Effluent oil water separation device

A separation device, technology of sewage oil and water, applied in the direction of separation method, liquid separation, grease/oily substance/floating matter removal device, etc., can solve the problems of poor oil-water separation effect, poor separation effect, unfavorable filter core, etc., to achieve The effect of promoting flotation, reducing oil content and improving separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

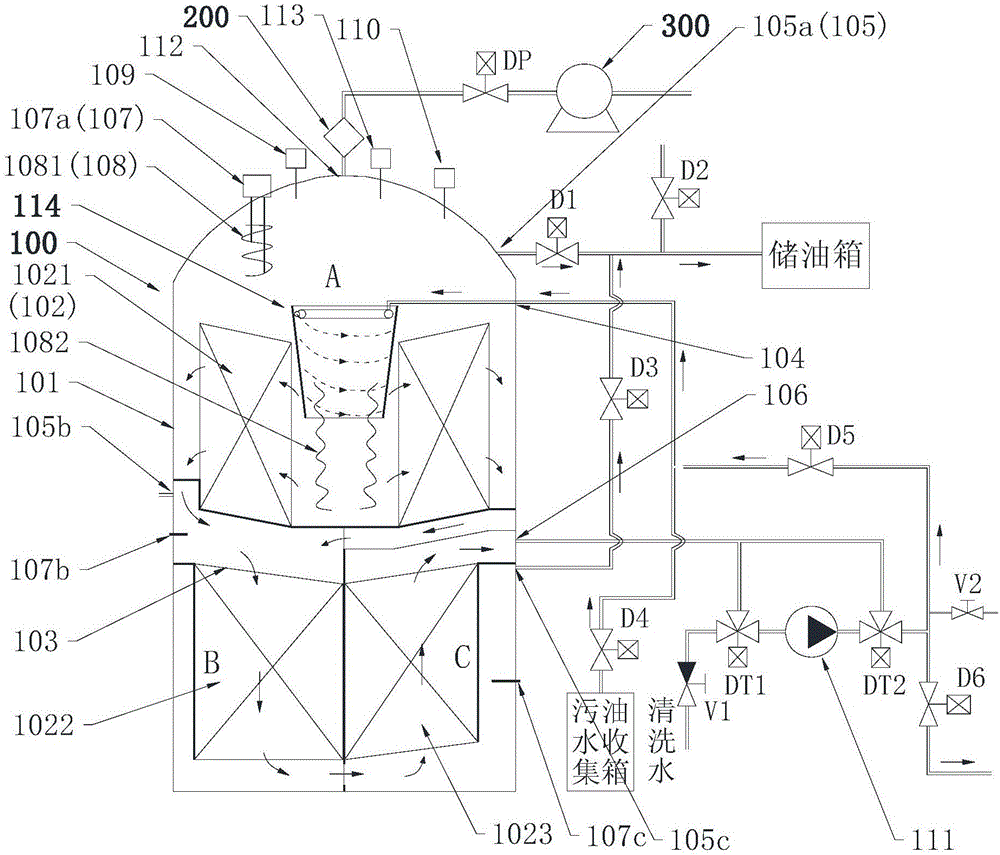

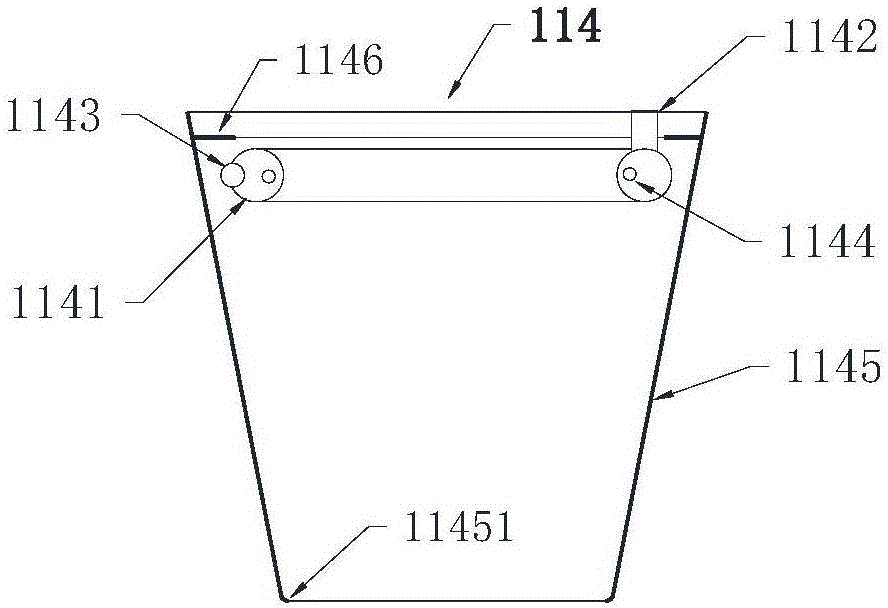

[0029] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific implementation methods.

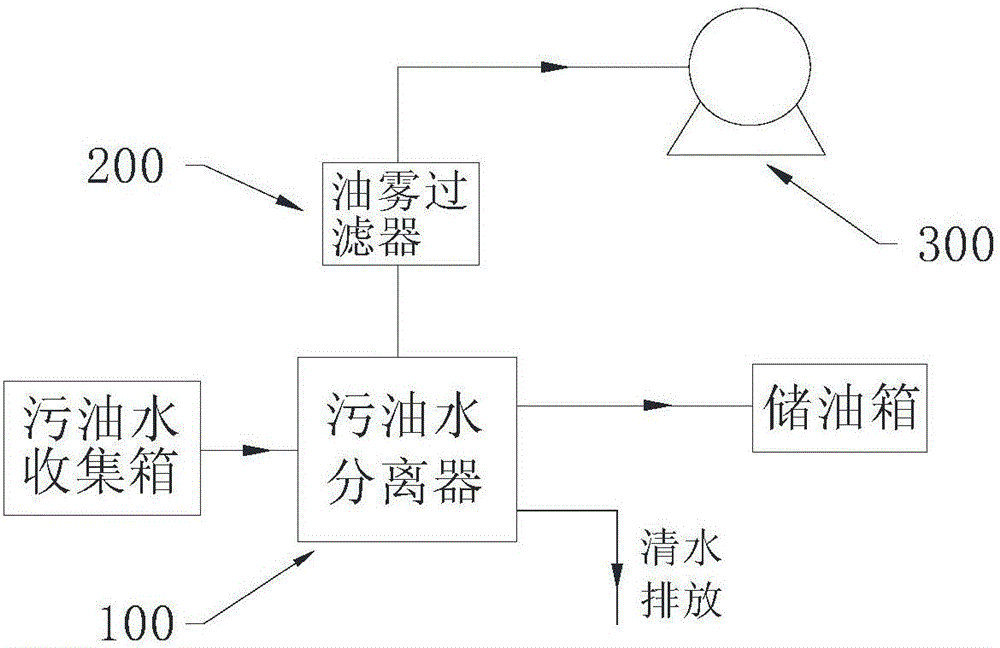

[0030] A kind of sewage oil-water separation device of the present invention, as Figure 1-Figure 2 As shown, the separation device includes a sewage oil-water separator 100, an oil mist filter 200, a vacuum pump 300, an oil storage tank, a sewage oil-water collection tank and a controller. The controller is used for automatic control of the sewage oil-water separation device. The top of the sewage oil-water separator 100 is provided with an air suction port 112 and an input port 104 for inputting waste oil and water to be treated. The output port of the dirty oil and water collection tank communicates with the input port 104, the input port of the oil mist filter 200 communicates with the suction port 112, and the input port of the vacuum pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com