Preparation method of waterborne PVDF (Polyvinylidene Fluoride)- PVDF copolymer composite coating membrane

A copolymer and water-based coating technology, which is applied in the direction of separators/films/diaphragms/spacers, electrical components, circuits, etc., can solve problems that are not conducive to product lightweight, low permeability and air permeability, and product production efficiency to improve rate discharge performance and cycle performance, increase swelling rate, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

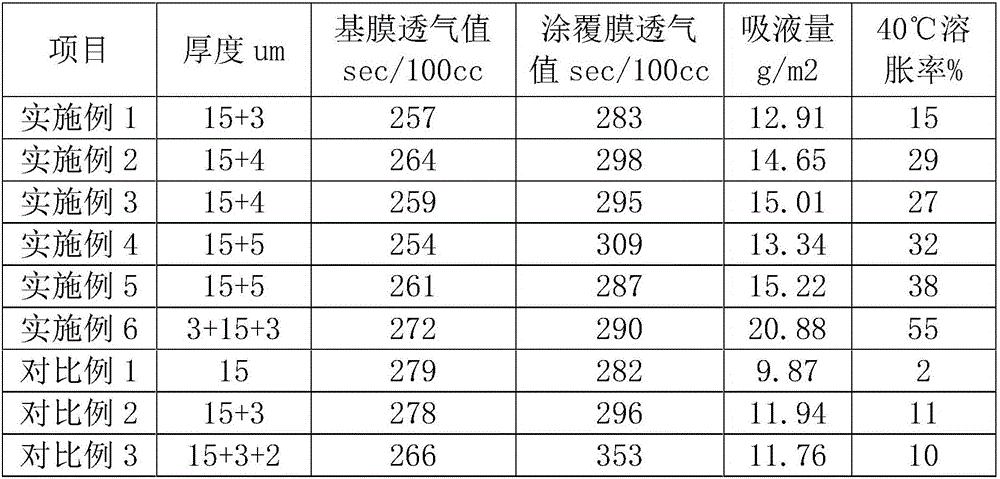

Examples

Embodiment 1

[0021] A preparation method of water-based PVDF and its copolymer composite coating membrane, comprising the following steps:

[0022] 1) Preparation of PVDF and its copolymer and ceramic mixed slurry: Mix and stir 877.8g deionized water and 200g polyvinylidene fluoride to prepare a uniform solution, then add 32.2g sodium polyacrylate and 500g mixed ceramic powder to mix, in Stir evenly at a temperature of 30°C-50°C, and after ball milling for 0.5h, a mixed slurry of PVDF and its copolymer and ceramics is obtained;

[0023] 2) Coating: Coating the PVDF and its copolymers and ceramic mixed slurry prepared in step 1) on one side of a PP film with a thickness of 16 μm by anilox roller coating to form a water-based coating, after being heated at a temperature Dry in a three-stage oven at 40°C-90°C to obtain a water-based PVDF and its copolymer composite coating diaphragm; wherein, the molecular weight of polyvinylidene fluoride is 500,000g / mol, and the thickness of the water-based...

Embodiment 2

[0025] A preparation method of water-based PVDF and its copolymer composite coating membrane, comprising the following steps:

[0026] 1) Preparation of PVDF and its copolymer and ceramic mixed slurry: Mix and stir 1449g deionized water and 59.39g vinylidene fluoride-trifluoroethylene to prepare a uniform solution, then add 1.61g triethyl phosphate and 100g mixed ceramic powder Mix the materials, stir evenly at a temperature of 30°C-50°C, and after ball milling for 0.5h, a mixed slurry of PVDF and its copolymer and ceramics is obtained;

[0027] 2) Coating: The PVDF and its copolymer and ceramic mixed slurry prepared in step 1) are coated on one side of a PP film with a thickness of 15 μm by roll coating to form a water-based coating. Dry in a three-stage oven at 40°C-90°C to obtain a water-based PVDF and its copolymer composite coated separator; wherein, the molecular weight of vinylidene fluoride-trifluoroethylene is 600,000g / mol, and the thickness of the water-based coating...

Embodiment 3

[0029] A preparation method of water-based PVDF and its copolymer composite coating membrane, comprising the following steps:

[0030] 1) Preparation of PVDF and its copolymer and ceramic mixed slurry: Mix and stir 1095g deionized water and 5g vinylidene fluoride-tetrafluoroethylene to prepare a uniform solution, then add 10g ammonium polyacrylate and 500g mixed ceramic powder to mix, Stir evenly at a temperature of 30°C-50°C, and after ball milling for 1 hour, a mixed slurry of PVDF and its copolymer and ceramics is obtained;

[0031] 2) Coating: The PVDF and its copolymer and ceramic mixed slurry prepared in step 1) are coated on one side of a PP film with a thickness of 15 μm by micro-gravure coating to form a water-based coating. Dry in a three-stage oven at 40°C-90°C to obtain a composite coated diaphragm of water-based PVDF and its copolymer; wherein, the molecular weight of vinylidene fluoride-trifluoroethylene is 800,000g / mol, and the thickness of the water-based coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com