Method for preparing high-performance composite carbon-fiber heat-insulating cylinder

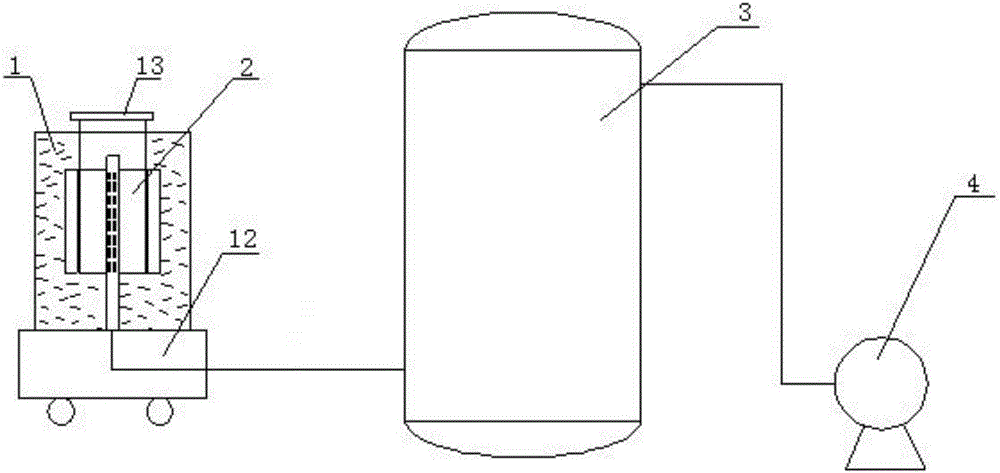

A technology of composite carbon fiber and a manufacturing method, which is applied in the field of making heat preservation cylinders for high-temperature furnaces, can solve the problems of low strength of carbon fiber hard felt, high binder content, poor oxidation resistance, etc. good support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] In the present embodiment, the manufacturing method of the high-performance composite carbon fiber insulation cylinder is as follows:

[0072] 1) Prepare chopped carbon fibers; chop the pitch-based carbon fibers to obtain chopped carbon fibers with an average length of 40 mm;

[0073] 2) preparing ground carbon fibers; grinding the pitch-based carbon fibers to obtain ground carbon fibers with an average length of 100 μm;

[0074] 3) using a cyclone separator to fully mix the chopped carbon fiber and the ground carbon fiber according to the weight ratio of 60:40 to obtain the mixed carbon fiber;

[0075] 4) Mix the mixed carbon fiber with the organic binder phenolic resin and solvent ethanol in a weight ratio of 100:30:70 to obtain a carbon fiber mixture; put the carbon fiber mixture into a mesh bag, pass through a mesh with a mesh size of 30 μm After the initial filtration of the bag, use hot air at 50°C to blow directly into the mesh bag for 30 minutes to completely v...

