Fully automated biochemical analyzer with dispensing unit

A technology of biochemical analyzer and dispensing unit, which is applied in the field of medical inspection and detection, can solve the problems of cross contamination of reagent needles and sample needles, and achieve the effect of sufficient and effective cleaning, elimination of cross contamination, and good convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

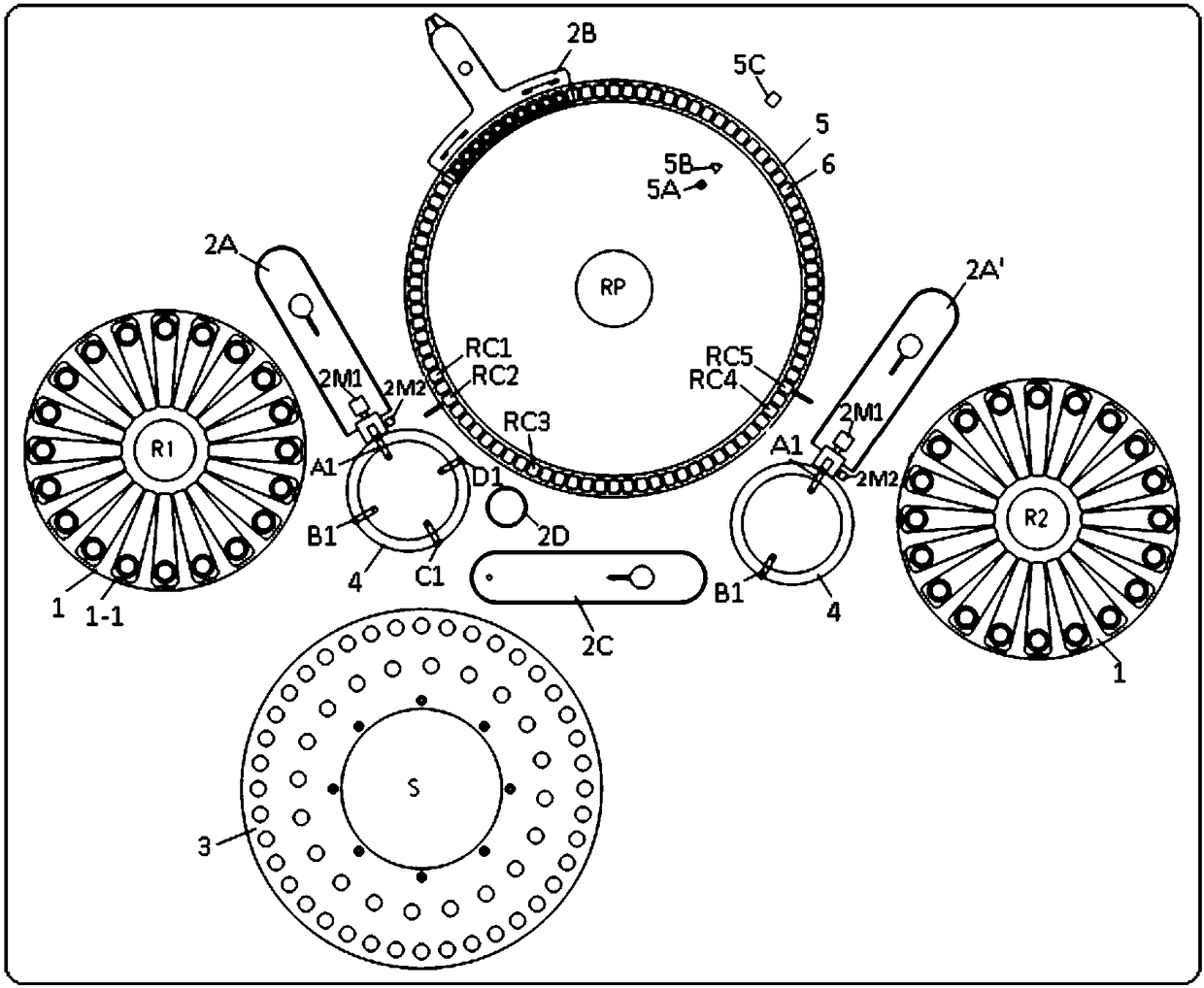

[0041] figure 1 It is an embodiment of the automatic biochemical analyzer with dispensing unit of the present invention.

