Air foam flooding oil-extraction well site device and air foam flooding oil-extraction well site technology

A technology for air foam flooding and oil production, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of high labor intensity and potential safety hazards, and achieve simple construction, process optimization, safe and environmentally friendly operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

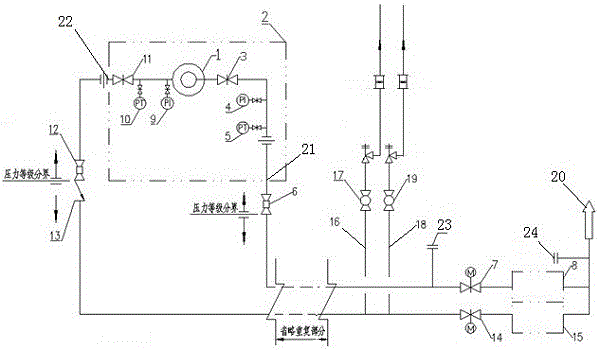

[0035] In order to overcome the technical problems of high labor intensity and potential safety hazards for air foam flooding personnel, this embodiment provides a method such as figure 1 and figure 2The shown air foam flooding oil production well site device and its technology, the oil production wellhead 1 is connected to the oil production tree 2, the oil pipe outlet 21 and the casing gas outlet 22 are arranged on the oil production wellhead 1, the oil pipe and the oil pipe outlet of the oil production wellhead 1 21 is connected, the oil pipe outlet 21 is connected to the well site ball throwing device area 8 through the pipeline, the casing of the oil production wellhead 1 is connected with the casing gas outlet 22, and the casing gas outlet 22 is connected to the casing gas constant pressure degassing area 15 through the pipeline, The wellsite ball throwing device area 8 is connected to the casing gas constant pressure release area 15 through pipelines and leads to the o...

Embodiment 2

[0044] On the basis of Embodiment 1, this embodiment provides an air foam flooding oil production well site device and its technology. A shut-off valve 1 3 and a pressure gauge 1 4 are arranged between them, and a pressure gauge 2 9 and a shut-off valve 2 11 are arranged in sequence between the casing of the oil production wellhead 1 and the casing gas outlet 22.

[0045] The first shut-off valve 3 and the second shut-off valve 11 are manual shut-off valves, which can be manually closed when the device is abnormal. The cut-off valve 3 6 adopts a high-low pressure emergency cut-off valve with an electric actuator, which can not only sense the pipeline pressure through the pressure pipe of the valve body, automatically shut down, but also shut down through the command sent by the signal line. The cut-off valve 412 adopts a mechanical high-low pressure emergency cut-off valve, which senses the pipeline pressure through the pressure-taking pipe of the valve body, and automatically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com