A working method of glass product cutting water jet

A technology of glass products and working methods, which is applied in the direction of glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as unreachable, and achieve the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below by specific embodiments:

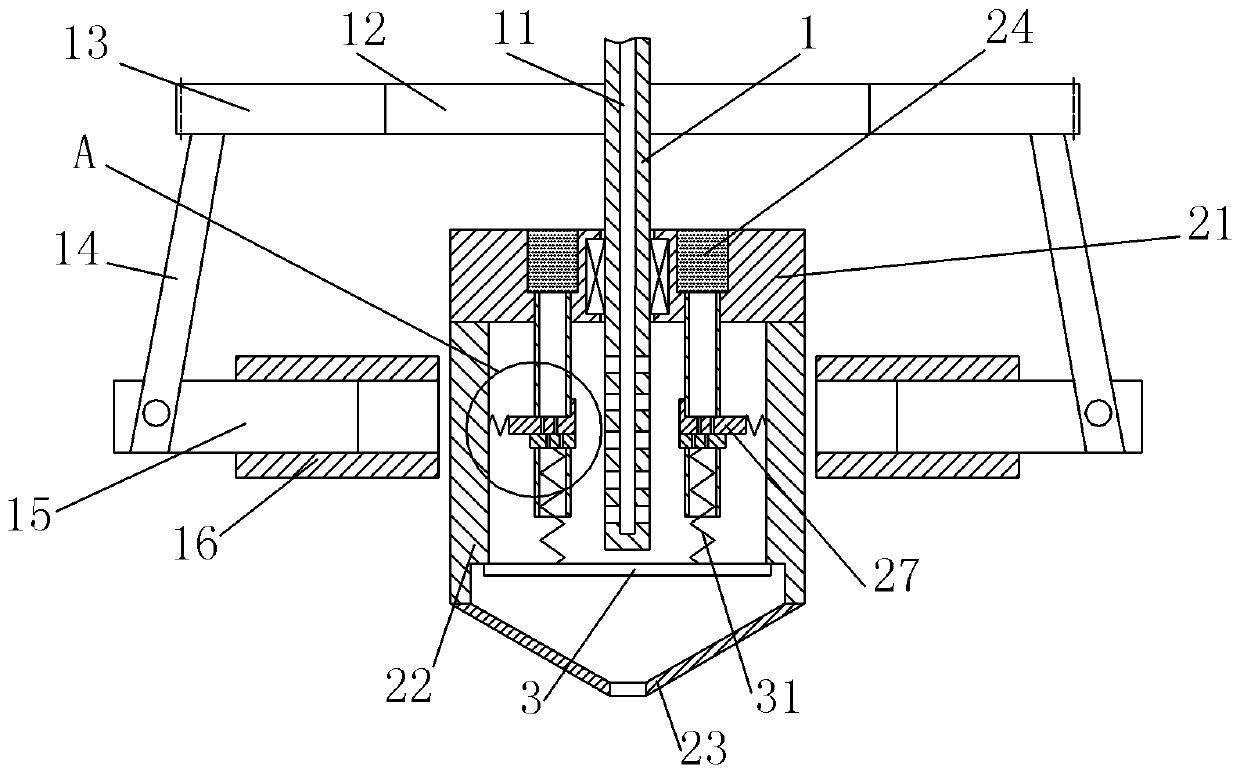

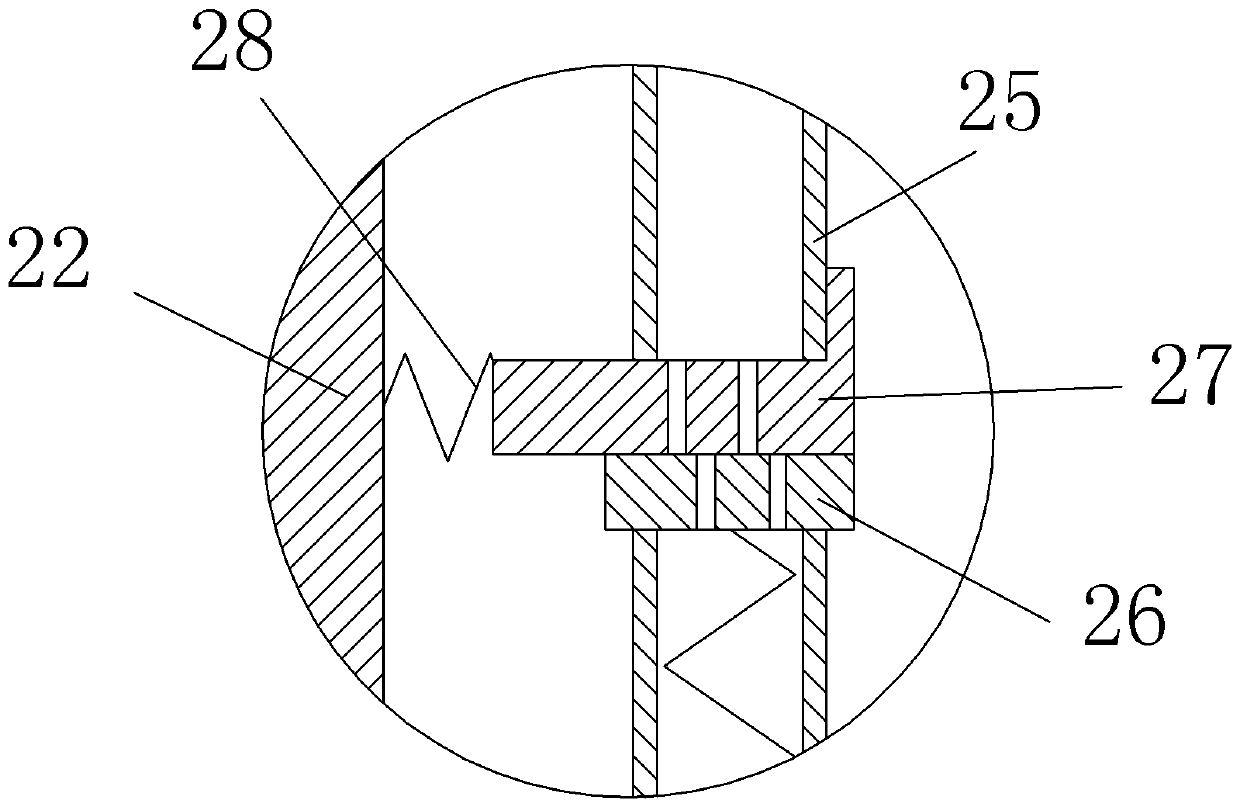

[0023] The reference signs in the drawings include: rotating shaft 1, water inlet 11, driving gear 12, driven gear 13, connecting rod 14, pressing rod 15, chute 16, mounting seat 21, elastic member 22, nozzle 23, The fine sand chamber 24 , the sand adding pipe 25 , the first filter plate 26 , the second filter plate 27 , the second spring 28 , the partition plate 3 , and the first spring 31 .

[0024] The water jet structure used in this scheme is basically as attached figure 1 and attached figure 2Shown: a glass product cutting water jet, including a nozzle, the nozzle includes a mounting seat 21, an elastic member 22 and a nozzle 23 in sequence from top to bottom, and a working chamber is formed between the mounting seat 21, the nozzle 23 and the elastic member 22. The elastic member 22 is also provided with a positioning groove, the positioning groove is provided with a baffle 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com