A control method of a constant force jib crane using a vector variable voltage variable frequency frequency converter as a power source

A technology of variable voltage, variable frequency, and control method, which is applied in the direction of load hanging components, transportation, and packaging, etc., and can solve problems such as measurement difficulties, inaccurate results, measurement being affected by installation location and method, and lack of automatic safety control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

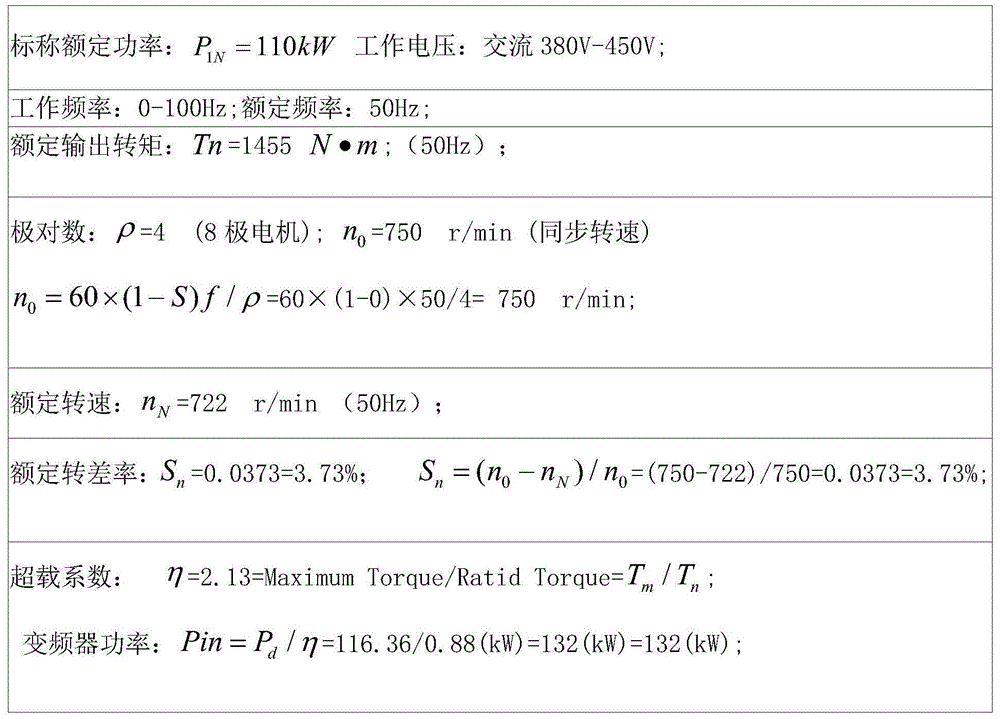

[0101] The control method of the constant-arm crane using the vector variable voltage frequency converter as the power source of this embodiment. It includes the following steps:

[0102] S1: Hoisting motor vector variable voltage and frequency conversion (VT-VVVF is the same below) The inverter controls the hoisting motor to run and start at the starting frequency fqd:

[0103] In this example, the VT-VVVF frequency converter controls the lifting motor according to the starting frequency of 0.5 Hz. The inverter selected in this example automatically selects the startup item;

