Heat preservation plate with reinforcing bars and heat preservation structure construction method of heat preservation plate with reinforcing bars on outer wall concrete part

A construction method and thermal insulation board technology, which is applied in thermal insulation, building structure, building components, etc., can solve problems such as high construction technical requirements, potential safety hazards in use, and damage to external facades, so as to reduce the workload of formwork removal and save energy. The effect of steel consumption and consumption saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

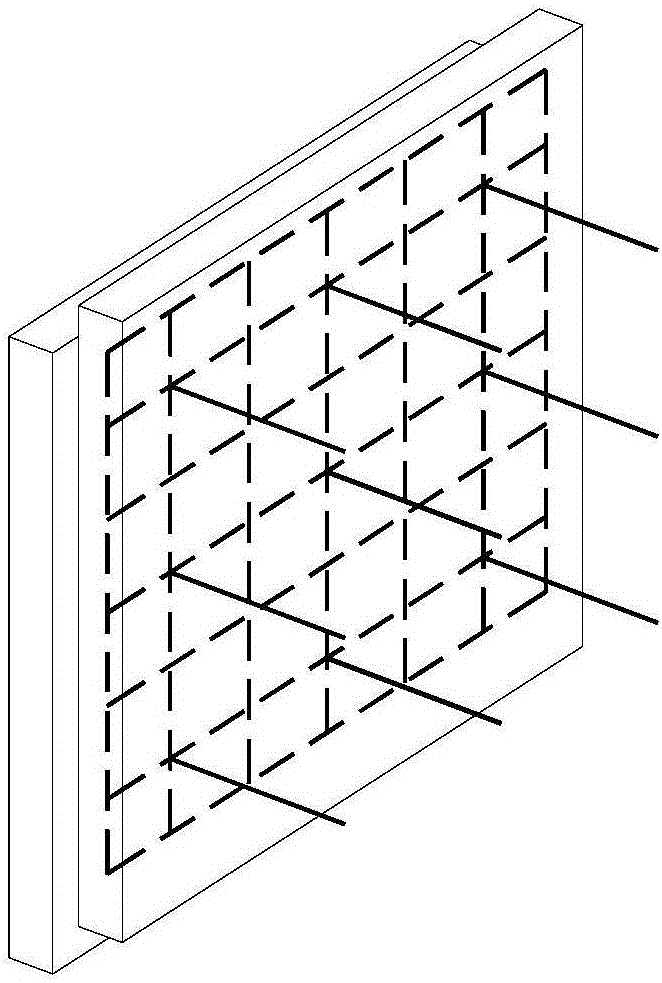

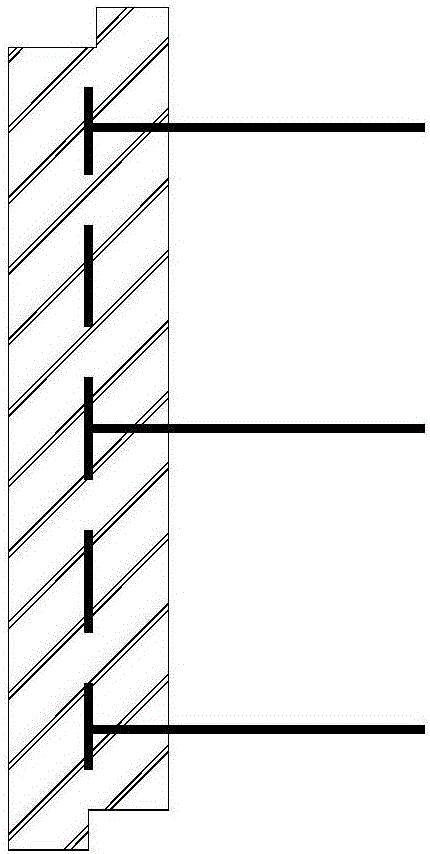

Method used

Image

Examples

Embodiment 1

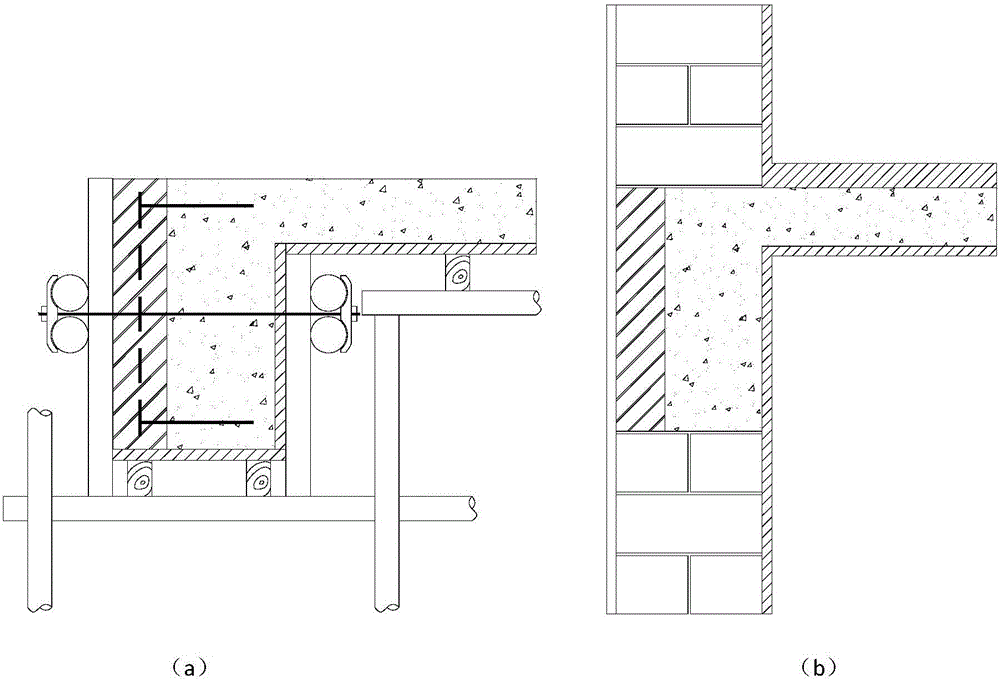

[0044] Embodiment 1: thermal insulation treatment at concrete beams, building structure such as image 3 As shown in (b), at the concrete beam, the construction method from indoor to outdoor is as follows: interior surface layer, concrete layer, insulation board with reinforcement, and external surface layer. The exterior surface layer can be divided into three types: paint, brick and stone. For heavy materials such as stone, it is necessary to leave embedded parts in the reinforced insulation board in advance. The masonry on the beam can use self-insulation wall combined with exterior finish layer, or ordinary masonry structure + insulation layer + exterior finish layer. It is recommended to use the former method first, because the construction of self-insulation wall is convenient, economical and durable ,Energy saving and environmental protection. Refer to the specific implementation steps image 3 (a) In order: erect scaffolding, set up concrete beam inner formwork and b...

Embodiment 2

