Antibacterial fabric and preparation method thereof

A kind of antibacterial fabric and fabric technology, applied in the direction of textiles, papermaking, fiber treatment, etc., can solve the problems of microbial resistance, poor binding force, poor heat resistance, etc., and achieve short-term and long-term antibacterial performance and cost Low, effective formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

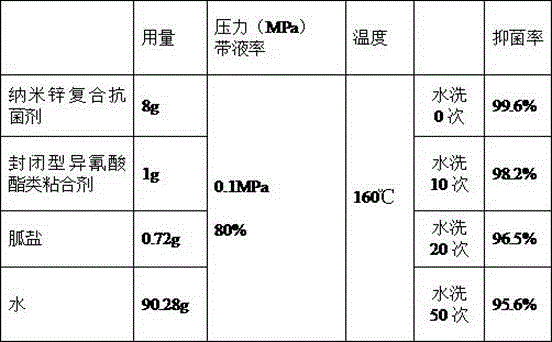

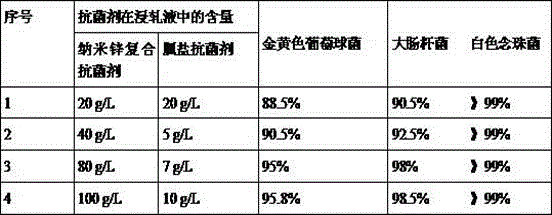

[0056] The padding liquid preparation process is as follows:

[0057] Weigh 0.72g guanidinium salt and dissolve it in 64.8g water to form A solution;

[0058] Weigh 8g of nano-zinc composite antibacterial agent, add it into solution A while stirring, stir for 5 minutes to mix evenly, and form solution B;

[0059] Weigh 1g of blocked isocyanate adhesive, add it into solution B while stirring, stir for 5min until mixed evenly, and form solution C;

[0060] Add 25.48g of water, mix well and prepare padding solution.

[0061] The preparation process of antibacterial fabric is as follows:

[0062] Inject the padding solution into the padding car working tank of the padding machine, then put the fabric into the padding car working tank, adjust the padding car pressure at 0.1MPa, and carry out the fabric padding process; the fabric liquid rate after padding treatment is 80%;

[0063] The padded fabric is dried at a temperature of 160° C. to obtain an antibacterial fabric.

[006...

Embodiment 2

[0067] The padding liquid preparation process is as follows:

[0068] Weigh 1 g of guanidinium salt and dissolve it in 90 g of water to form A solution;

[0069] Weigh 10g of nano-zinc composite antibacterial agent, add it into solution A while stirring, and stir for 8 minutes to mix evenly to form solution B;

[0070] Weigh 3g of blocked isocyanate adhesive, add it into solution B while stirring, stir for 7 minutes until the mixture is uniform, and form solution C;

[0071] Add 10g of water, mix well and prepare padding solution.

[0072] The preparation process of antibacterial fabric is as follows:

[0073] Inject the padding liquid into the padding car working tank of the padding machine, then put the fabric into the padding car working tank, adjust the padding car pressure at 0.3MPa, and carry out the fabric padding process; the fabric liquid rate after padding is 100%;

[0074] The padded fabric is dried at a temperature of 140° C. to obtain an antibacterial fabric. ...

Embodiment 3

[0076] The padding liquid preparation process is as follows:

[0077] Weigh 0.9 g of guanidinium salt and dissolve it in 75 g of water to form A solution;

[0078] Weigh 9.2g of nano-zinc composite antibacterial agent, add it into solution A while stirring, stir for 7.5min until mixed evenly, and form solution B;

[0079] Weigh 2.3g of blocked isocyanate adhesive, add it into solution B while stirring, stir for 8 minutes until the mixture is uniform, and form solution C;

[0080] Add 25g of water, mix well and prepare padding solution.

[0081] The preparation process of antibacterial fabric is as follows:

[0082] Inject the padding solution into the padding car working tank of the padding machine, then put the fabric into the padding car working tank, adjust the padding car pressure at 0.25MPa, and carry out the fabric padding process; the fabric liquid rate after the padding treatment is 90%;

[0083] The padded fabric is subjected to drying treatment at a drying temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com