Scrap steel preheating system for electric arc furnace

A technology for electric arc furnaces and scrap steel, applied in the direction of preheating costs, furnaces, furnace components, etc., can solve the problems of large investment in equipment and workshops, unsatisfactory preheating effect, large investment in equipment and workshops, etc., and achieve reliability assurance and operating costs, simple and reliable equipment mechanism, and good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

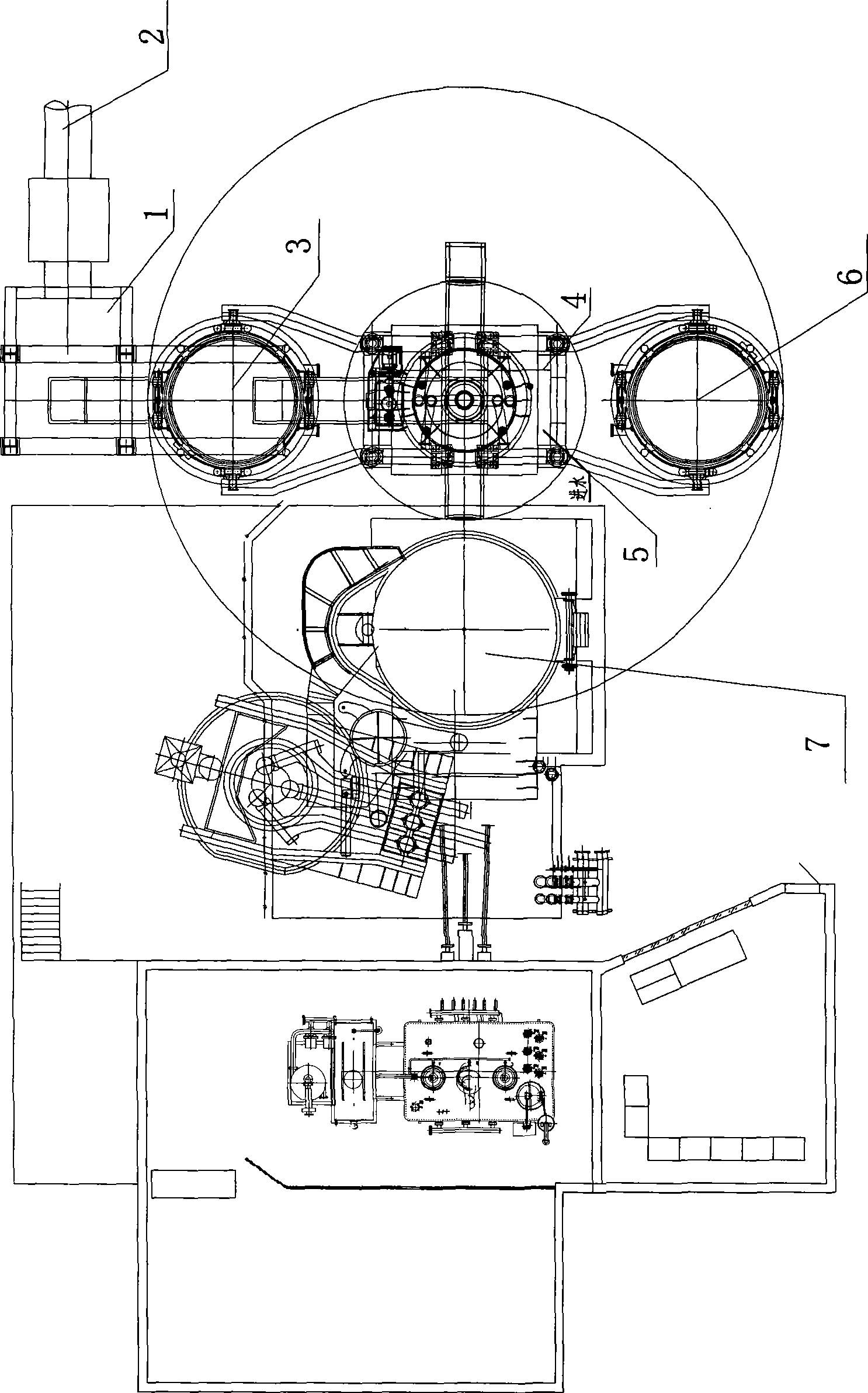