[0042] The main structure of the instrument includes two reagent trays 1, a reaction tray 5, a sample loading unit, an optical detection unit, a detection cup cleaning unit 2B, two distribution units and a sample needle 2C, and the sample loading unit adopts a circular sample tray 3; The two dispensing units are used to absorb and distribute reagents, and the sample needle 2C is used to absorb samples; a cleaning position 2D is provided beside the sample needle 2C for cleaning the sample needle 2C.

[0043] Wherein, the reagent plate 1 is provided with a plurality of reagent bottles 1-1, the reaction plate 5 is provided with a plurality of detection cups 6, and the optical detection unit includes a light source 5A, a monochromator 5B and an optical signal detector 5C;

[0044] The dispensing unit includes a needle moving arm 2A / 2A', a pipeline converter a...

Embodiment 2

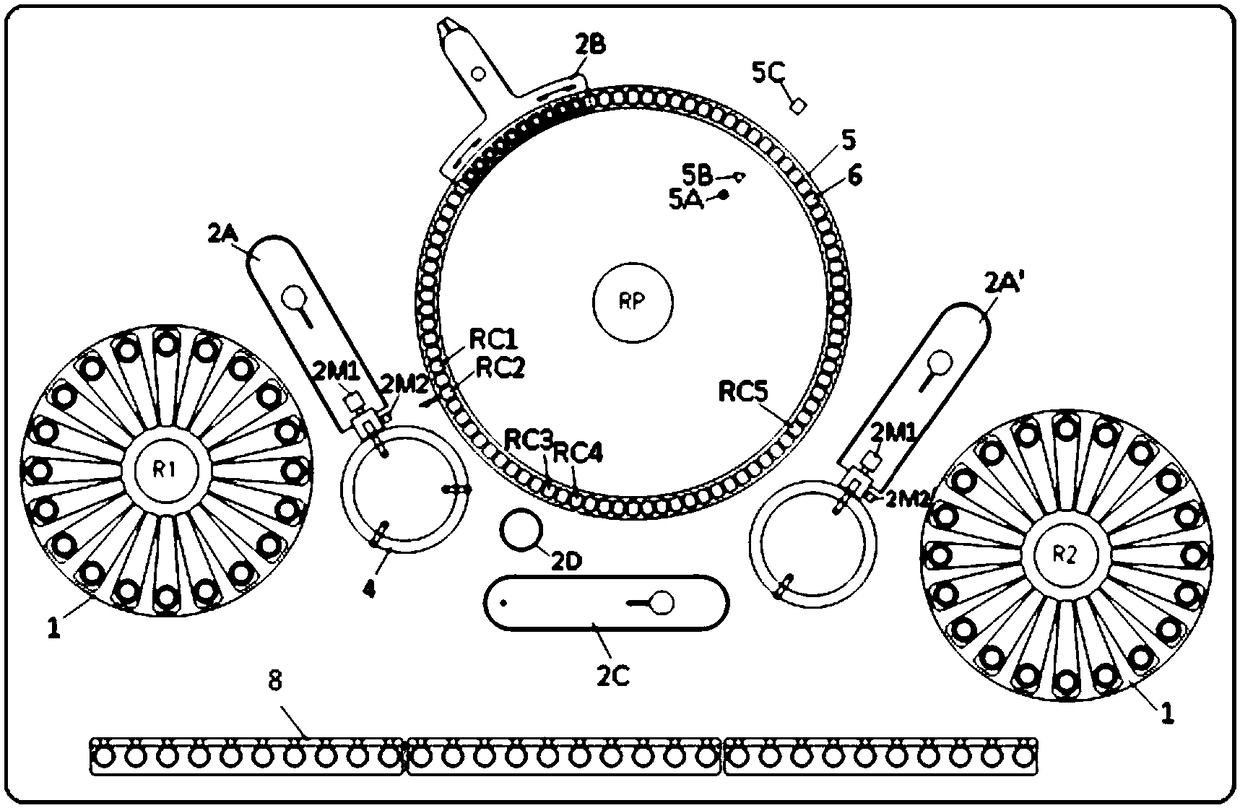

[0053] Such as figure 2 , the difference between this embodiment and embodiment 1 is that the sample loading unit of this embodiment is a track-type sample rack 8, and has two distribution units, and there is a distribution unit near the position of the first reagent disk R1, and the distribution unit The pipeline converter has three needle positions; there is a distribution unit near the second reagent plate R2, and the pipeline converter of the distribution unit has two needle positions.

