A kind of lightweight preform and preparation method thereof

A prefabricated, lightweight technology, applied in the manufacture of tools, buildings, building components, etc., can solve problems such as low hollow rate, uneven stiffness, and unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following will be further explained to the present invention in detail.

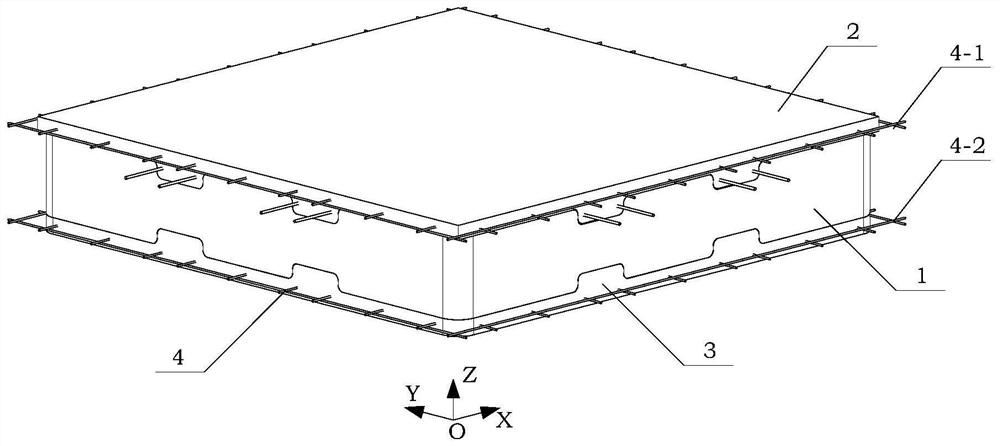

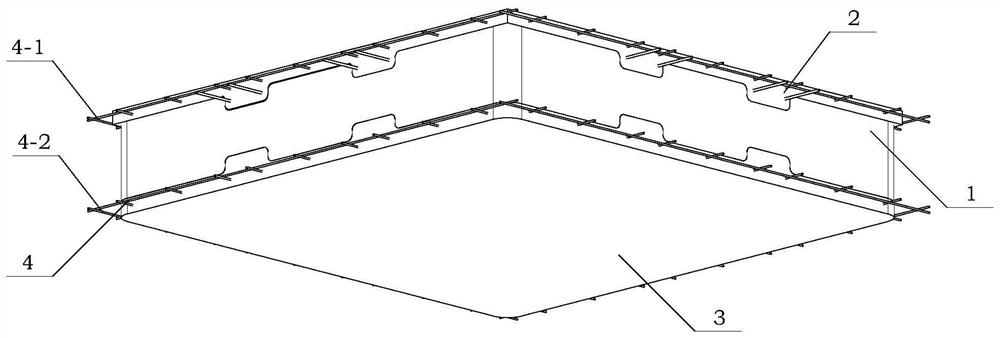

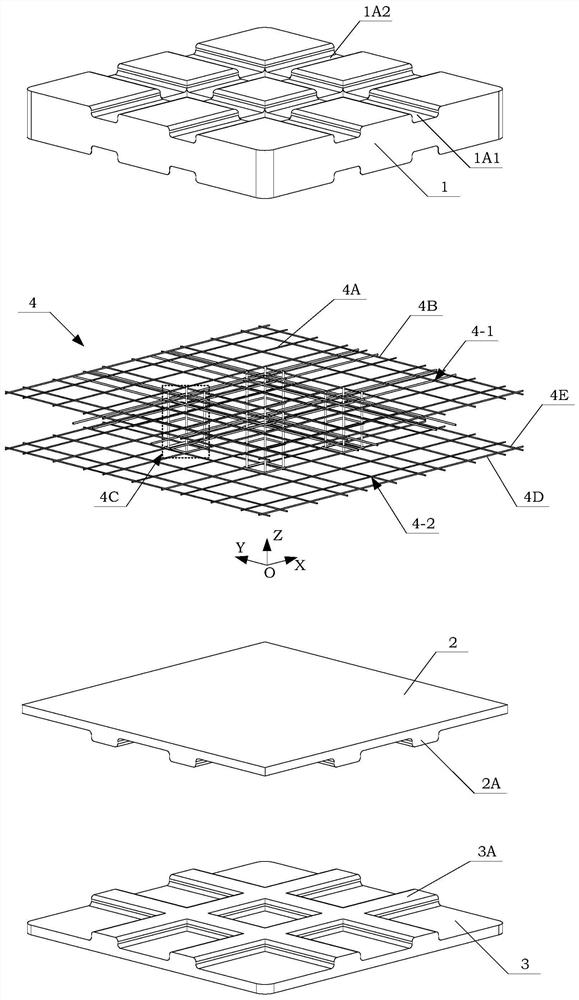

[0045] See figure 1 As well as Figure 1A As well as Figure 1B As well as Figure 1C It shows that the present invention designs a light -quality prefabricated body that can be applied to prefabricated housing buildings. The light -quality prefabricated body can be a substrate for making wall plates or floor panels or roof panels. Body 1, upper layer plate 2. The lower layer board 3 and reinforcement component 4. Another lightweight prefabricated body includes solid lightweight matrix 5, upper layer plate 2, lower layer 3, and steel bar component 4. The reinforced component 4 is obtained by the binding point of the steel bars paved in three directions.

[0046] The upper reinforcement mesh in the reinforced component 4 is located above the matrix (1, 5), and the lower reinforced mesh 4-2 in the reinforced component 4 is below the substrate (1, 5). Pillar reinforced 4C passes through the rectangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com