Up-draft type water vapor gasification device for biomass and tar mixture

A gasification device and water vapor technology, which is applied to the feeding tools of the gasification device, the gasification process, and the fixed bed gasification, etc. problem, to achieve the effect of reducing heavy tar content, reducing sensible heat loss, and avoiding energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

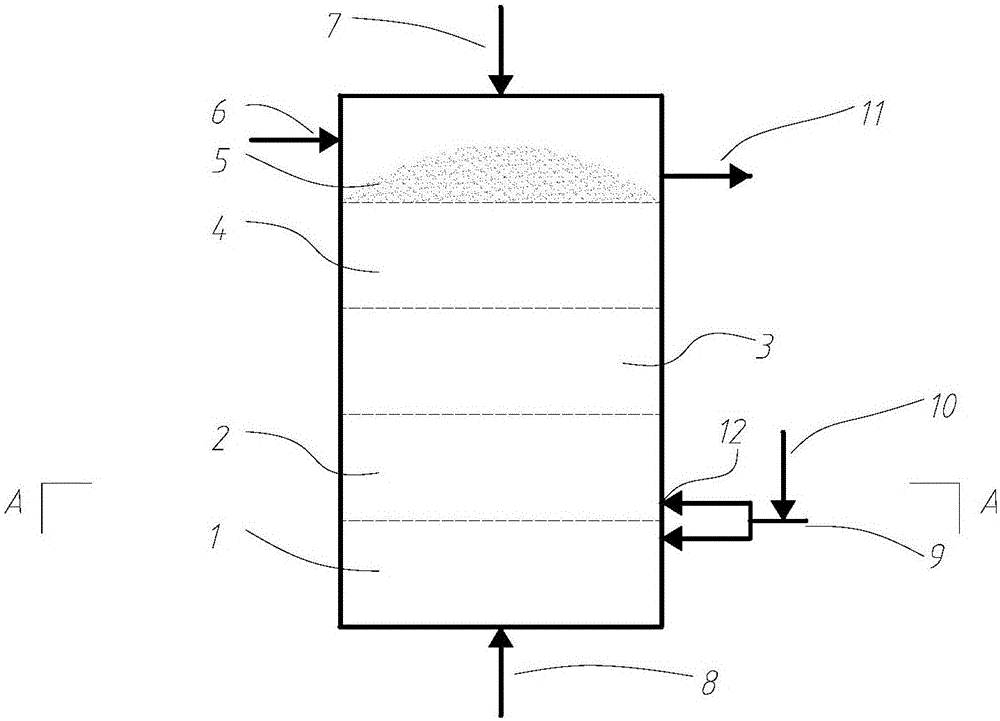

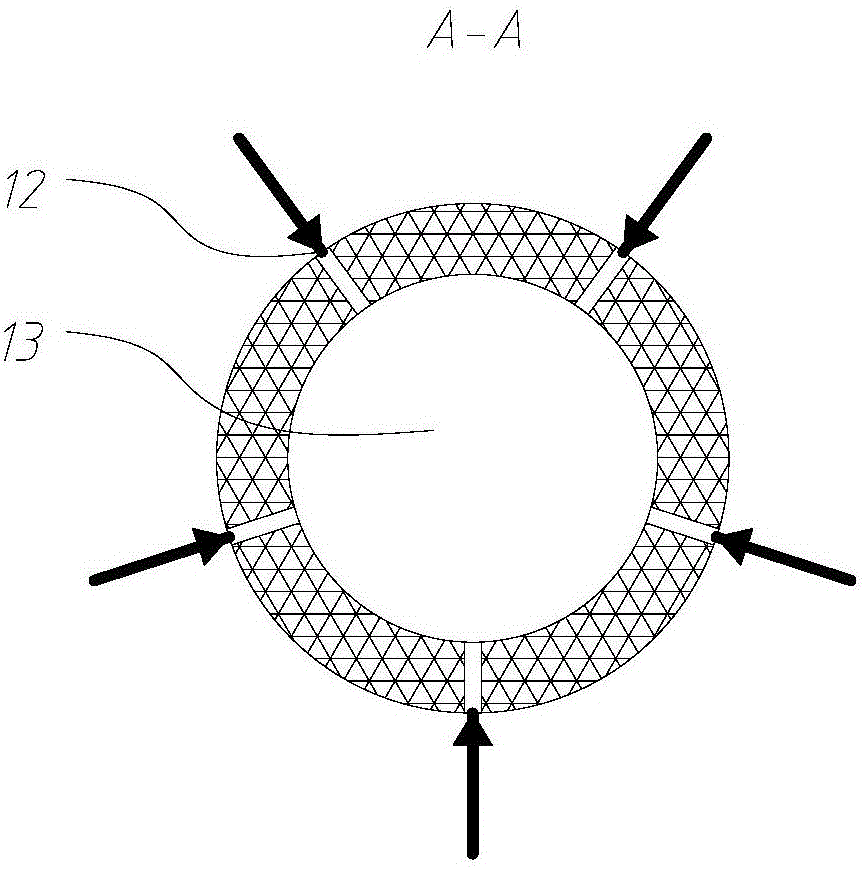

[0031] Such as figure 1 Shown is an up-suction steam gasification device for biomass and tar mixture with a biomass processing capacity of 1.5t / h. The device includes an up-suction gasification furnace, the main body is a cylindrical refractory masonry hearth 13 and a steel furnace shell, the lower part of the furnace shell is provided with a rotating grate connected by a dynamic seal, the rotating grate has both the function of air intake and distribution; the upward suction gasifier is divided into an oxide layer from bottom to top 1. The reduction layer 2, the pyrolysis layer 3, the drying layer 4 and the mixing zone 5; the upper part of the upper suction gasifier is provided with a gas outlet 11 and a feed inlet 6, and the top is provided with 1-3 emulsified tars The water injection inlet 7 is provided with an air interface 8 at the bottom of the oxide layer; the gas outlet 11 is connected with an indirect cooler to separate the tar from the gas and obtain the upper layer of...

Embodiment 2

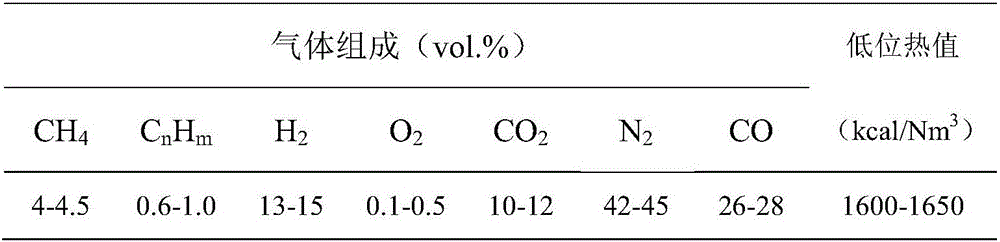

