Fluorine titanium hybrid flame retardant, and preparation method and application thereof

A flame retardant and curing agent technology, applied in the direction of titanium organic compounds, etc., can solve the problems of harsh reaction conditions and complex formulations, and achieve the effects of simple and mild reaction conditions, simple product purification operations, and high yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

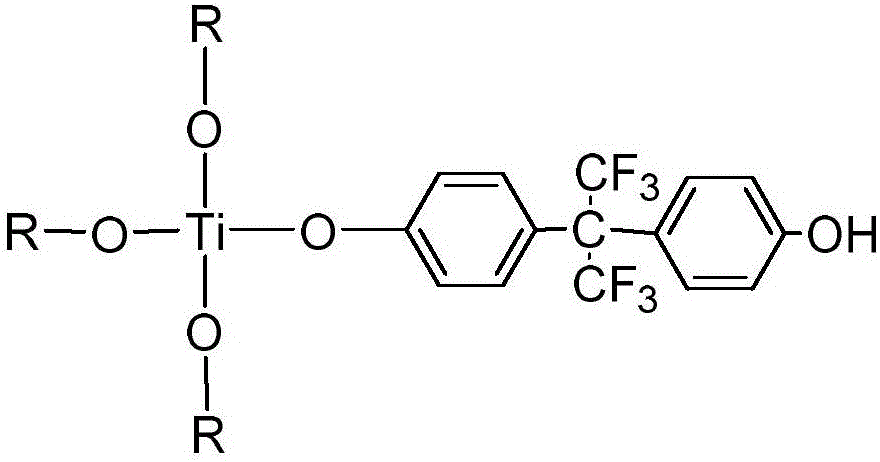

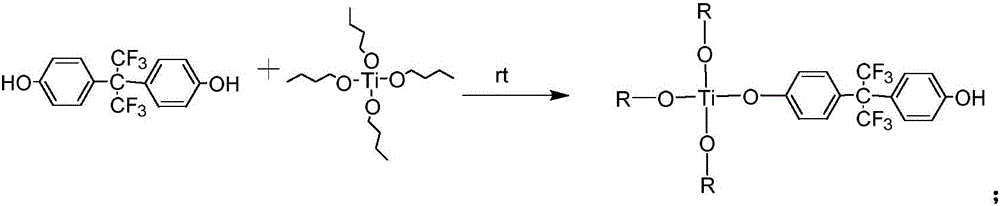

[0027] Add 0.336g (0.001mol) of hexafluorobisphenol A and 20mL of ethanol into a 50mL three-necked round-bottomed flask, and then dissolve 0.085g (0.00025mol) of butyl titanate in 3mL of ethanol, and dissolve evenly. The mixture was added dropwise into the above-mentioned three-necked flask, and the reaction was stirred at room temperature for 24 h. After the reaction was completed, the solvent was removed by rotary evaporation to obtain a crude product, which was washed with ethanol three times and freeze-dried to obtain a fluorine-titanium hybrid flame retardant with a yield of about 96%.

[0028] The infrared spectrogram of the fluorine-titanium hybrid flame retardant is shown in figure 1 shown. 994cm -1 The spectrum peak is -Ti-O-C 6 h 4 - The characteristic absorption peak of the group.

Embodiment 2

[0030] Preparation of pure epoxy resin

[0031] Pure epoxy resin was used as the control group. Weighed 20g of epoxy resin E-51, raised the temperature to 90°C, added 5g of curing agent 4,4'-diaminodiphenylmethane, stirred evenly, poured into the mold, and kept at 120°C 5h, then at 140°C for 2h, and finally at 180°C for 2h.

[0032] The oxygen index of the prepared flame-retardant epoxy resin was tested according to the GB / T 2406.2-2009 method to be 25.4%.

[0033] The prepared flame retardant epoxy resin was tested according to the GB / T 2408-2008 method and the results of its vertical burning rating are shown in Table 1.

Embodiment 3

[0035] Weigh 20g of epoxy resin E-51, raise the temperature to 100°C, add 0.25g of the fluorine-titanium hybrid flame retardant prepared in Example 1, the added mass of the flame retardant is calculated according to the mass percentage, the fluorine-titanium hybrid flame retardant is 1% of epoxy resin, while stirring, use vacuum to remove small molecular substances, add 5g of 4,4'-diaminodiphenylmethane after completely dissolving, pour into the mold after stirring, keep at 120°C for 5h, and then Insulate at 140°C for 2 hours, and finally at 180°C for 2 hours, flame retardant epoxy resin.

[0036] The oxygen index of the prepared flame-retardant epoxy resin was tested according to the GB / T 2406.2-2009 method to be 28.9%.

[0037] The prepared flame retardant epoxy resin was tested according to the GB / T 2408-2008 method and the results of its vertical burning rating are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com