Embodiment 3

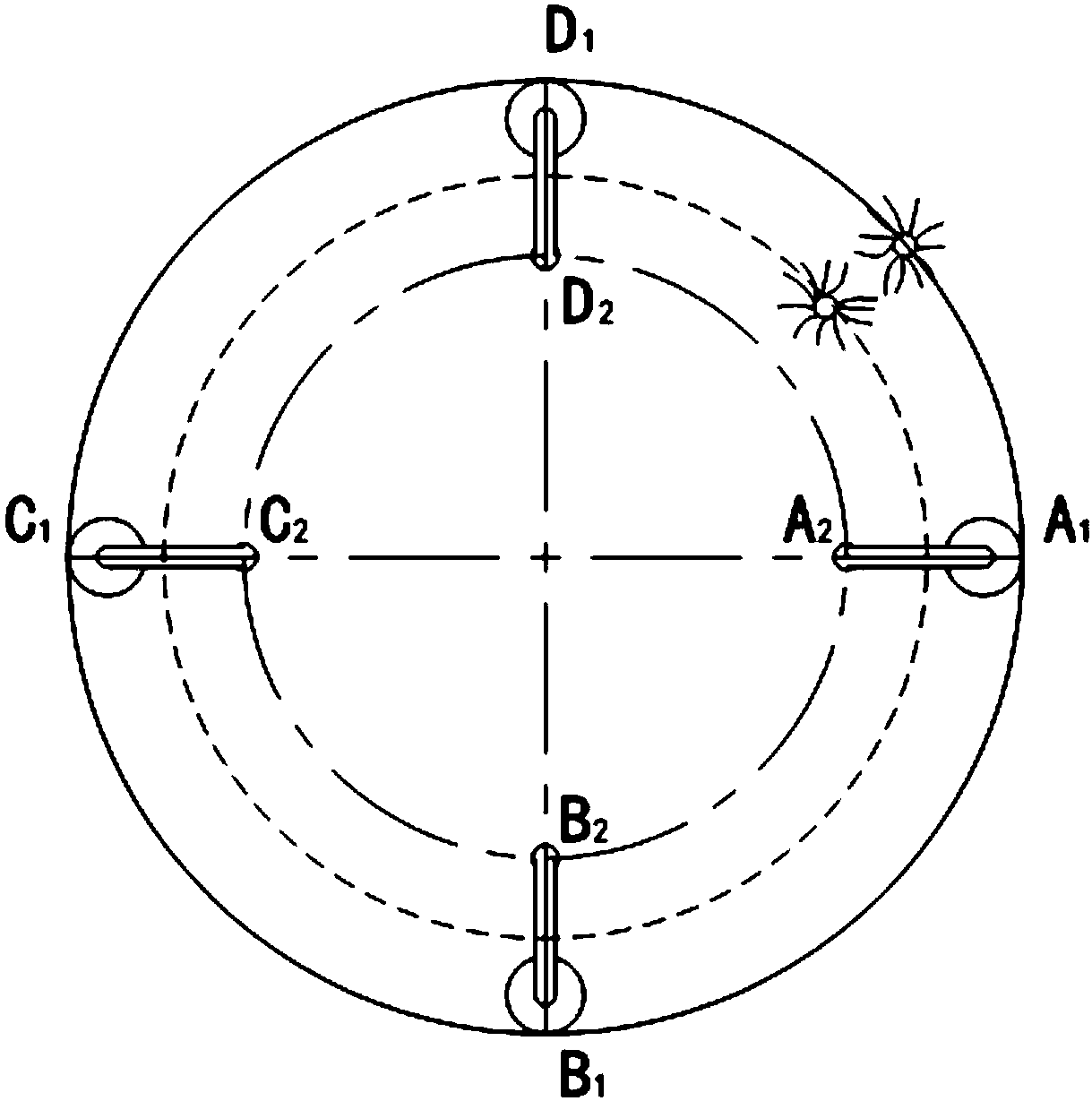

[0055] Such as Figure 3-4 As shown, in this embodiment, the cleaning of the needle in the dispensing unit is not limited to the inside of the needle, but also includes the cleaning of the outside of the needle. The cleaning device for the outside of the needle includes a cleaning agent nozzle 7-9 and a pure water nozzle 7-8, two The nozzles are all pointing to the tip of the hollow needle, and the pure water nozzle 7-8 is higher than the position of the cleaning agent nozzle 7-9. When in use, the cleaning agent is first sprayed to the outside of the hollow needle tip through the cleaning agent cleaning head 7-9, and then through the pure water nozzle. 7-8 Spray pure water to the outside of the hollow needle tip; the rinsed cleaning agent and pure water fall into the waste liquid collection tank below.

[0056] Or, only pure water spout 7-8 is set outside the hollow needle, as Figure 3-5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com