[0037] The device refers to example 1, the operating load is 1t / h, and the air input is 1000Nm 3 / h, the spraying amount of the heavy tar aqueous solution on the top is 200kg / h, the concentration of the heavy tar aqueous solution is 50wt.%, the saturated steam input at the bottom is about 50~80kg / h, and the light tar-containing water atomization interface 10 is open, the bottom contains light tar atomized water input of 20kg / h, of which the tar concentration is 15wt.%. Under this condition, the emulsified heavy tar water is mixed with biomass raw materials in the upper mixing zone of the up-suction gasifier. When the drying layer encounters the rising hot air flow below, it removes moisture and cools part of the tar in the air flow. Interception; the raw material that has been dewatered moves down to the pyrolysis layer to further pyrolyze into volatile matter and solid coke, and the volatile matter is carried upward by the airflow; the solid coke sequentially enters the reducin...

Embodiment 3

[0039] The device refers to Example 1, the difference is that the biomass processing capacity is 2t / h, the top of the device is equipped with 4 emulsified tar water injection ports 7, and the boundary between the oxide layer 1 and the reduction layer 2 is provided with 4 A common nozzle interface 12.

[0040] The operating load is 2t / h, the top of which contains heavy tar aqueous solution, the injection rate is 300~500kg / h, and the bottom of the air through the air interface 8 is 2000Nm 3 / h, the saturated water vapor input at the bottom through the pressurized water vapor interface 9 is 650kg / h, the saturated water vapor parameter is 0.25-0.4MPa, 127-143°C, and the bottom through the light tar atomized water interface 10 The input amount of atomized water containing light tar is 100kg / h, of which the tar content is 50-100g / L. Under these operating conditions, the residence time of the heavy tar aqueous solution and the biomass raw material in the upper mixing zone 5 of the updra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com