Comprehensive sensory quality evaluation method for tea leaves

A sensory quality and evaluation method technology, applied in the field of comprehensive sensory quality evaluation of tea, can solve problems such as the practical limitations of standard ratings, high taste bud stimulation intensity, and large differences, to achieve objective and accurate comprehensive sensory quality of tea, simplified scoring methods and Coefficient calculation, ease of calculation and comparison of grading effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Take 5.0 grams of Gongfu black tea sample, put it in the evaluation cup, add 250 ml of boiling water, keep the tea water ratio at 1:50 (g / ml), and cover it.

[0031] Take an appropriate amount of Gongfu black tea sample and observe the shape. Tea leaves are reviewed for shape, tenderness, colour, evenness and clarity. The tea splines are fat and strong, with tight knots, more front and seedlings, uniform, high clarity, dark brown and oily color, and golden hair is revealed.

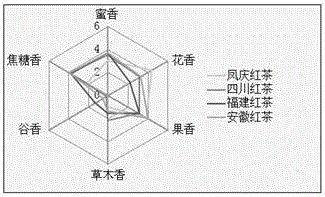

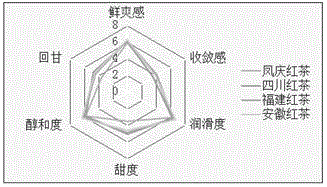

[0032] Steep bubble method to make tea soup. Sampling 5.0 grams, put it in the review cup, add boiling water to keep the ratio of tea to 1:50 (g / ml), and cover it. After 5 minutes of timing, filter the tea soup into the evaluation tea bowl, leave the bottom of the leaves in the cup, and evaluate in the order of hot smell, soup color, warm smell, taste, cold smell, and leaf bottom. No soup is dark or cloudy, or smells unpleasant pungent odors such as non-tea smell, burnt, watery stuffi...

Embodiment 2

[0035] Example 2: Take 5.0 grams of green tea sample, put it in the evaluation cup, add 250 ml of boiling water, keep the tea water ratio at 1:50 (g / ml), and cover it.

[0036] Take an appropriate amount of green tea sample and observe the shape. Tea leaves are reviewed for shape, tenderness, colour, evenness and clarity. The tea sample is even, with slightly tender stems, fat, tender and firm, with Miao peaks, dark green color, and exposed pekoe.

[0037] Steep bubble method to make tea soup. Sampling 5.0 grams, put it in the review cup, add boiling water to keep the ratio of tea to 1:50 (g / ml), and cover it. After 4 minutes of timing, filter the tea soup into the evaluation tea bowl, leave the bottom of the leaves in the cup, and evaluate in the order of hot smell, soup color, warm smell, taste, cold smell, and leaf bottom. flawless.

[0038] Brewing tea soup. Another 5.0 grams of tea samples were taken and placed in the review cup, and boiling water was added to keep t...

Embodiment 3

[0040] Example 3: Take 5.0 grams of Pu'er cooked tea sample, put it in the evaluation cup, add 250 ml of boiling water, keep the tea water ratio at 1:50 (g / ml), and cover it.

[0041] Take an appropriate amount of Pu'er tea cooked tea samples and observe the shape. Tea leaves are reviewed for shape, tenderness, colour, evenness and clarity. The tea is uniform, with tender stems, still tightly knotted, brown in color, and still obvious.

[0042] Steep bubble method to make tea soup. Sampling 5.0 grams, put it in the review cup, add boiling water to keep the ratio of tea to 1:50 (g / ml), and cover it. After 5 minutes of timing, filter the tea soup into the evaluation tea bowl, leave the bottom of the leaves in the cup, and evaluate in the order of hot smell, soup color, warm smell, taste, cold smell, and leaf bottom. flawless.

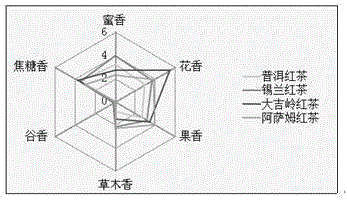

[0043] Brewing tea soup. Another 5.0 grams of tea samples were taken and placed in the review cup, and boiling water was added to keep the ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com