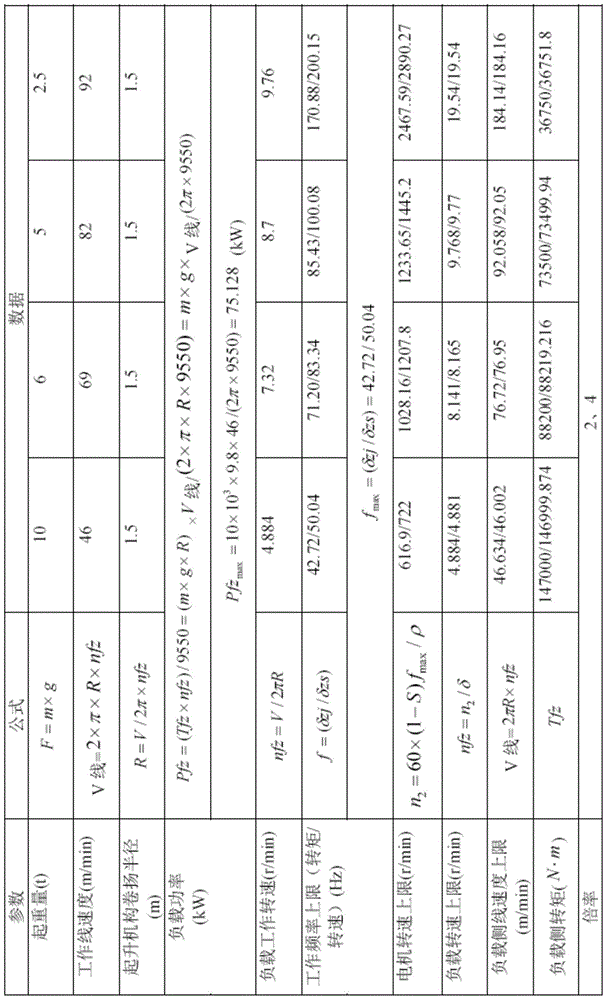

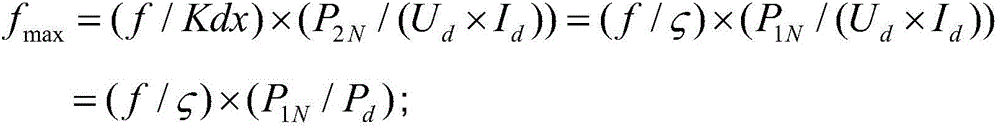

[0104] S2: After the lifting motor is started, gradually increase the output frequency of the inverter to the measurement frequency f. The principle of f is to ensure no overload and stable lifting at the lowest possible frequency. In this case, 15Hz; measure the VT-VVVF inverter of the lifting motor Rectified output DC voltage U d And DC current I d , Which corresponds to DC power P d = U d ×I d When the fl...

Embodiment 2

[0153] The difference between this embodiment and embodiment 1 is that the slip rate of the hoisting motor adopts the corrected slip rate.

[0154] According to: S=S n ×(P d / P dn )×(f 0 / f)………………(3-5);

[0155] or

[0156] The system operating condition parameters of this embodiment are the same as in embodiment 1:

[0157] When the actual VT-VVVF inverter rectified output DC power P d =34.57kW,

[0158] Uncorrected rated slip S n That is, the calculation of rated slip:

[0159] S n =(n 0 -nN) / n 0 =(750-722) / 750=0.0373;

[0160] Slip after correction:

[0161]

[0162] Using the corrected slip ratio S to calculate the output speed of the hoisting motor is: n N = N 0 -S×n 0 =750-0.03712×750=722.16r / min. In actual measurement, the hoisting motor speed is 723r / min. Using the corrected slip rate S is smaller than using the uncorrected rated slip rate Sn to calculate the output speed of the hoisting motor and the actual measured speed error is smaller; it is concluded that the former is us...

Embodiment 3

[0196] The control method of the constant-arm crane using the vector variable voltage frequency converter as the power source of this embodiment. It includes the following steps:

[0197] S1: The hoisting motor vector variable voltage frequency converter controls the hoisting motor to run and start at the starting frequency fqd;

[0198] In this example, the VT-VVVF frequency converter controls the lifting motor according to the starting frequency of 5Hz. The starting frequency is determined by the selected inverter.

[0199] S2: After the lifting motor starts, measure the rectified output DC voltage U of the lifting motor VT-VVVF inverter d And DC current I d , P d = U d ×I d ; When the fluctuation range is less than 10% within 2 seconds, the measurement record VT-VVVF change

[0200] Frequency converter P d And its output frequency f, calculate the hoisting mechanism motor output torque Tfz:

[0201] Tfz=Kdj×Kdx×Kjs×P d / f=Kdj×Kdx×Kjs×(U d ×I d ) / f.....(2-2);

[0202] In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com