Two-door-opening type preheating furnace

A preheating furnace and open-door technology, applied in the field of two-door preheating furnaces, can solve the problems that the internal temperature of the equipment cannot be kept stable and uniform, the preheating effect is not ideal, the structure is too simple, etc., and the preheating effect is good and the maintenance The temperature is stable and the effect of ensuring the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

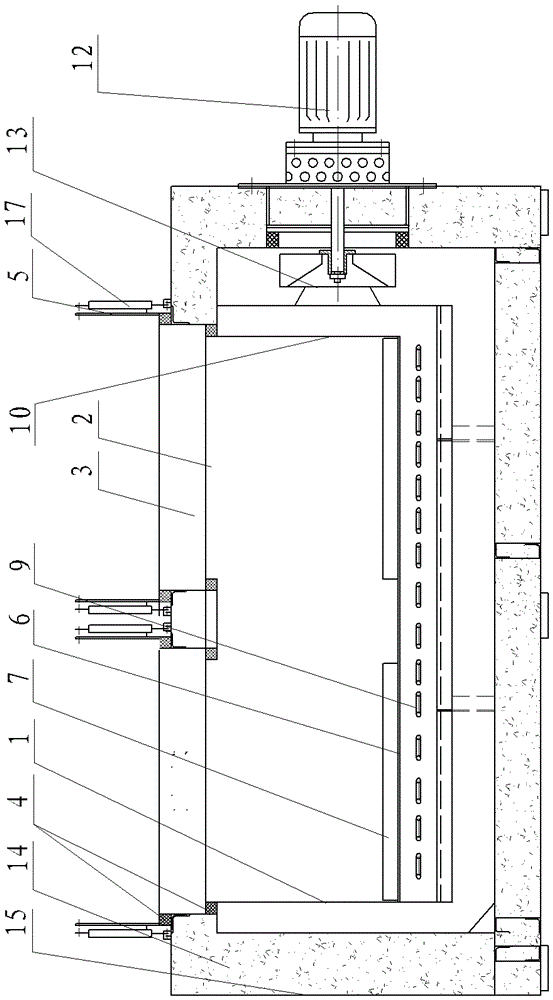

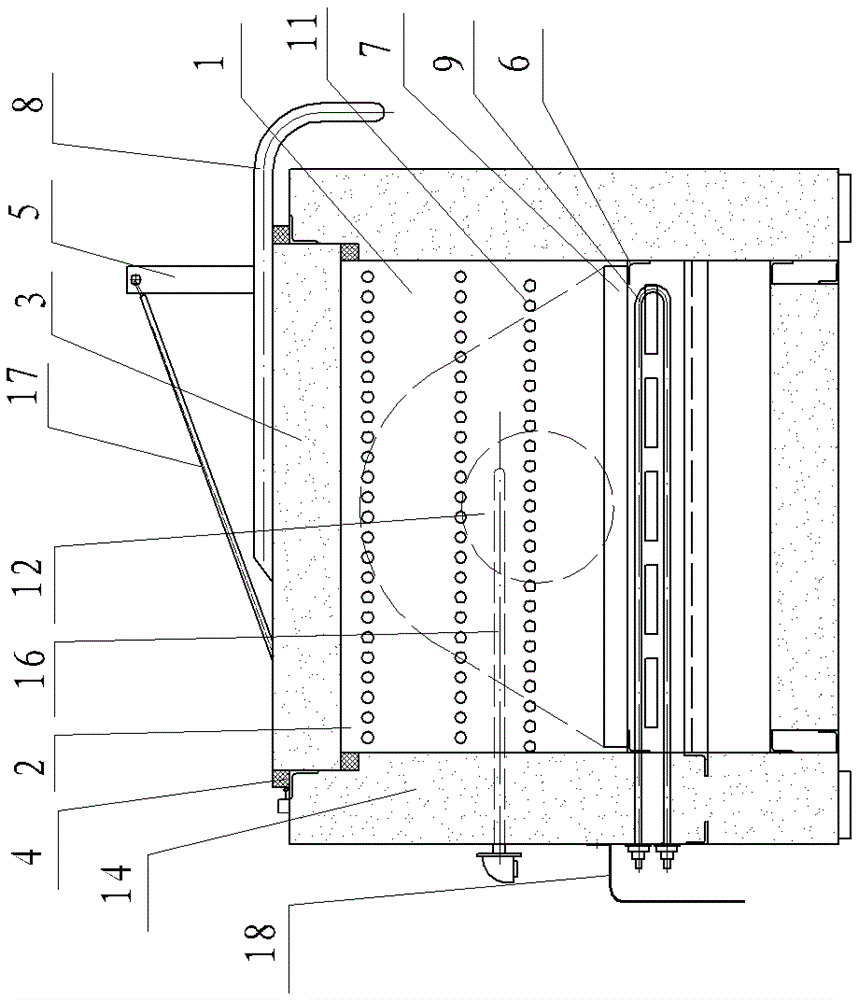

[0013] See figure 1 , figure 2 As shown, a two-door type preheating furnace includes a furnace 1, two inlet and outlet openings 2 are opened on the upper end of the furnace 1, a furnace door 3 is installed on the inlet and outlet opening 2, and two layers of graphite are arranged at the inlet and outlet opening 2. Packing sealing ring 4, a 180 mm thick aluminum silicate cotton insulation layer is arranged in the furnace door 3, a support shelf 6 is installed on the inner wall of the furnace 1, and a shelf 7 is supported by the support shelf 6, and a shelf 7 is provided at the lower end of the shelf 7. The electric heating pipe 9 is provided with an air equalizing plate 10 on one side of the furnace 1, and the air equalizing plate 10 is uniformly provided with ventilation holes 11, and the outside of the air equalizing plate 10 is equipped with a blowing blade 13 connected to a motor 12.

[0014] The outside of the furnace 1 is installed on the furnace body frame 15 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com