Front-end filtering device of filter

A front-end filter and filter technology, which is applied in the direction of fuel air filter, charging system, machine/engine, etc., can solve the problem of uneven mixing of engine gas and oil, affecting the quality of engine air intake, and lower filter performance, etc. problems, to achieve the effect of strong comprehensive practicability, easy popularization and use, and lighten the filtering load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

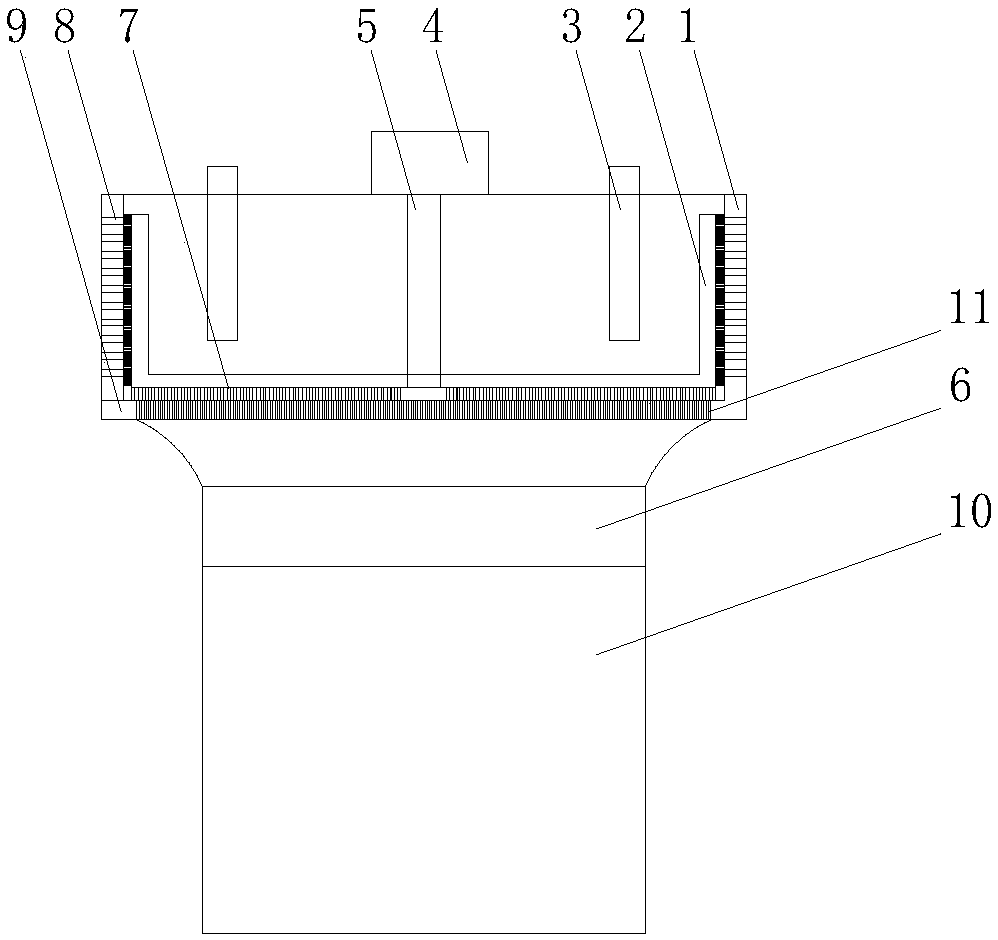

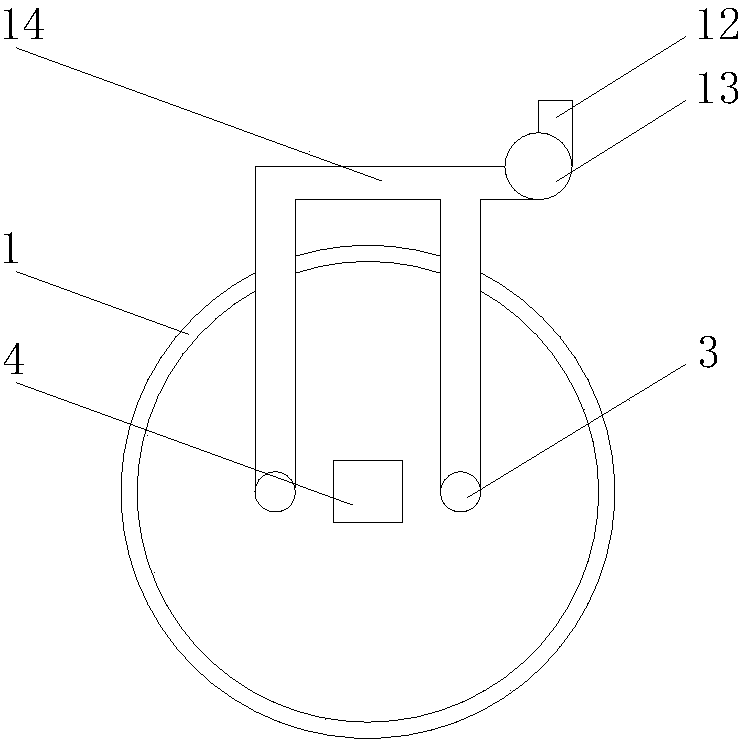

[0017] Example 1, see Figure 1-2 , a filter front-end filter device, including a filter inlet 10 and a filter cover 1, the side of the filter cover 1 is provided with a number of evenly distributed first filter holes 8, the bottom of the filter cover 1 is connected through a connecting ring 6 is connected to the air inlet 10 of the filter, the bottom of the filter cover 1 is provided with a filter plate 9, the filter plate 9 is provided with a number of evenly distributed second filter holes 11, and the middle part of the filter cover 1 is provided with a rotating shaft 5. The bottom of the rotating shaft 5 is provided with a cleaning rod 2, and the cleaning rod 2 is provided with a cleaning brush 7. The upper end of the rotating shaft 5 passes through the filter cover 1 and is connected with the motor 4. Suction rods are provided on both sides of the motor 4. Dust pipe 3, the dust suction pipe 3 is connected with the small fan 13 through the air intake main pipe 14, the othe...

