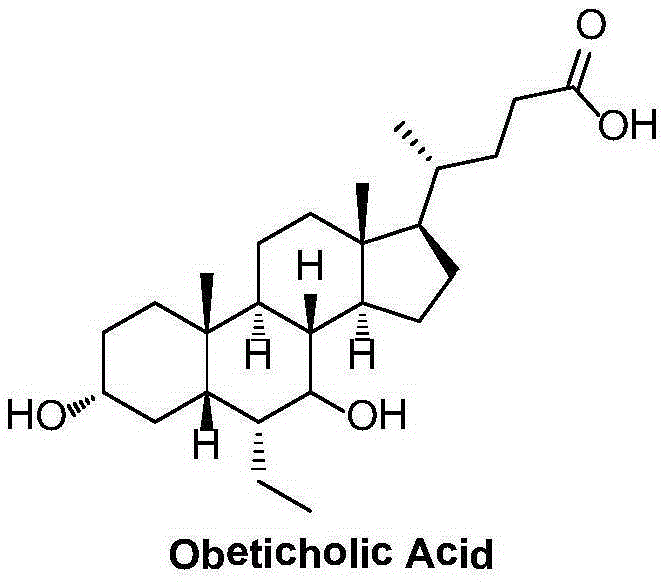

Preparation method of high-purity obeticholic acid

A high-purity obeticholic acid technology, applied in the field of preparation of obeticholic acid, can solve the problems of increased impurity chenodeoxycholic acid, low configuration selectivity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

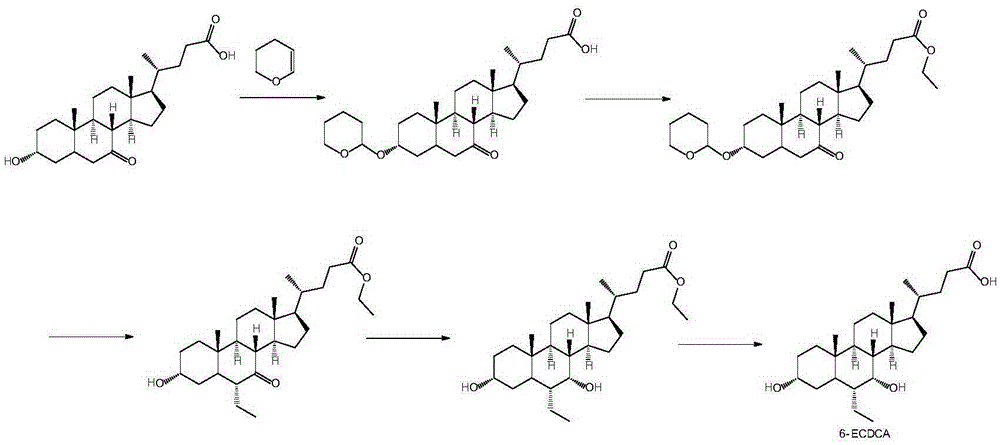

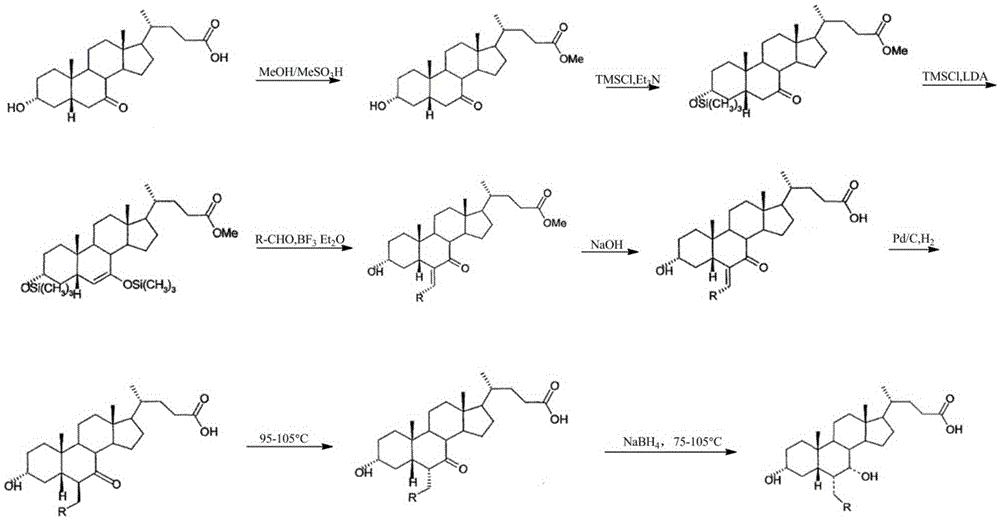

Method used

Image

Examples

Embodiment 1a

[0051] Example 1a Preparation of 3α-hydroxyl-7-keto-5β-cholanic acid (III)

[0052]

[0053] Add chenodeoxycholic acid (II) (113g, 0.288mol), sodium bromide (1.78g, 0.0173mol), acetic acid (30mL) and methanol (600mL) successively to the reaction flask, stir at room temperature until all dissolve, and cool to -10°C±2°C, slowly add 13% sodium hypochlorite solution (225mL, 0.39mol) dropwise to the reaction system, control the internal temperature at -10~0°C and stir the reaction until the content of chenodeoxycholic acid (II) is detected by HPLC less than 1%. After the reaction was completed, the ice bath was removed, and the reaction solution naturally rose to room temperature, and 5% sodium bisulfite solution (25 mL) was added dropwise to the reaction system, stirred for 30 minutes, suction filtered, and dried to obtain 3α-hydroxy-7-keto - Crude 5β-cholanic acid (III) (115.83 g). Add the crude product and methanol (1L) into the reaction flask, heat to 65°C, reflux for half...

Embodiment 1b

[0054] Example 1b Preparation of 3α-hydroxyl-7-keto-5β-cholanic acid (III)

[0055]

[0056] Add chenodeoxycholic acid (II) (100g, 0.255mol), anhydrous magnesium sulfate (200g), chloroform (300mL) to the reaction flask in turn, stir at room temperature, and add pyridinium chlorochromate dichloride dropwise to the reaction system Methane solution (61 g of pyridinium chlorochromate dissolved in 2.5 L of dichloromethane), and the reaction solution was stirred at room temperature for 30 min. The solid insoluble matter was filtered, the filtrate was washed with water and saturated brine successively, the organic phase was dried over anhydrous sodium sulfate, and concentrated under reduced pressure to obtain 3α-hydroxy-7-keto-5β-cholanic acid (III) (73g, yield 73.3 %, HPLC detection: 97.7%).

Embodiment 2a

[0057] Example 2a Preparation of 3α-hydroxyl-7-keto-5β-cholanoic acid methyl ester (IVa)

[0058]

[0059] 3α-Hydroxy-7-keto-5β-cholanic acid (III) (50 g) and methanol (360 mL) were sequentially added into the three-neck flask and stirred to dissolve. Cool to below 10°C, add thionyl chloride (14mL) dropwise, then heat to 65°C, and reflux for 3h. After the reaction is completed, cool to 5°C, and add H 2 O (360ml), natural cooling and crystallization, adding seed crystals, accelerated stirring. A large amount of solid precipitated out, stirred for 3 hours, filtered the product, and dried to obtain IVa (47.3 g, yield 91.3%) with a purity of 98.95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com