Device and method for producing marsh gas by vinegar residue solid and liquid split-phase anaerobic digestion

A technology of anaerobic digestion and solid-liquid phase separation, applied in biochemical equipment and methods, methods of supporting/immobilizing microorganisms, sterilization methods, etc. Solve problems such as crusting and floating of vinegar residues, and achieve the effects of improving heat utilization efficiency, improving capacity, and increasing damage degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

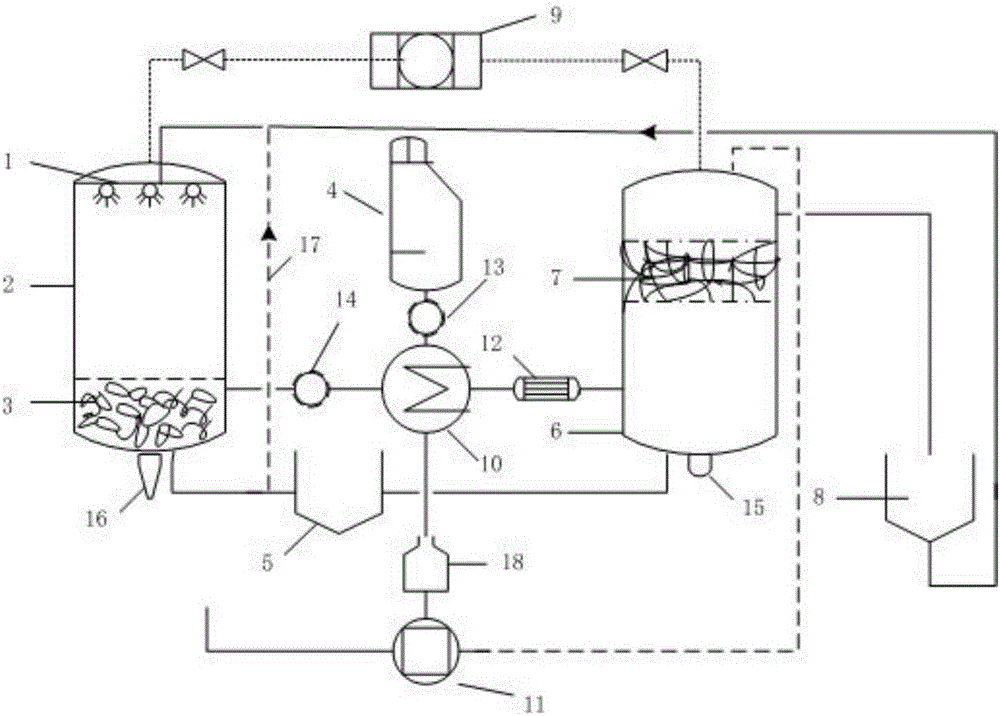

[0037] Such as figure 1 As shown, a device for producing biogas by solid-liquid phase separation anaerobic digestion of vinegar residues mainly includes a solid-state fermentation tank 2, a high-temperature digester 4, a packing reactor 6, a biogas purifier 9, a solid-liquid separator 11 and a storage tank 5, 8; the bottom end of the solid-state fermentation tank 2 is connected to one end of the reservoir A5, the upper end of the solid-state fermentation tank 2 is fixedly installed with a spray head 1, and the lower end is placed with a solid percolation bed 3; the other end of the reservoir A5 It is connected with the bottom of the packing reactor 6, and the position of the packing reactor 6 is equipped with a fibrous packing 7, and methanogenic bacteria are attached to the fibrous packing 7, and the liquid outlet at the upper end of the packing reactor 6 is connected to the reservoir B8, and the packing reactor 6 The liquid outlet at the upper end is located above the fiber ...

Embodiment 2

[0056] Experimental group: Using the washed vinegar grains after high-temperature hydrothermal treatment and washing liquid as raw materials, a 25L solid-state fermenter 2 and a 25L packed reactor 6 were used for solid-liquid phase separation anaerobic fermentation. Add the pre-acclimated biogas fermentation inoculum and keep it stable for one week. After the gas production of the system inoculum is basically zero, feed according to the organic load of 1.0gVS / L.d and 1.0g COD / L.d respectively. The initial pH values in the solid-state fermenter 2 and the packing reactor 6 were determined to be in the range of 6.5 to 8, and within 30 days of the first load operation, the methane content was in the range of 55% to 65%, and the pH value was stable at 6.5 to 8 within range.

[0057] In the second stage of fermentation load, that is, during the 31st to 60th day of operation, the organic load of 2.0g VS / L.d and 2.0g COD / L.d was fed, the methane content was in the range of 55% t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com