Multifunctional pesticide fertilizer and preparation method and application thereof

A multi-functional, medicated fertilizer technology, applied in the application, nitrogen fertilizer, potassium fertilizer and other directions, can solve the problems of not directly killing crop diseases and insect pests, increasing labor costs, and using pesticides in addition, to stimulate the microscopic biological activity of plants, reduce phytotoxicity, Enhanced resistance to stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

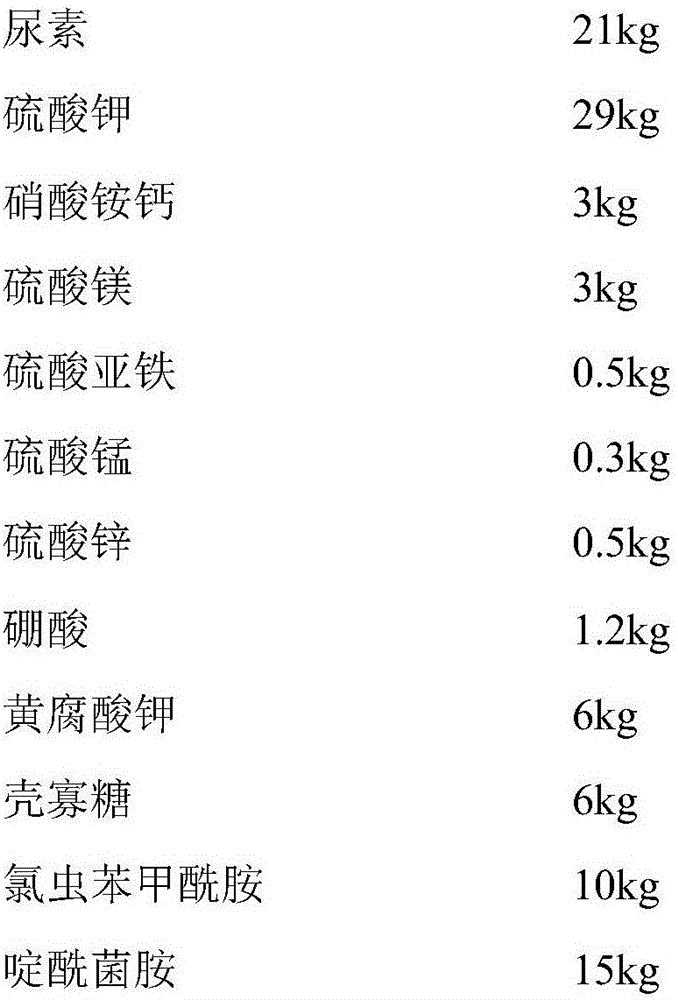

Embodiment 1

[0033]

[0034]

[0035] The preparation method is as follows:

[0036] (1) Accurately weigh the above raw materials for use;

[0037] (2) Crush 21 kg of urea and 29 kg of potassium sulfate to 80 mesh and mix them uniformly to obtain component A;

[0038] (3) Crush 3kg of calcium ammonium nitrate, 3kg of magnesium sulfate, 0.5kg of ferrous sulfate, 0.3kg of manganese sulfate, 0.5kg of zinc sulfate, and 1.2kg of boric acid to 80 meshes and mix them uniformly to obtain component B;

[0039] (4) Crush 6 kg of potassium fulvic acid and 6 kg of chitosan oligosaccharides to 80 meshes and mix them evenly to obtain component C;

[0040] (5) Weigh and mix 10 kg of chlorantraniliprole, 15 kg of boscalid, 3 kg of sodium butyl naphthalene sulfonate, and 1.5 kg of hydroxymethyl cellulose, and superfinely pulverize to 3000 mesh to obtain component D ;

[0041] (6) Mix components B, C and D uniformly to obtain component E;

[0042] (7) Mix components E and A uniformly to obtain the finished product.

