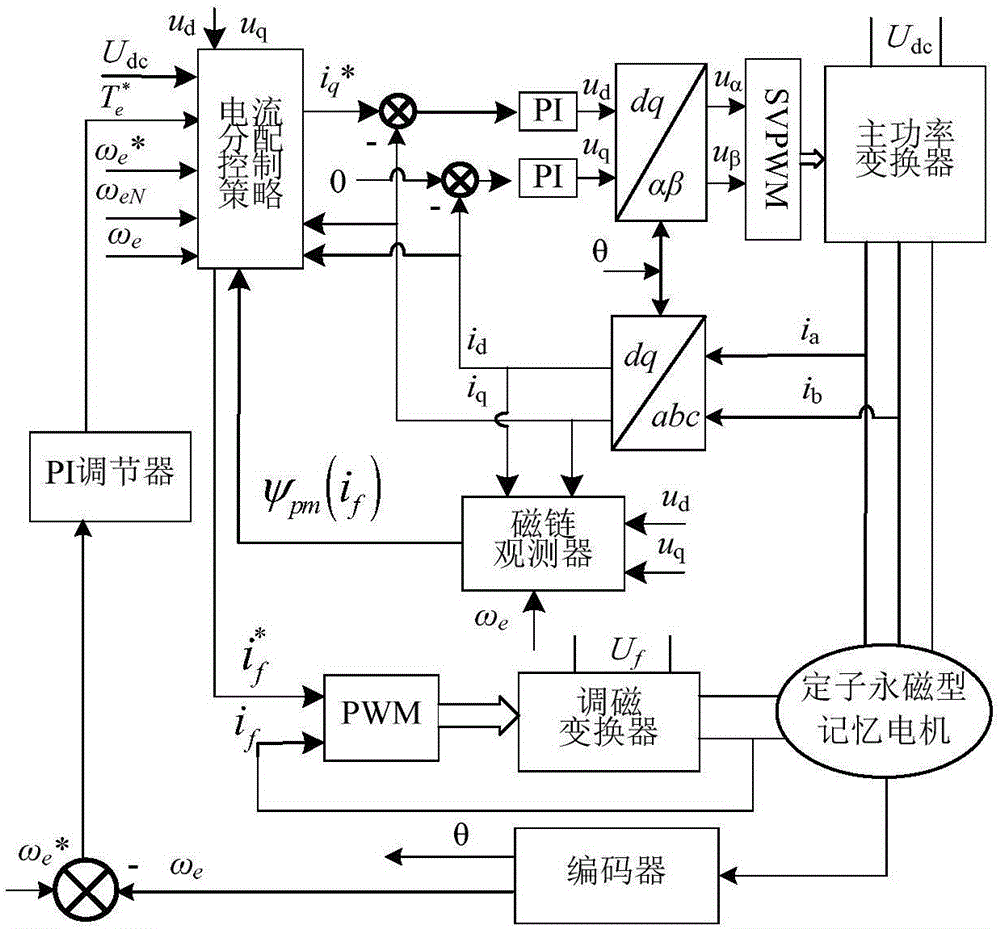

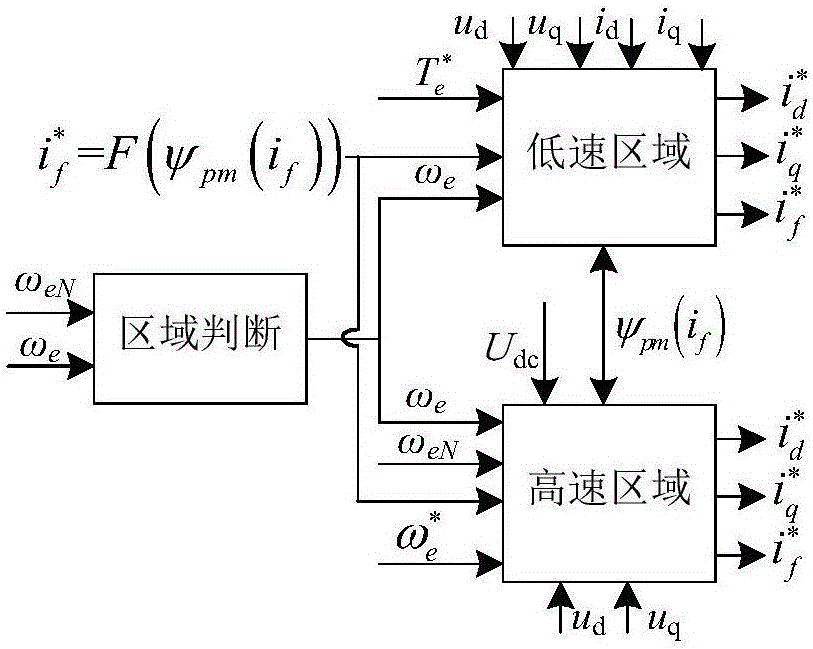

[0034] Such as figure 1 As shown, a stator permanent magnet memory motor drive and online magnetic modulation coordinated control method, the method specifically includes the following steps:

[0035] 1) Use the position sensor to collect the position signal of the motor, and send it to the controller for signal processing to obtain the actual speed ω of the motor e and the rotor position angle θ, then the actual speed of the motor ω e and a given speed After the comparison, the speed deviation signal is obtained, and the signal obtained by the speed regulator is used as the torque given signal.

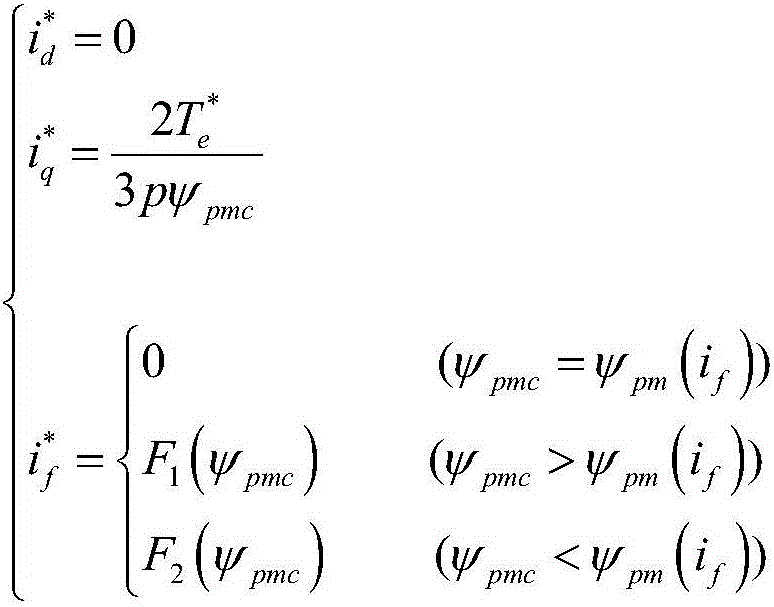

[0036] 2) Collect the phase current i of the main circuit of the motor a and i b and magnetic modulation pulse i f , where the phase current is transformed by Clark and Park to obtain the direct axis current i in the two-phase rotating coordinate system d and quadra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com