A method for manufacturing high-performance and long-life electric wires

A manufacturing method and high-performance technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of unenvironmental protection and low overload capacity of wires, and achieve low power loss, good electrical insulation performance, and strong overload capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

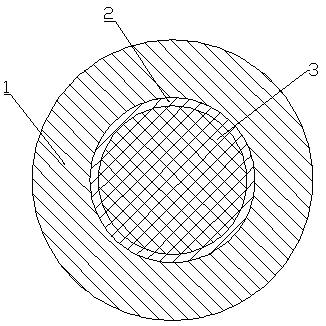

[0022] Example 1, a method of manufacturing high-performance and long-life electric wires, including the steps of wire drawing, co-extrusion, testing, coiling and storage, using copper single wires with a purity greater than 99.99% as the core material 3, and the surface insulation materials include inner layer insulation Material 2 and outer insulation material 1, inner insulation material 2 is silane cross-linked polyethylene material, which is composed of the following materials: low density polyethylene resin 100kg, γ-chloropropyltriethoxysilane 0.5kg, diperoxide 0.2kg of (2-ethyl)hexyl carbonate, 0.3kg of N,N-diphenyl-p-aniline, and 0.2kg of catalyst. Outer insulating material 1 is silane cross-linked halogen-free low-smoke flame-retardant polyolefin insulating material; it is composed of the following materials: 200 kg of silane-grafted polyolefin; 50 kg of melamine polyphosphate; 0.3 kg of N,N-diphenyl-p-aniline; Processing aid 1.5kg; catalyst 0.5kg; anti-copper agent 0...

Embodiment 2

[0028]Embodiment 2, the difference between this embodiment and Embodiment 1 is that the inner insulating material 2 is a silane cross-linked polyethylene material, which is composed of the following materials: 100 kg of low-density polyethylene resin, γ-chloropropyltriethoxysilane 5kg, (2-ethyl)hexyl peroxydicarbonate 2kg, N,N-diphenyl-p-aniline 3kg, catalyst 1kg. Outer insulating material 1 is silane cross-linked low-smoke halogen-free flame-retardant polyolefin insulating material; it is composed of the following materials: silane-grafted polyolefin 200kg; melamine polyphosphate 150kg; N,N-diphenyl-p-aniline 1.2kg; Processing aid 5kg; catalyst 5kg; anti-copper agent 5kg. The thickness of the inner insulating material 2 is 0.15 mm, and the thickness of the outer insulating material 1 is 0.75 mm. During co-extrusion, the extrusion pressure is 80 MPa, the extrusion speed is 100 m / min, and the extrusion temperature is 155°C.

Embodiment 3

[0029] Embodiment 3, the difference between this embodiment and Embodiment 1 is that the inner insulating material 2 is a silane cross-linked polyethylene material, which is composed of the following materials: 100 kg of low-density polyethylene resin, γ-chloropropyltriethoxysilane 3kg, 1kg of (2-ethyl)hexyl peroxydicarbonate, 1.5kg of N,N-diphenyl-p-aniline, and 0.7kg of catalyst. Outer insulating material 1 is silane cross-linked halogen-free low-smoke flame-retardant polyolefin insulating material; it is composed of the following materials: 200 kg of silane-grafted polyolefin; 100 kg of melamine polyphosphate; 0.8 kg of N,N-diphenyl-p-aniline ; Processing aid 3kg; Catalyst 3kg; Anti-copper agent 2.5kg. The thickness of the inner insulating material 2 is 0.12 mm, and the thickness of the outer insulating material 1 is 0.7 mm. During co-extrusion, the extrusion pressure is 75MPa, the extrusion speed is 75 m / min, and the extrusion temperature is 150°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com