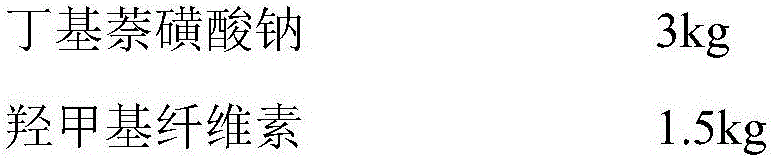

Embodiment 2

[0044]

[0045] The preparation method is as follows:

[0046] (1) Accurately weigh the above raw materials for use;

[0047] (2) Crush 15 kg of urea, 5 kg of monoammonium phosphate, and 25 kg of potassium sulfate to 60 meshes and mix them uniformly to obtain component A;

[0048] (3) Grind 5 kg of EDTA-calcium, 2 kg of EDTA-zinc, and 3 kg of boric acid to 100 meshes and mix them uniformly to obtain component B;

[0049] (4) Crush 5 kg of potassium fulvic acid and 3 kg of chitosan oligosaccharides to 60 mesh and mix them uniformly to obtain component C;

[0050] (5) Weigh and mix 5 kg of chlorantraniliprole, 25 kg of boscalid, 8 kg of fatty alcohol polyoxyethylene ether, and 4 kg of methyl cellulose, and perform ultrafine pulverization to 2500 mesh to obtain component D;

[0051] (6) Mix components B, C and D uniformly to obtain component E;

[0052] (7) Mix components E and A uniformly to obtain the finished product.

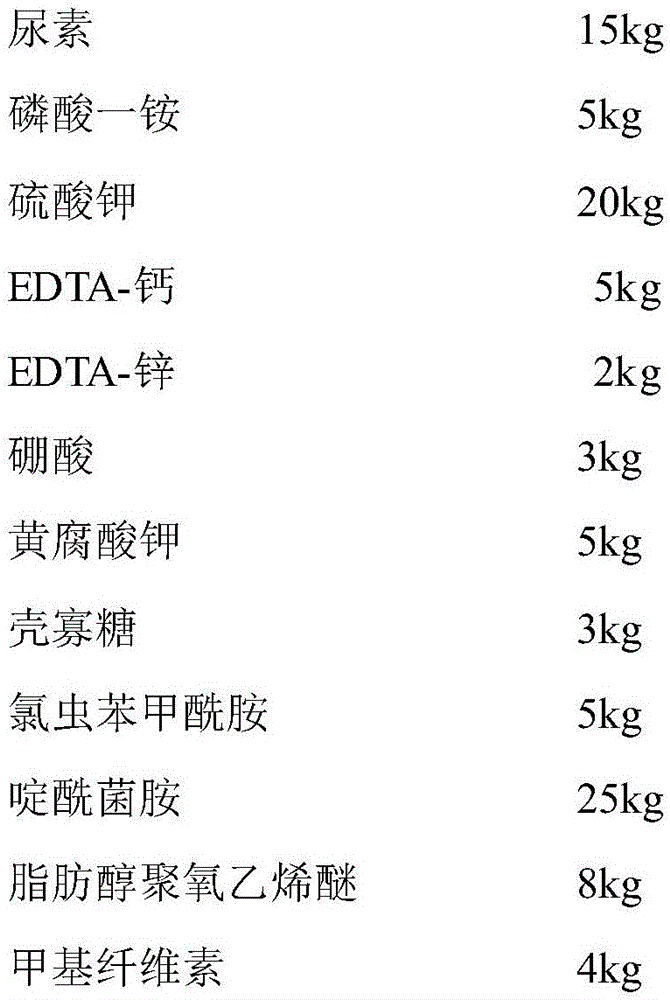

Embodiment 3

[0054]

[0055] The preparation method is as follows:

[0056] (1) Accurately weigh the above raw materials for use;

[0057] (2) Crush 30 kg of urea, 16 kg of monoammonium phosphate, and 29 kg of potassium sulfate to 100 meshes and mix them uniformly to obtain component A;

[0058] (3) Crush 1 kg of zinc sulfate and 1 kg of boric acid to 60 meshes and mix them uniformly to obtain component B;

[0059] (4) Crush 10 kg of potassium fulvic acid and 1 kg of chitosan oligosaccharides to 100 meshes and mix them uniformly to obtain component C;

[0060] (5) Weigh and mix 1 kg of chlorantraniliprole, 5 kg of boscalid, 5 kg of sodium butyl naphthalene sulfonate, and 1 kg of white carbon black, and perform ultrafine pulverization to 3500 mesh to obtain component D;

[0061] (6) Mix components B, C and D uniformly to obtain component E;

[0062] (7) Mix components E and A uniformly to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com