Light attenuation device

A light decay and cell technology, applied in photovoltaic power generation, electrical components, climate sustainability, etc., can solve problems such as high cost, increased cost, and impact on single crystal quality, and achieve simple structure, easy operation, appearance and performance. No change in solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

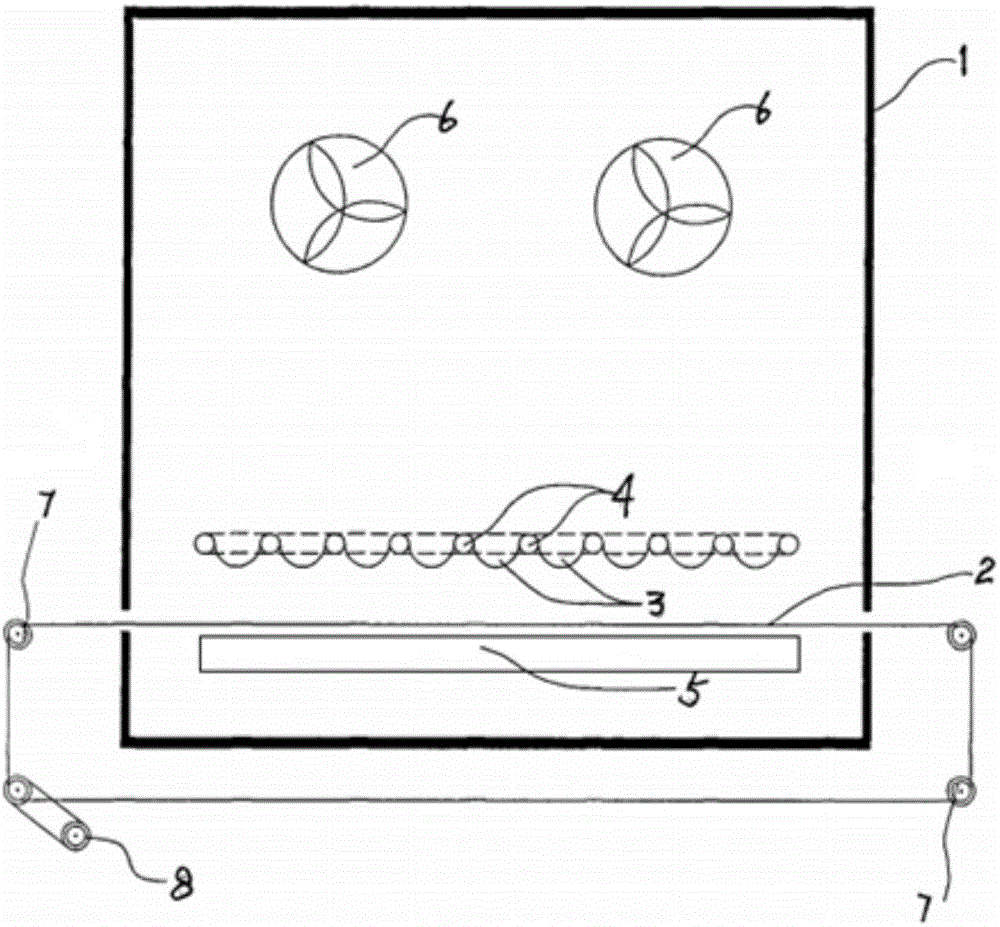

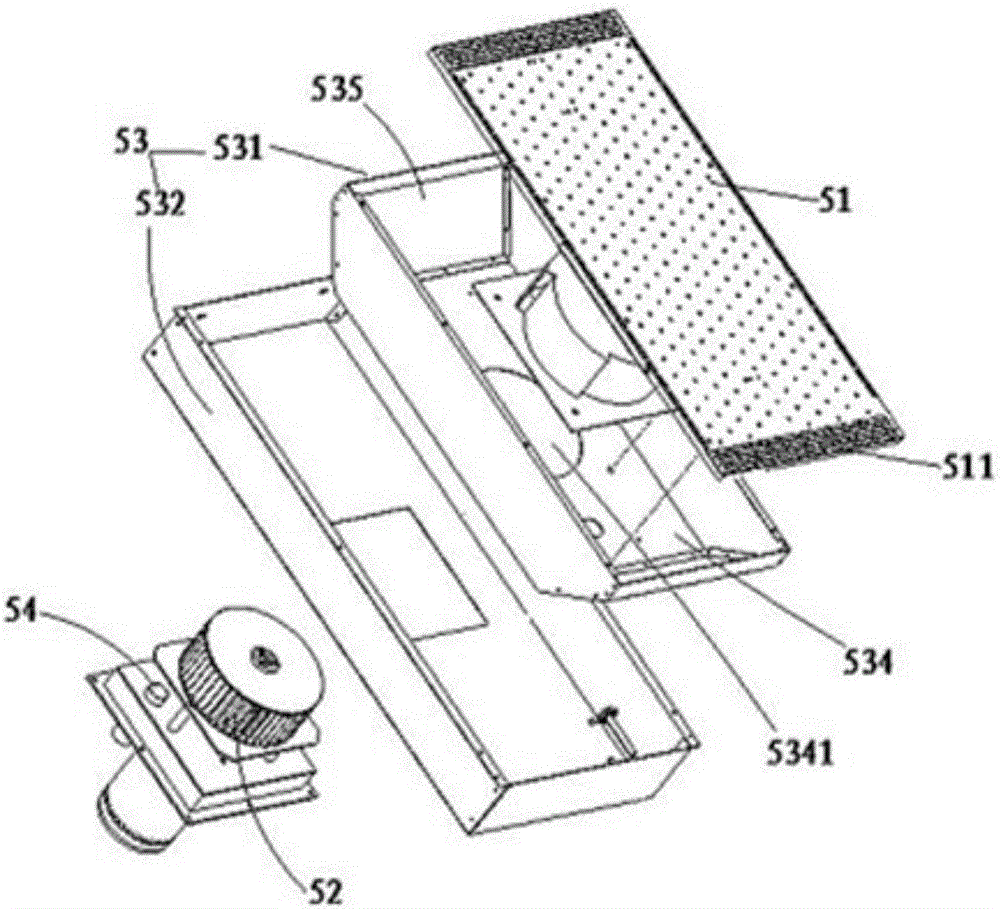

[0021] like figure 1 , figure 2 As shown, a light attenuation device includes an insulated box 1 and a cell conveyor belt, and the working section 2 of the cell conveyor belt passes through the insulated box horizontally. A number of infrared lamps or metal halide lamps 3 and jet tubes 4 are evenly arranged inside the heat preservation box and above the working section 2 of the cell conveyor belt, and the infrared lamps or metal halide lamps 3 and jet tubes 4 are arranged alternately. The pipe wall of the jet pipe 4 is provided with some small holes, which spray air downward; the gas ejected by it is compressed air or nitrogen. A heating device 5 is evenly arranged inside the heat preservation box and below the working section 2 of the cell conveyor belt. figure 1 Among them, 6 is a fan, which is used to adjust the heat flow inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com