Solid nanometer particle-thickened paraffin aggregate and preparation method thereof

A nano-aggregate technology, which is applied in the field of wax aggregates thickened by solid nano-particles and its preparation, can solve the problems of wax flowing and melting at high temperature, and achieve the effect of solving high-temperature flowing and melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

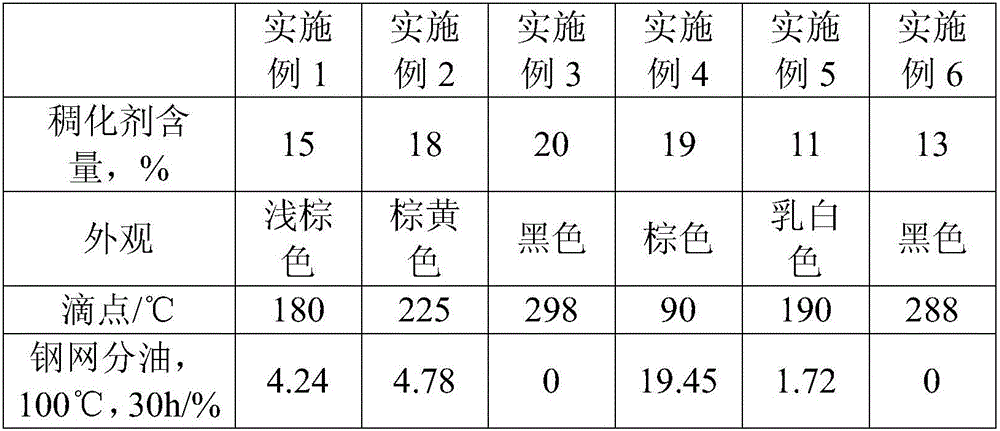

Embodiment 1

[0021] Heat 88.0g of 50# paraffin and 5.5g of diphenylsilanediol to 100°C, stir for 10 minutes to dissolve completely to obtain a paraffin system. Under the condition of high-speed stirring (500 rpm), 16.5g of nano-silicon nitride was added to the paraffin wax system, and the reaction was continued at 100°C for 10 minutes to make the stirring even, then the temperature was raised to 200°C, and the reaction was 2.5h. Add 0.5g of polymethacrylate at 100°C, stir evenly, let stand and cool to room temperature to obtain the product.

Embodiment 2

[0023] Heat 41.0g of 50# paraffin and 41.0g of base oil to 80°C, stir for 20 minutes to dissolve completely to obtain a paraffin system. Add 18.0g of nano-silicon nitride into the paraffin wax system under high-speed stirring conditions (600 rpm), continue to stir and react at 80°C for 15 minutes to make the stirring even, then raise the temperature to 190°C, react for 2 hours, stop heating, and let it stand for cooling The product was obtained at room temperature.

Embodiment 3

[0025] Heat 88.0g of 50# paraffin and 5.0g of diphenylsilanediol to 100°C, stir for 10 minutes to dissolve completely to obtain a paraffin system. Under high-speed stirring conditions (500 rpm), 16.5g of nano-silicon nitride was added to the paraffin wax system, and the reaction was continued at 100°C for 10 minutes to make the stirring even, then the temperature was raised to 180°C, 5.5g of expanded graphite was added, and the reaction was continued at 180°C. Stir at ℃ for 10 minutes to make the stirring uniform, then raise the temperature to 195℃, react for 1.0h, stop heating, let stand and cool to room temperature to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com