Lactobacillus paracasei n1115 freeze-dried powder starter and preparation method thereof

A technology of Lactobacillus paracasei and paracasei, which is applied to the preparation of the Lactobacillus paracasei N1115 freeze-dried powder starter, freeze-drying protective agent, and the field of Lactobacillus paracasei N1115 freeze-dried powder starter, can solve the problem that the protection effect cannot be achieved, Low yield of viable bacteria, microbial cell damage and other problems, to achieve the effect of antifreeze protection, treatment of irritable bowel syndrome, and growth promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

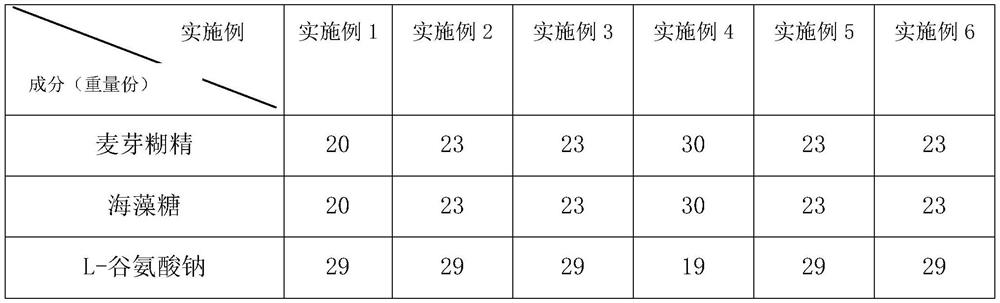

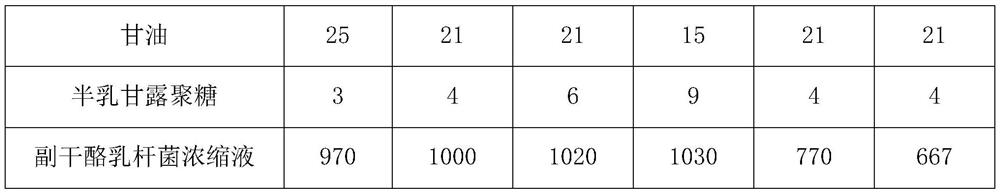

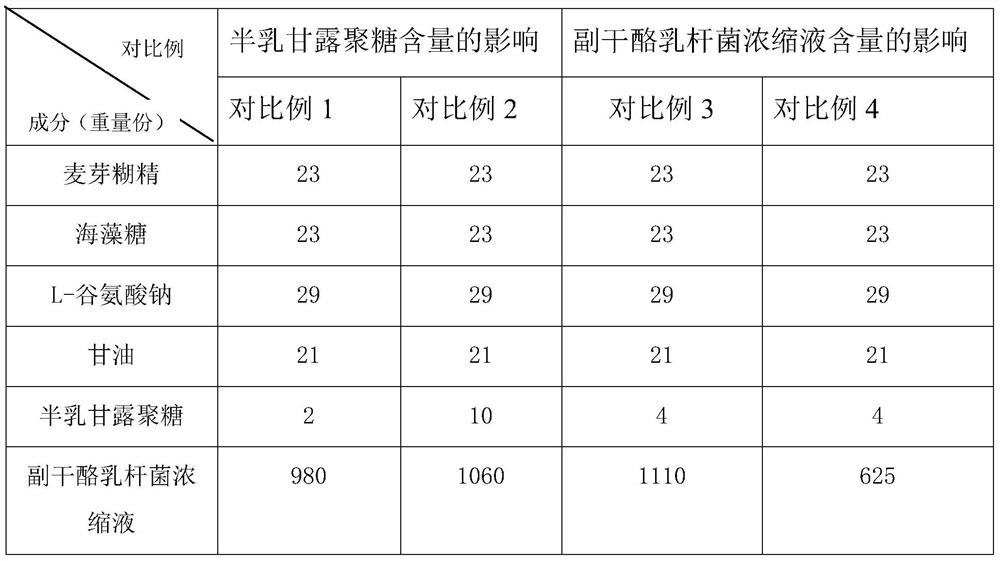

[0031] Embodiment 1-6 has shown the raw material composition of lyoprotectant, and under the raw material composition based on this lyoprotectant, combine the content of Lactobacillus paracasei concentrate to form Lactobacillus paracasei N1115 freeze-dried powder starter . It is shown in Table 1:

[0032] Table 1 Embodiment 1-6 raw material composition and content table

[0033]

[0034]

[0035] The preparation method of above-mentioned Lactobacillus paracasei N1115 freeze-dried powder starter comprises the following steps:

[0036] 1) Preparation of concentrated solution of Lactobacillus paracasei N1115: adjust the high-density culture solution of Lactobacillus paracasei N1115 after fermentation to pH 7.2, lower the temperature to 5°C, and perform low-temperature centrifugation at 8000r / min for 15min to obtain Lactobacillus paracasei N1115 Concentrate;

[0037] 2) Preparation of the mixed solution: the freeze-drying protective agent was sterilized at 121° C. for 15 ...

Embodiment 7

[0053] This example relates to the preparation method of Lactobacillus paracasei N1115 freeze-dried powder starter. In this example, different enrichment conditions are mainly selected in the preparation step of Lactobacillus paracasei N1115 concentrate. details as follows:

[0054] Adjust the high-density culture fluid of Lactobacillus paracasei N1115 that fermentation terminates to pH 7.2, adopt low-temperature high-speed centrifugation (5 ℃, 8000r / min), low-temperature low-speed centrifugation (5 ℃, 4000r / min), normal temperature high-speed centrifugation (25 ℃, 8000r / min) and room temperature low-speed centrifugation (25℃, 4000r / min) 4 different enrichment conditions, centrifuged for 15min, to obtain Lactobacillus paracasei N1115 concentrate.

[0055] Taking the bacterial cell survival rate and the concentration multiple in the Lactobacillus paracasei N1115 concentrated solution as detection items, the following parallel experiments were carried out, and n=2 to get the ave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com