Sweet corn functional fertilizer

A sweet corn, functional technology, applied in the field of nutritional functional fertilizers, can solve the problems of incomplete grains, low sweetness, long bald tips, etc., and achieve the effects of improving quality, increasing resistance, and meeting nutrient requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Select raw materials by weight percentage: urea 32%, monoammonium phosphate 10%, ammonium sulfate 10%, potassium chloride 25%, chelated zinc 0.1%, borax 0.5%, nano synergist 0.5%, organic carbon 0.2%, add The granulation auxiliary material attapulgite powder is 21.7%, and then put into a granulator for granulation.

[0024] The NPK content in the above raw material components is 18%, 5% and 15% respectively, the total nutrient content is 38%, and the organic matter content of small molecule organic carbon is ≥ 95%.

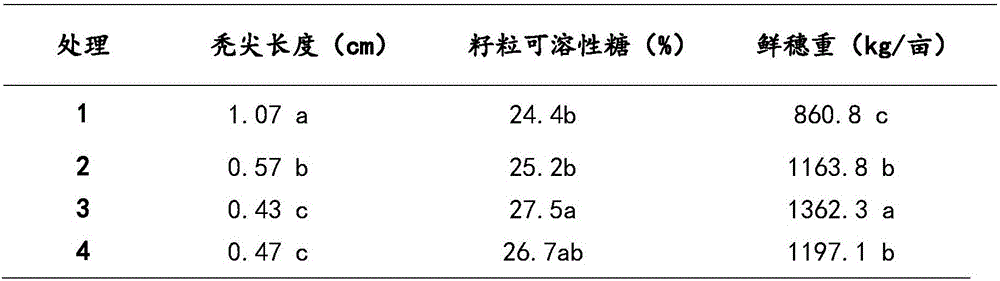

[0025] Comparative Test:

[0026] The test material is the functional fertilizer of this embodiment, and the reference formula (conventional) is the common compound fertilizer with NPK content of 18%, 5%, and 15% respectively. This test has 4 treatments altogether, and each process is repeated 3 times. Arranged, the area of the community is 30m 2 .

[0027] Each treatment design is as follows:

[0028] Treatment 1: blank control (no fertilization thro...

Embodiment 2

[0043] Select raw materials by weight percentage: urea 38%, monoammonium phosphate 10%, ammonium sulfate 10%, potassium chloride 25%, chelated zinc 0.2%, borax 1%, nano synergist 0.7%, organic carbon 0.5%, add The attapulgite powder 14.6% of the granulation auxiliary material is then put into a granulator for granulation.

[0044] The content of NPK in the above raw material components is 20%, 5% and 15%, respectively, the total nutrient content is 40%, and the organic matter content of small molecule organic carbon is ≥ 95%.

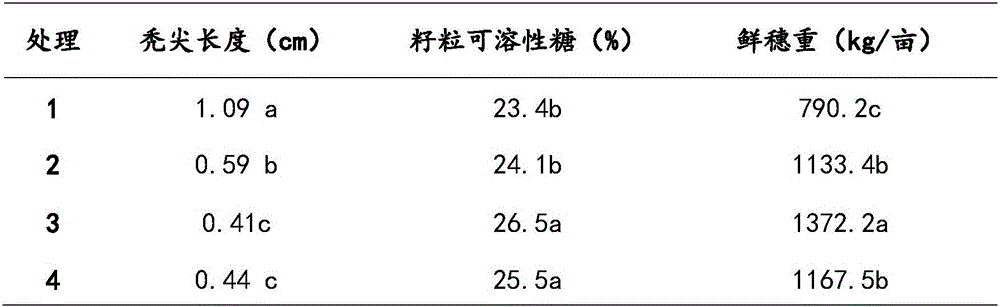

[0045] Comparative Test:

[0046] The test material is the functional fertilizer of this embodiment, and the reference formula (conventional) is a common compound fertilizer with NPK content of 20%, 5%, and 15% respectively. This test has 4 treatments altogether, and each treatment is repeated 3 times. Arranged, the area of the community is 30m 2 .

[0047] Each treatment design is as follows:

[0048] Treatment 1: blank control (no fertilization ...

Embodiment 3

[0063] Select raw materials by weight percentage: urea 38%, monoammonium phosphate 16%, ammonium sulfate 5%, potassium chloride 15%, chelated zinc 0.2%, borax 0.5%, nano synergist 0.7%, organic carbon 0.2%, add The granulation auxiliary material attapulgite powder is 24.4%, and then put into a granulator for granulation.

[0064] The NPK content in the above raw material components is 18%, 8%, and 15% respectively, the total nutrient content is 41%, and the small molecular organic carbon organic matter content is ≥ 96%.

[0065] Comparative Test:

[0066] The test material is the functional fertilizer of this embodiment, and the reference formula (conventional) is the common compound fertilizer with NPK content of 18%, 8%, and 15% respectively. This test has 4 treatments altogether, and each process is repeated 3 times. Arranged, the area of the community is 30m 2 .

[0067] Each treatment design is as follows:

[0068] Treatment 1: blank control (no fertilization throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com