Seed sowing and film mulching integrated machine

An all-in-one machine and seed technology, applied in the field of agricultural machinery, can solve the problems of immaturity and difficulty in film-covering agricultural production steps, etc., and achieve the effects of convenient operation, reasonable structure design, and improved operation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

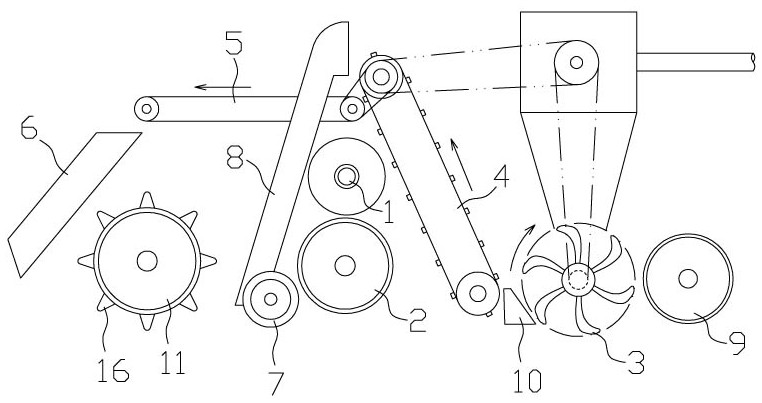

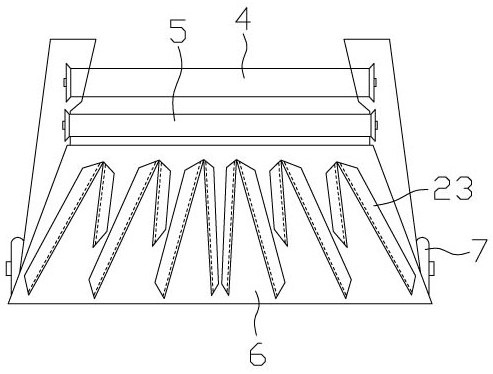

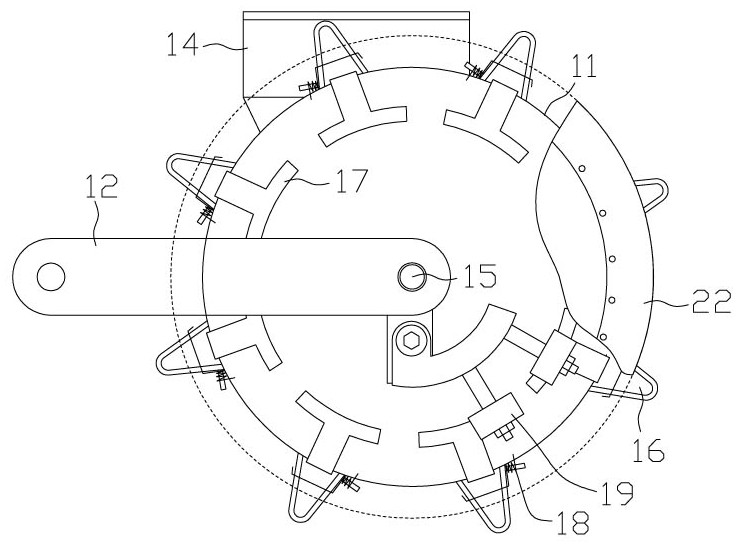

[0013] Such as Figures 1 to 7 As shown, the seed inserting and covering machine includes a film laying device, a soil covering device, an inserting device and a power transmission mechanism installed on the frame. The film laying device includes a film tape roller 1 for placing the film tape and a film tape The film release roller 2 is suppressed and the film tape roll 1 is horizontally rotatably fixed on the frame, and the film release roller 2 is rotatably arranged below the film tape roll 1, and the film tape on the film tape roll 1 is downward from the front. Lay it on the ground after bypassing the film release roller 2. The soil covering device includes a rotary cutter roller 3, a belt elevator 4, a conveyor belt 5 and a soil distributor 6. The rotary cutter roller 3 is placed in front of the film release roller 2. The belt type The hoist 4 is arranged obliquely between the rotary cutter roller 3 and the film release roller 2 to lift the soil lifted by the rotary cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com