Wear-resistant regenerated PC/POK alloy material and its preparation method and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

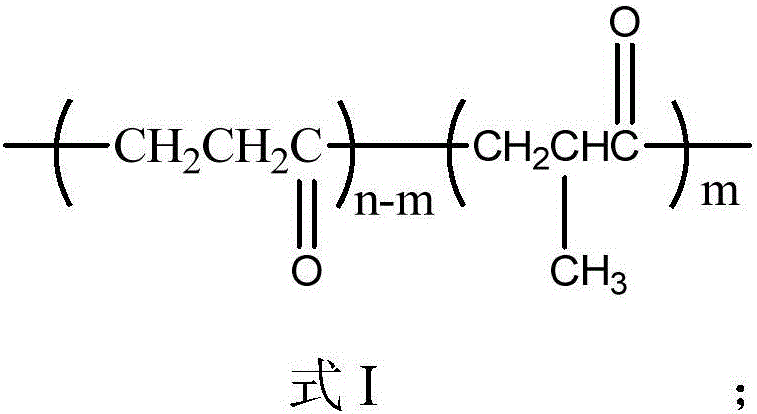

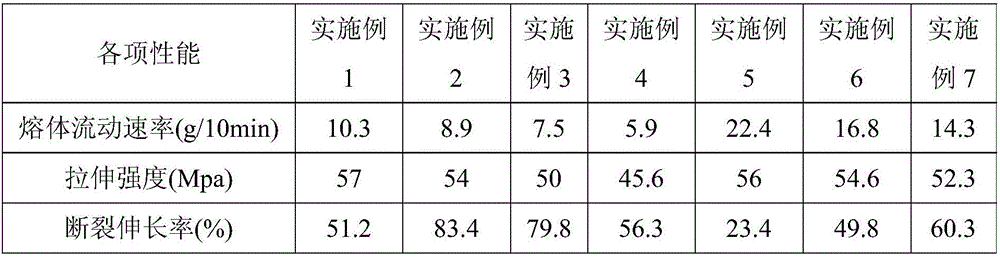

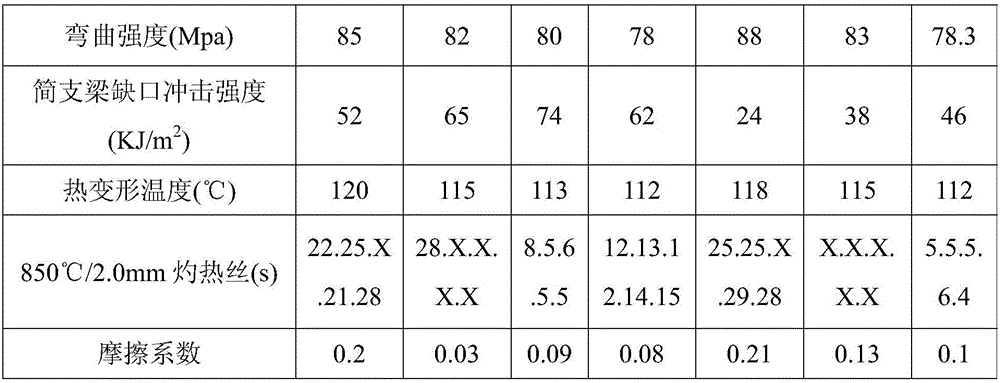

[0058] Embodiments 1 to 10 relate to a wear-resistant recycled PC / POK alloy material, and the content of each formula component of the material is shown in Table 1; wherein, the recycled PC-1 resin is made of recycled resin with MI in the range of 10-20. Pellets (granulated materials after crushing and blending, the weight percentage of impurities is less than or equal to 3%, and the melt flow rate is 10-20g / 10min under the condition of 300°C / 1.2kg), recycled PC-2 resin Select recycled resin pellets with MI in the range of 20-30 (the pellets after crushing and blending, the weight percentage of impurities is less than or equal to 3%, and the melt flow rate under the condition of 300 ° C / 1.2 kg is 20-30g / 10min); polyketone POK uses medium flow M330A (Korean HYOSUNG company), and its MI is 60g / 10min (240℃ / 2.16KG); g-MAH series CMG9804 compatibilizer; the flame retardant is BC58 (brominated polycarbonate flame retardant, 2,4,6-tribromophenoxy-terminated tetrabromobisphenol A ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com