Embodiment 2

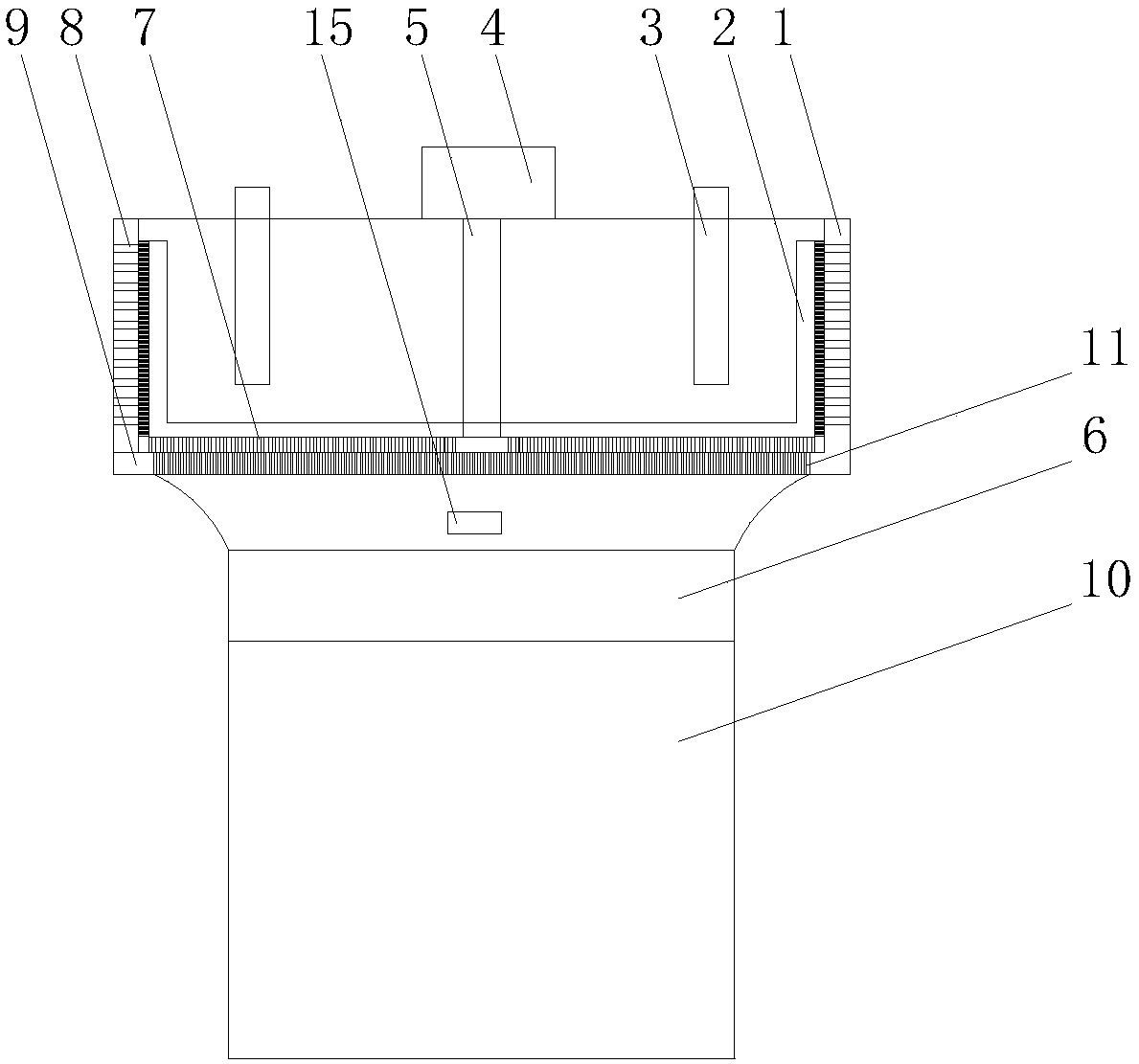

[0018] Example 2, see image 3 , a filter front-end filter device, including a filter inlet 10 and a filter cover 1, the side of the filter cover 1 is provided with a number of evenly distributed first filter holes 8, the bottom of the filter cover 1 is connected through a connecting ring 6 is connected to the air inlet 10 of the filter, the bottom of the filter cover 1 is provided with a filter plate 9, the filter plate 9 is provided with a number of evenly distributed second filter holes 11, and the middle part of the filter cover 1 is provided with a rotating shaft 5. The bottom of the rotating shaft 5 is provided with a cleaning rod 2, and the cleaning rod 2 is provided with a cleaning brush 7. The upper end of the rotating shaft 5 passes through the filter cover 1 and is connected with the motor 4. Suction rods are provided on both sides of the motor 4. Dust pipe 3, the dust suction pipe 3 is connected with the small fan 13 through the air intake main pipe 14, the other s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com