Transmission device of subway engineering vehicle drive gear box

A technology for subway engineering vehicles and transmissions, which is applied to gear transmissions, transmissions, transmission control, etc., can solve the problems of reducing the service life of the driving device, dragging with gears, and the hazards of the driving device, so as to avoid waste, Improve work efficiency and save energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention. Detailed implementation modes and specific operation procedures are given, but the protection scope of the present invention is not limited to the following Mentioned examples.

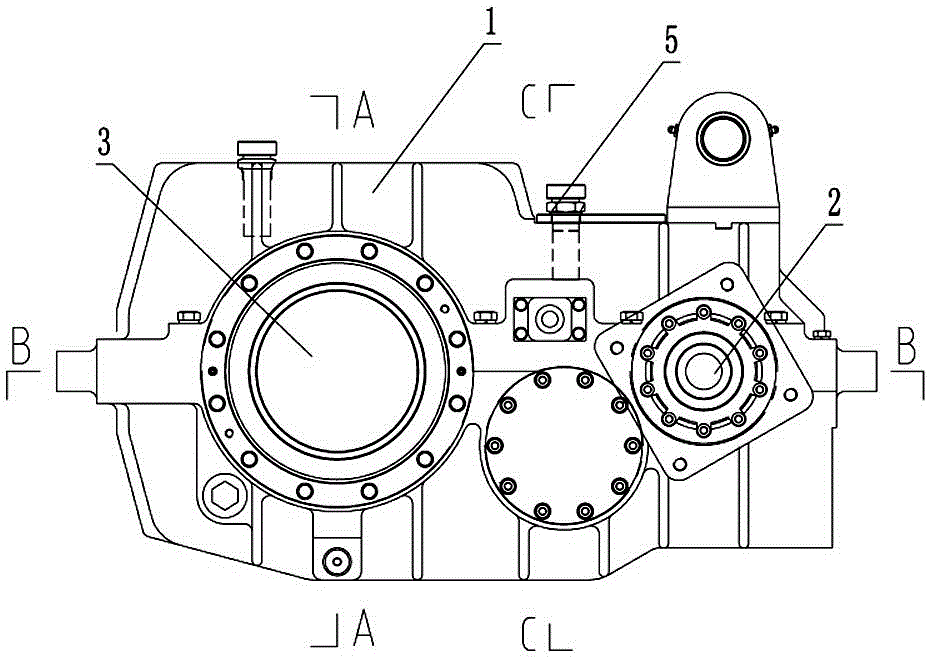

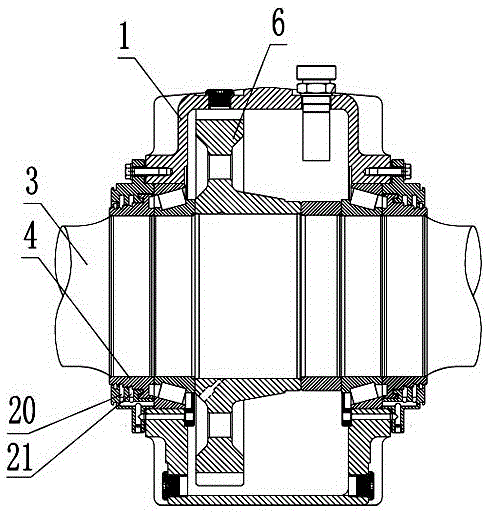

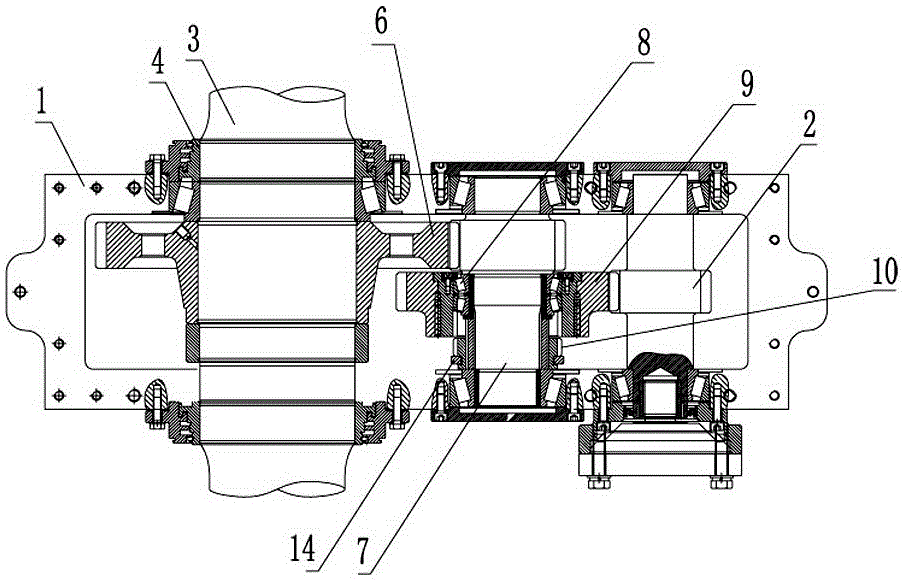

[0017] Such as Figure 1-5 As shown, the driving gearbox transmission device of the subway engineering vehicle of the present invention includes a gearbox body 1, and a power input gear shaft 2 and an axle 3 are arranged in the gearbox body 1 through a bearing body. The two ends of the axle 3 pass through The double-sealed combination and two oil-return channel labyrinth seal ring 4 extends out of the gear box body 1. A breathable cap 5 is arranged on the wall of the gear box body 1; the interference fit of the axle 3 is covered with a first transmission gear 6, a gear box A transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com