Recyclability quality evaluation method for parts with infinite life design

A technology for quality evaluation and parts, applied in the field of recyclability quality evaluation, to achieve the effects of huge economic value, resource saving and energy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

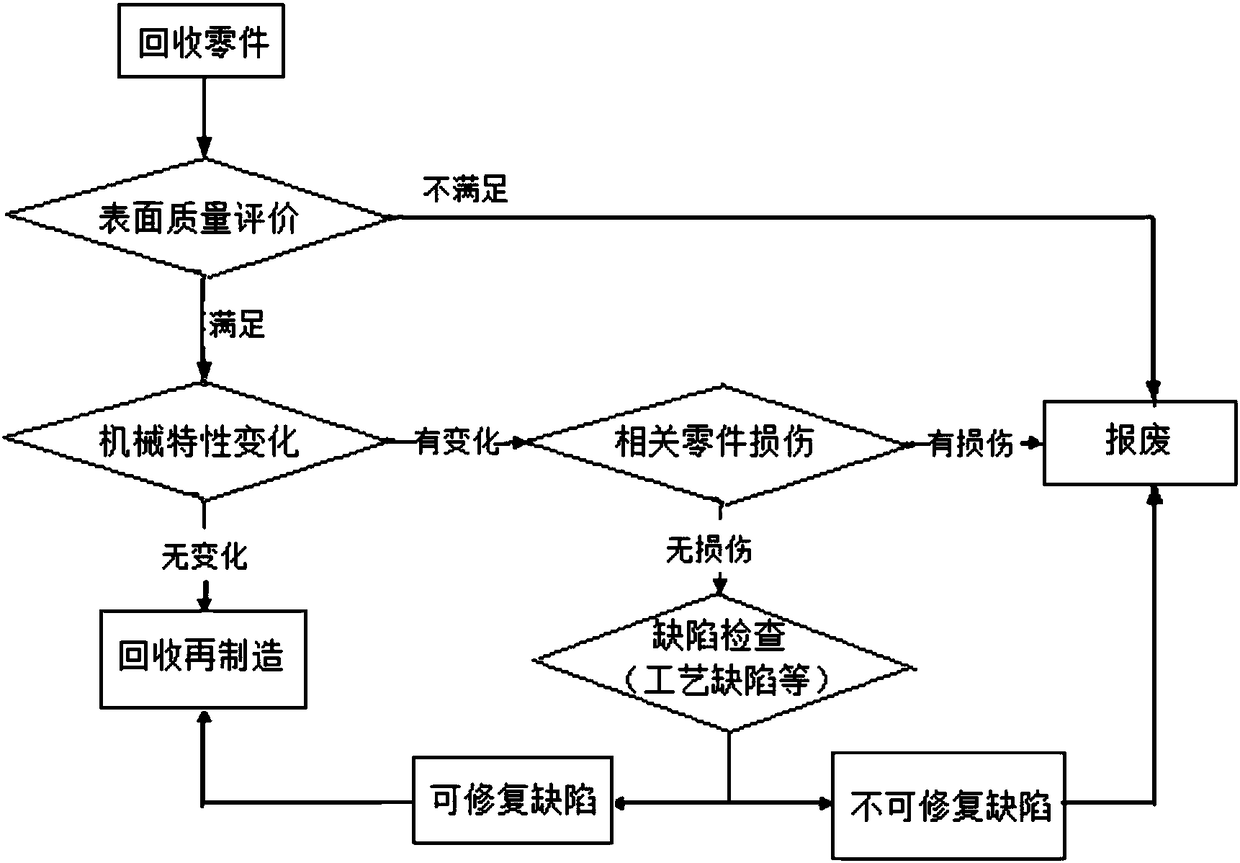

[0022] Such as Figure 5 As shown, the recyclability quality evaluation method under the part infinite life design of the present invention comprises:

[0023] 1. Estimation of strength design margin of recycled parts;

[0024] 2. Evaluation of surface quality such as wear and corrosion of recovered parts;

[0025] 3. Testing of mechanical properties such as hardness, frequency, and stiffness of parts;

[0026] 4. Detection of unexpected defects in the manufacturing process of recycled parts;

[0027] 5. Residual strength and remaining life evaluation of recycled parts.

[0028] Examples:

[0029] Taking the original and recycled piston rod body of a construction machinery hydraulic cylinder as the object, such as figure 1 shown. exist figure 1 Among the piston rods, 001# is the original unused new piston rod, and 002#, 003# and 004# are the recovered piston rods. The piston rod body includes the shaft and earrings, the earrings and the shaft are integral forgings, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com