A steelmaking-continuous casting-hot rolling integrated scheduling method and system

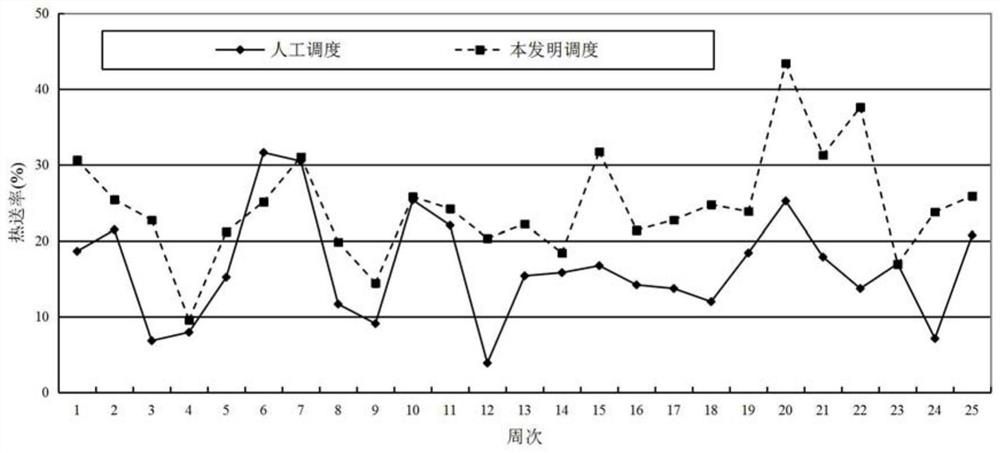

A scheduling method and continuous casting technology, applied in control/regulation systems, manufacturing computing systems, general control systems, etc., can solve the problems of low rolling mill work efficiency, energy waste, and low slab hot delivery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0128] The present invention will be described in detail below in terms of specific embodiments in conjunction with the accompanying drawings. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It is to be noted that other embodiments may be utilized or structural and functional modifications may be made to the embodiments set forth herein without departing from the scope and spirit of the present invention.

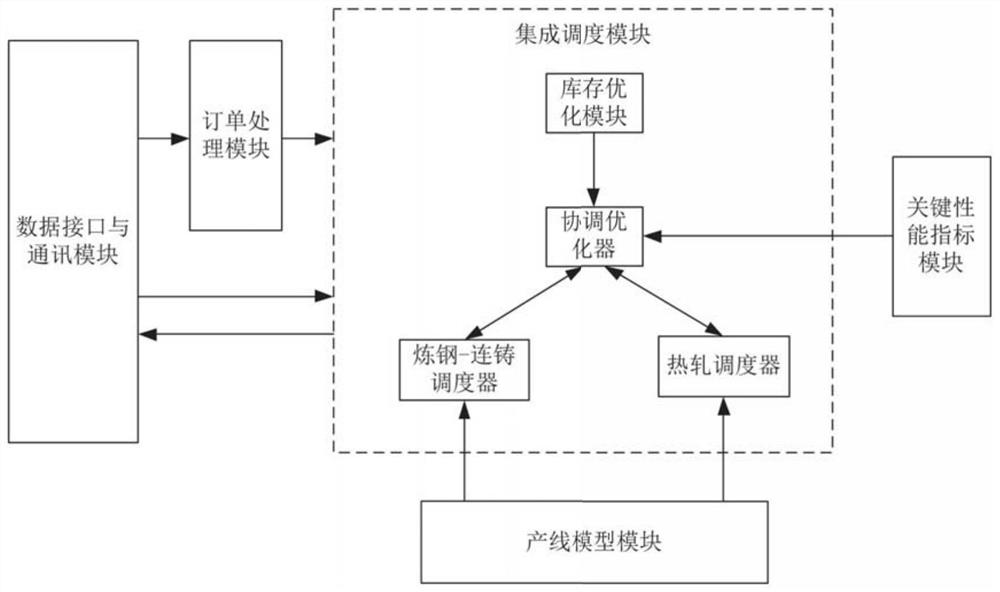

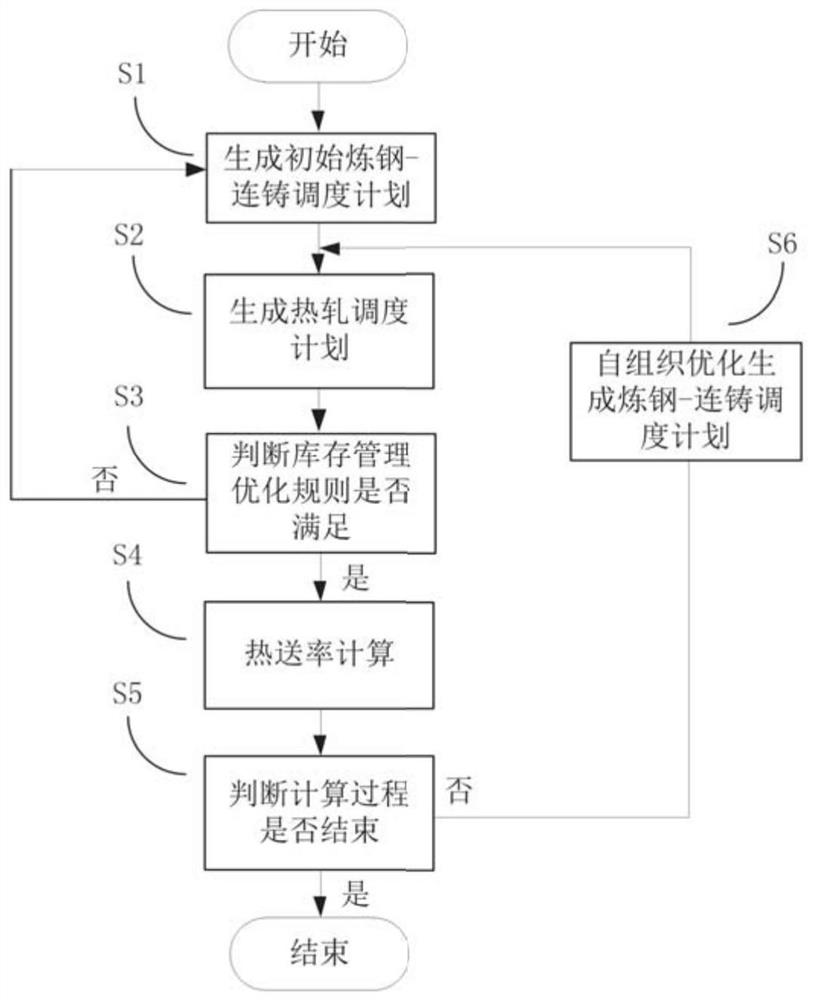

[0129] The optimal scheduling technology of iron and steel production process is an important manufacturing information technology, which plays an important role in improving the production efficiency of iron and steel enterprises, reducing energy / material consumption, improving product quality, and reducing production costs. Steelmaking, continuous casting, and hot rolling are the main links in the steel production process, and steelmaking-continuous casting-hot rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com