Thermotropic liquid crystal polyester with stable monomer composition ratio and its preparation method and application

A liquid crystal polyester and thermotropic technology, which is applied in the field of liquid crystal polyester, can solve the problems of large performance differences, unstable structure of liquid crystal polyester products, and the inability of monomers or oligomers to return to the reaction system, etc. The loss of body and the effect of stabilizing the ratio of monomer composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

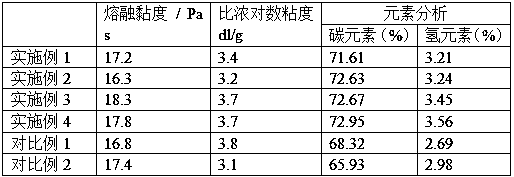

Examples

Embodiment 1

[0049] Add the following monomer raw materials, acylating agent, and catalyst to a reaction vessel equipped with a stirrer, a monomer feeding port, a reflux condenser, a thermometer, a nitrogen gas inlet, and a torque sensor.

[0050] 4-Hydroxybenzoic acid (HBA) 10.08kg (73mmol),

[0051] 6-Hydroxy-2-naphthoic acid (HNA) 5.08kg (27mmol),

[0052] Catalyst: Magnesium acetate 150 mg,

[0053]After the feeding was completed, the atmosphere in the reaction vessel was completely replaced with nitrogen, and the temperature of the reaction system was raised to 120°C under the protection of nitrogen, and the acetylation reaction was carried out at this temperature for 3 hours under reflux. After the acetylation reaction is over, increase the nitrogen pressure, keep the pressure of the reaction system at 1.5MPa and raise the temperature to 270°C, and release the pressure to normal pressure after continuing the reaction for 1 hour, and discharge the acetic acid and unreacted acetic anh...

Embodiment 2

[0057] Add the following monomer raw materials, acylating agent, and catalyst to a reaction vessel equipped with a stirrer, a monomer feeding port, a reflux condenser, a thermometer, a nitrogen gas inlet, and a torque sensor.

[0058] 4-Hydroxybenzoic acid (HBA) 10.08kg (73mmol),

[0059] 6-Hydroxy-2-naphthoic acid (HNA) 5.08kg (27mmol),

[0060] Catalyst: Magnesium acetate 150 mg,

[0061] After the feeding was completed, the atmosphere in the reaction vessel was completely replaced with nitrogen, and the temperature of the reaction system was raised to 120°C under the protection of nitrogen, and the acetylation reaction was carried out at this temperature for 3 hours under reflux. After the acetylation reaction is over, increase the nitrogen pressure, keep the pressure of the reaction system at 1.5 MPa and raise the temperature to 280°C, and release the pressure to normal pressure after continuing the reaction for 1 hour, and discharge the acetic acid and unreacted acetic a...

Embodiment 3

[0065] Add the following monomer raw materials, acylating agent, and catalyst to a reaction vessel equipped with a stirrer, a monomer feeding port, a reflux condenser, a thermometer, a nitrogen gas inlet, and a torque sensor.

[0066] 4-Hydroxybenzoic acid (HBA) 10.08kg (73mmol),

[0067] 6-Hydroxy-2-naphthoic acid (HNA) 5.08kg (27mmol),

[0068] Catalyst: Magnesium acetate 150 mg,

[0069] After the feeding was completed, the atmosphere in the reaction vessel was completely replaced with nitrogen, and the temperature of the reaction system was raised to 120°C under the protection of nitrogen, and the acetylation reaction was carried out at this temperature for 3 hours under reflux. After the acetylation reaction is over, increase the nitrogen pressure, keep the pressure of the reaction system at 1.5MPa and raise the temperature to 290°C, and release the pressure to normal pressure after continuing the reaction for 1 hour, and discharge the acetic acid and unreacted acetic an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com