[0045] Embodiment 2: thermal insulation treatment at the concrete shear wall of the exterior wall, the building structure is as follows Figure 4 As shown in (b), the construction methods from indoor to outdoor are as follows: interior surface layer, concrete layer, insulation board with reinforcement, and exterior surface layer. The interior and exterior finishes are the same as those of the concrete beams. Refer to the specific implementation steps Figure 4 (a) In order: bind the inner reinforcement of the concrete, set up the scaffolding of the concrete wall, set up the inner formwork, set up the outer scaffolding and wooden spacers, fix the reinforced insulation board as the outer formwork on the wooden spacer, and horizontally sew the insulation board The tongue and groove connection is adopted between the vertical seam and the vertical seam. For concrete shear walls, a tension screw is required between the reinforced insulation board and the inner formwork, and the te...

Embodiment 3

[0046] Embodiment 3: The thermal insulation structure when the exterior wall of the building is a balcony is as follows Figure 5 As shown in (b), in order to avoid generating cold and heat bridges, it is necessary to do all-round insulation treatment around the balcony slab, and the insulation panels on the bottom and sides of the balcony slab adopt the insulation panel with reinforcement of the present invention and double as the bottom form when pouring concrete And side formwork, the insulation board above the balcony slab can be without reinforcement, and other methods can also be used for insulation construction. Refer to the specific implementation steps Figure 5 (a) The order is as follows: scaffolding is erected, wooden formwork is laid on the indoor part, and thermal insulation boards with reinforcement are laid on the outdoor part that needs heat preservation as the bottom form and side form. The joints between the bottom forms can be connected by straight seams, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com