Lean production management kanban system and application method

A lean production and production management technology, applied in data processing applications, manufacturing computing systems, instruments, etc., can solve problems such as time-consuming and labor-intensive, no timely alarm processing, complex products, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The invention will be further described in detail below in conjunction with the drawings.

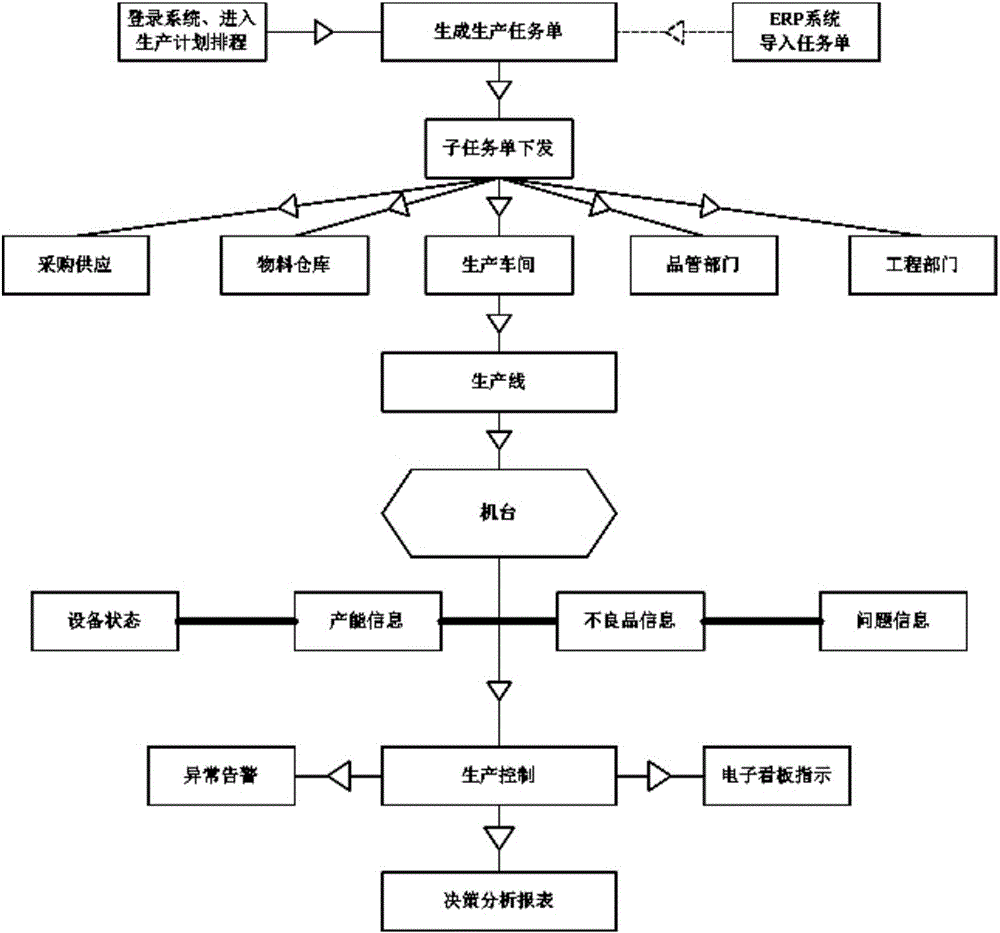

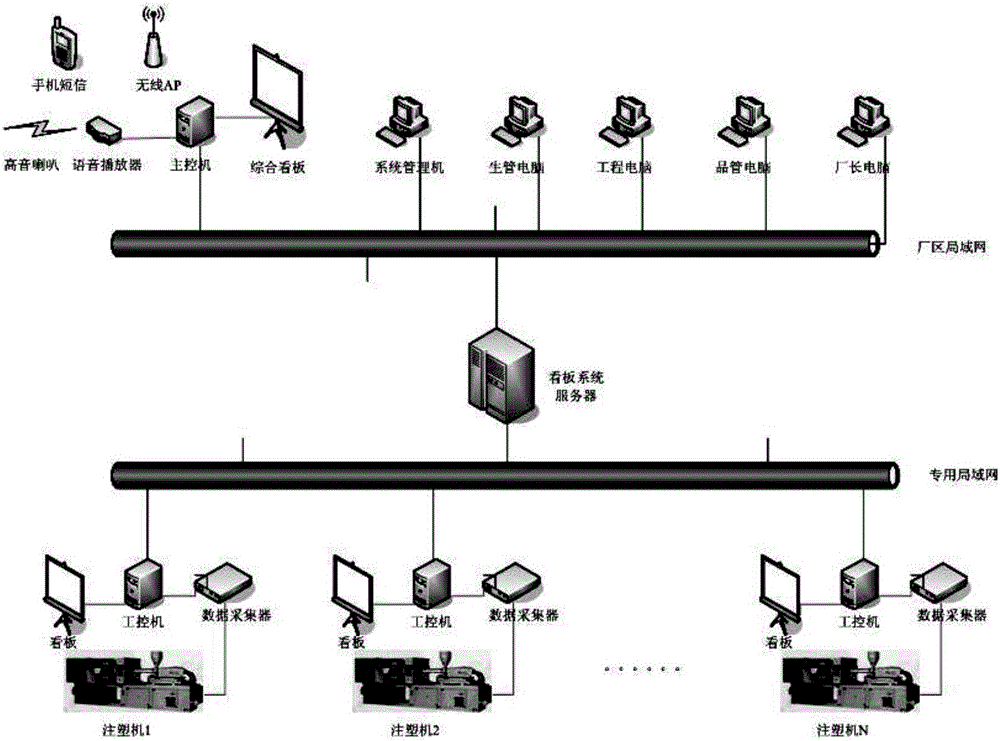

[0042] Such as Figure 1-2 As shown, an electronic kanban system for lean production management, where the system mainly includes machine kanban, integrated kanban, data collector, industrial computer, server, kanban system software, call broadcast system, dedicated LAN, etc., available To implement lean production management in the pulling production of injection molding enterprises. The machine kanban is suspended and installed on the machine (injection molding machine), and production information such as production capacity data, prompts and alarms, and operation drawings are displayed in the form of an electronic kanban at the production site to meet the needs of pulling production management; the integrated kanban is a suspension or Vertically installed in key positions of the production workshop, it displays the production information of all machines in the workshop, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com