Embodiment 2

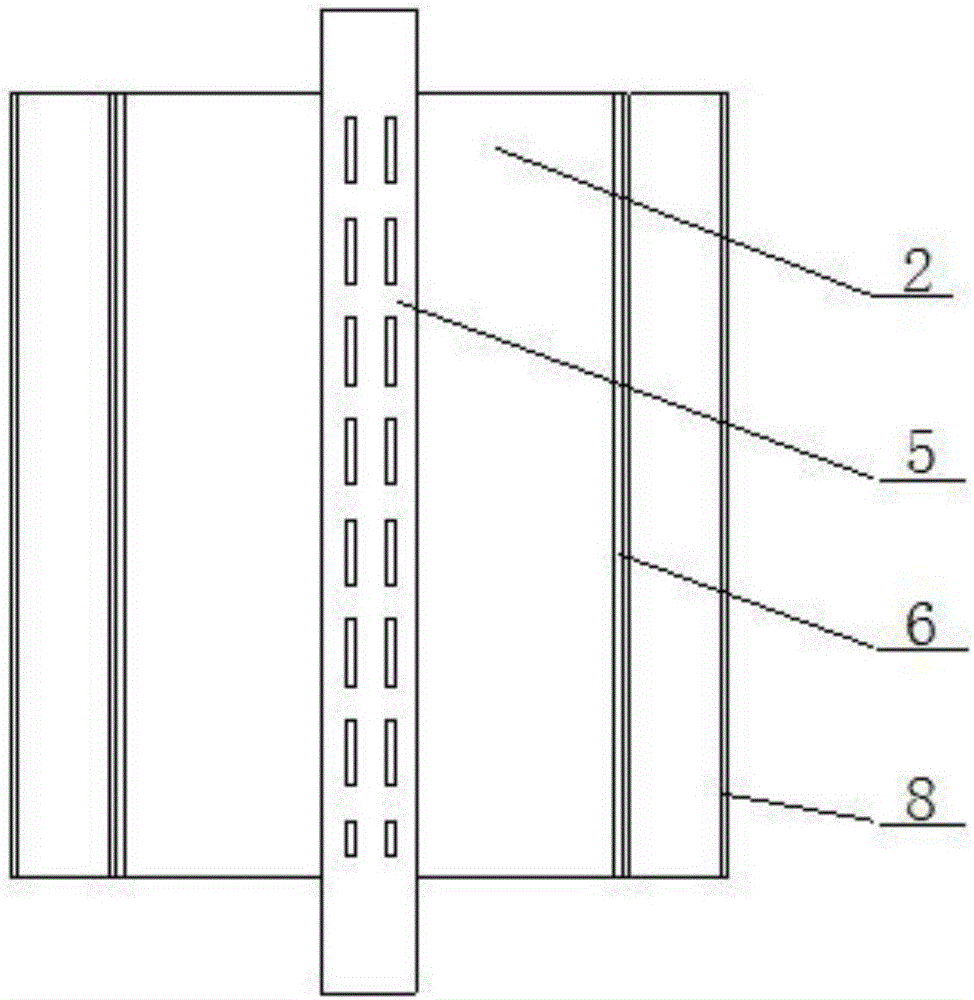

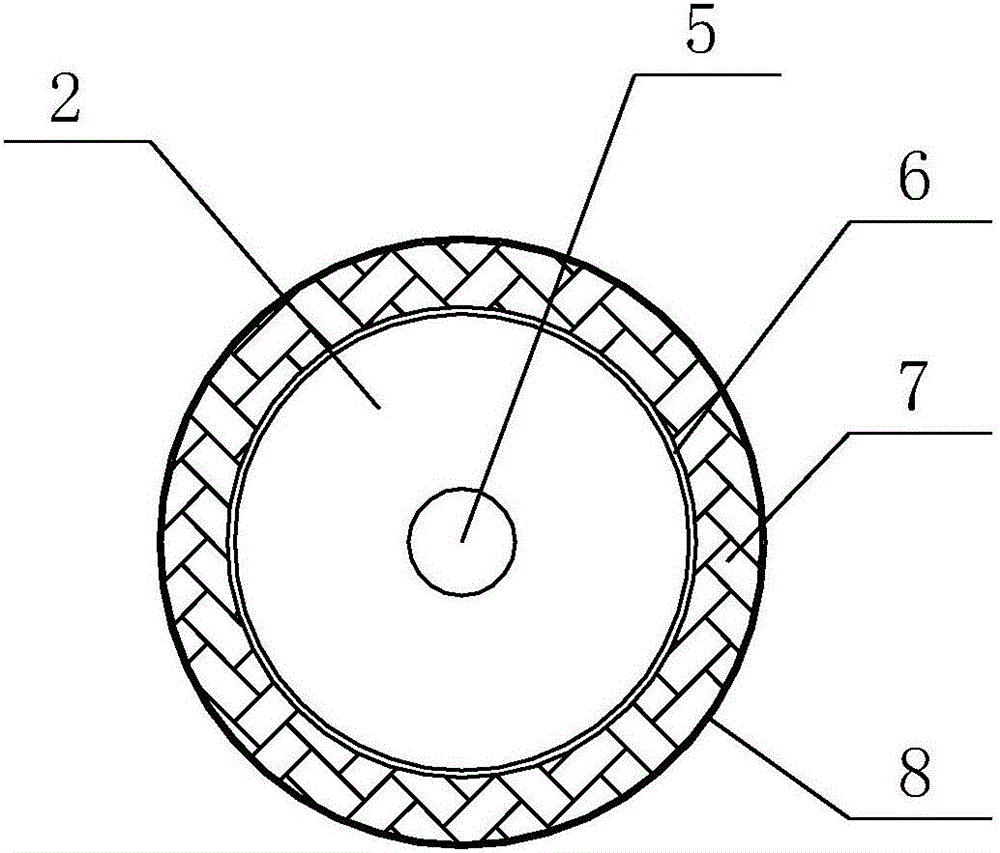

[0084] In order to increase the anti-airflow erosion and anti-oxidation performance of the composite carbon fiber insulation cylinder 9, and further improve its service life; the composite carbon fiber insulation cylinder 9 prepared in [Example 1] is subjected to surface treatment, and the specific steps of surface treatment are as follows:

[0085] 1) The composite carbon fiber insulation cylinder 9 is machined for surface polishing to make the surface smooth;

[0086] 2) Brush the adhesive agent on the inner and outer surfaces of the composite carbon fiber insulation cylinder 9 after the surface polishing treatment for 3 to 6 times to form the adhesive layer 10, and the adhesive agent used conventionally can be used as the adhesive agent;

[0087] 3) Put the composite carbon fiber insulation cylinder 9 coated with the adhesive layer 10 into a heating furnace, raise the temperature to 240° C. at a heating rate of 5° C. / min, keep the temperature at this temperature for 1 hour, an...

Embodiment 3

[0090] In the present embodiment, the manufacturing method of the high-performance composite carbon fiber insulation cylinder is as follows:

[0091] 1) Prepare chopped carbon fibers; chop the pitch-based carbon fibers to obtain chopped carbon fibers with an average length of 80 mm;

[0092] 2) preparing ground carbon fibers; grinding the pitch-based carbon fibers to obtain ground carbon fibers with an average length of 180 μm;

[0093] 3) Using a cyclone separator to fully mix the chopped carbon fiber and the ground carbon fiber according to the weight ratio of 50:50 to obtain the mixed carbon fiber;

[0094] 4) Mix the mixed carbon fiber with the organic binder phenolic resin and solvent ethanol in a weight ratio of 100:55:75 to obtain a carbon fiber mixture; put the carbon fiber mixture into a mesh bag, pass through a mesh with a mesh size of 30 μm After the bag is pre-filtered, hot air at 60°C is blown directly into the mesh bag for 30 minutes to completely evaporate the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com