Tire noise horn amplifying effect predicting method

A prediction method and speaker technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as poor results, time-consuming calculation, inaccurate prediction of maximum and minimum positions, and a simple method to achieve , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The prediction method of tire noise horn amplification effect in the present embodiment is to carry out as follows:

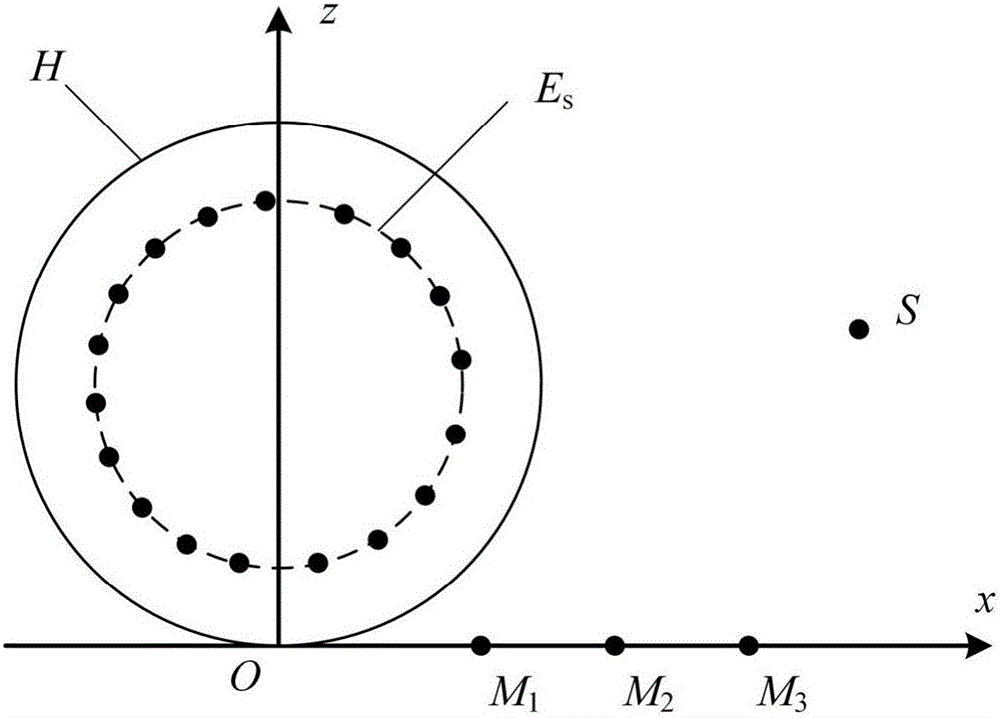

[0047] Step 1, such as figure 1As shown, the tire is simplified as a rigid cylinder, the cylinder is placed on the rigid ground, and the measurement points are arranged in the horn-shaped area formed by the arc surface of the cylinder and the ground. In the specific implementation, the microphone used for measurement is embedded in the ground, and the microphone The surface of the probe coincides with the ground, and a point source S is placed at a certain distance from the cylinder above the ground as the sound source. In the specific implementation, a small speaker is used as the sound source.

[0048] Step 2. Evenly place N nodes on the surface of the cylinder. The sound pressure on the surface of the cylinder is represented by the sound pressure at the N nodes. Arrange N equivalent sources inside the cylinder. The surface where the equivalent source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com