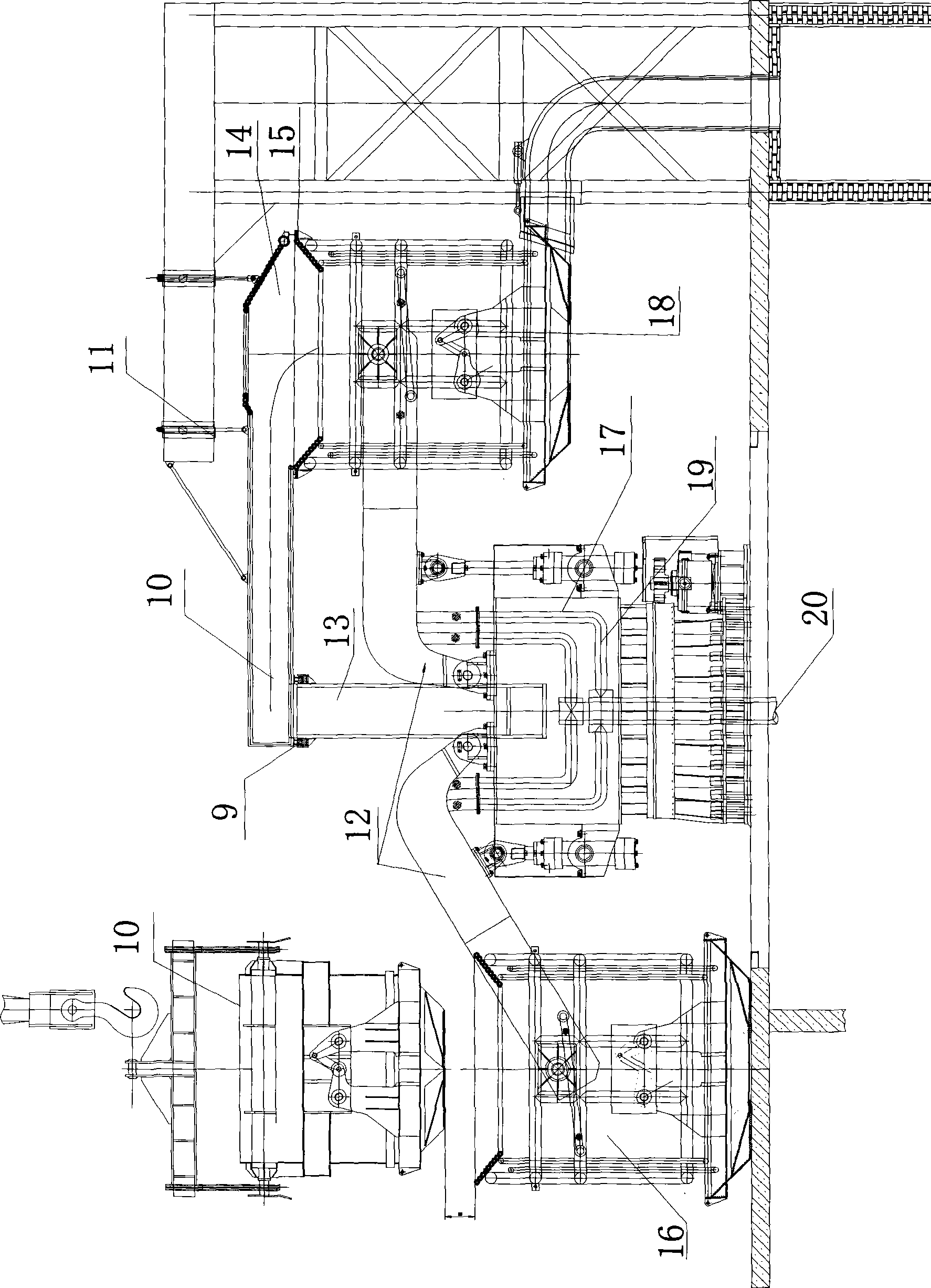

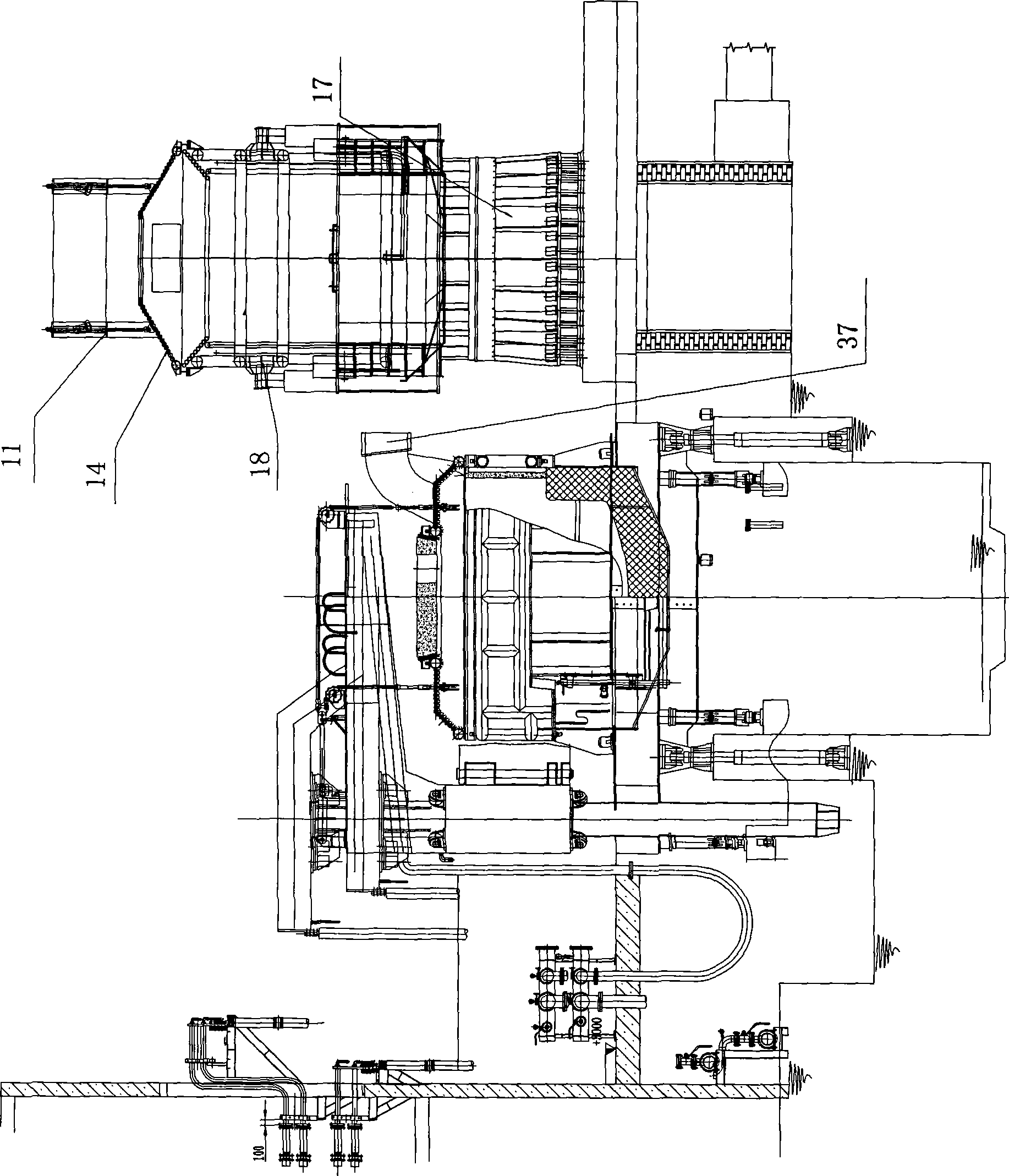

[0030] The present invention is a completely new type of structure and scrap steel preheating system, which is novel and unique in design, simple in structure, and compact in process layout. H-beam structure, on-line (or off-line) through the special structure of the material basket to preheat the steelmaking raw material - scrap steel, and then the special structure of the material basket under the action of a special mechanism, directly put the scrap steel into the electric arc furnace. see figure 1 , figure 2 with image 3 , comprising a scrap steel preheating basket mechanism 18 and a basket rotating and swinging mechanism 17, the basket rotating and swinging mechanism 17 is respectively connected with the scrap steel preheating basket mechanism 16 and the scrap steel preheating basket mechanism 16 and The scrap steel preheating basket mechanism 18 is connected, and a high temperature flue gas water cooling flue 37 and a scrap steel preheating cap 14 are arranged betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com