Preparation method of Mn2O3 having yolk-eggshell structure

A technology of manganese trioxide and eggshell, which is applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of manganese trioxide that have not been reported, and achieve the effect of uniform shape, good dispersion and short reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Manganese nitrate and urea are dissolved in deionized water respectively, the molar concentration of manganese ions in the solution after dissolving is 1mol / L, and the molar concentration of urea is 1mol / L, and it is standby after fully dissolving;

[0017] (2) Mix the two solutions obtained in step (1), the mixing ratio is that the molar ratio of manganese ions to urea is 1:3; condense and reflux for 60 minutes under the microwave excitation heating condition with a power of 700W, and cool to room temperature naturally Centrifugal separation obtains manganese carbonate precursor;

[0018] (3) Put the manganese carbonate precursor obtained in the previous step into a high-temperature furnace for heat treatment at 400° C. for 5 hours, and cool down to room temperature with the furnace to obtain manganese trioxide with egg yolk-eggshell structure.

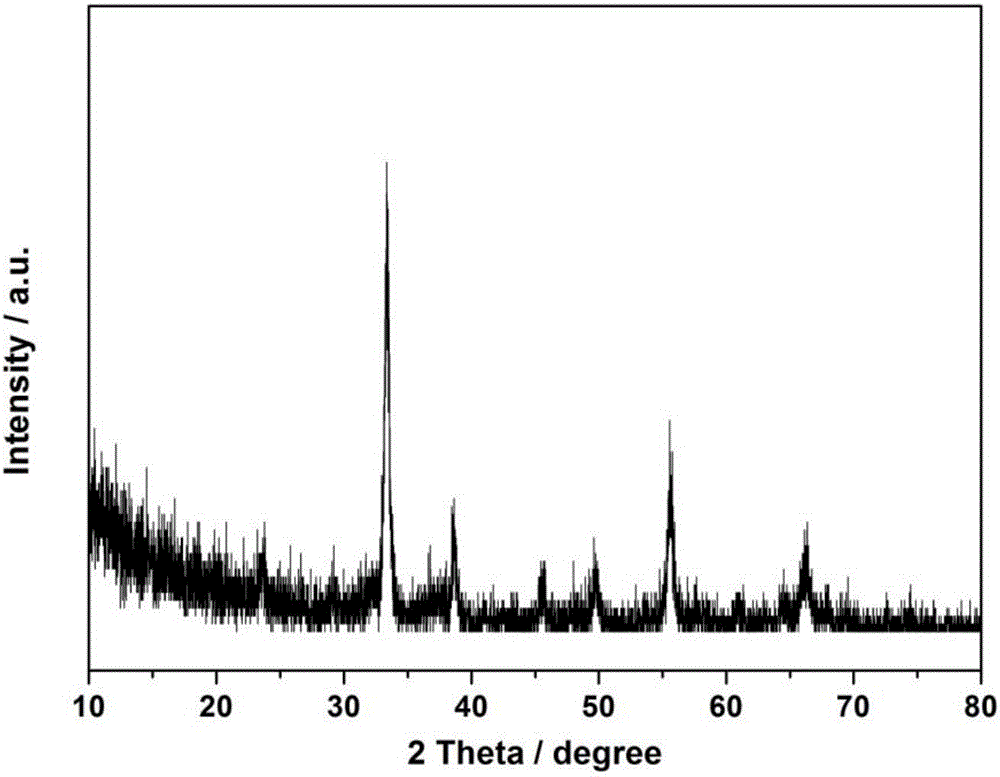

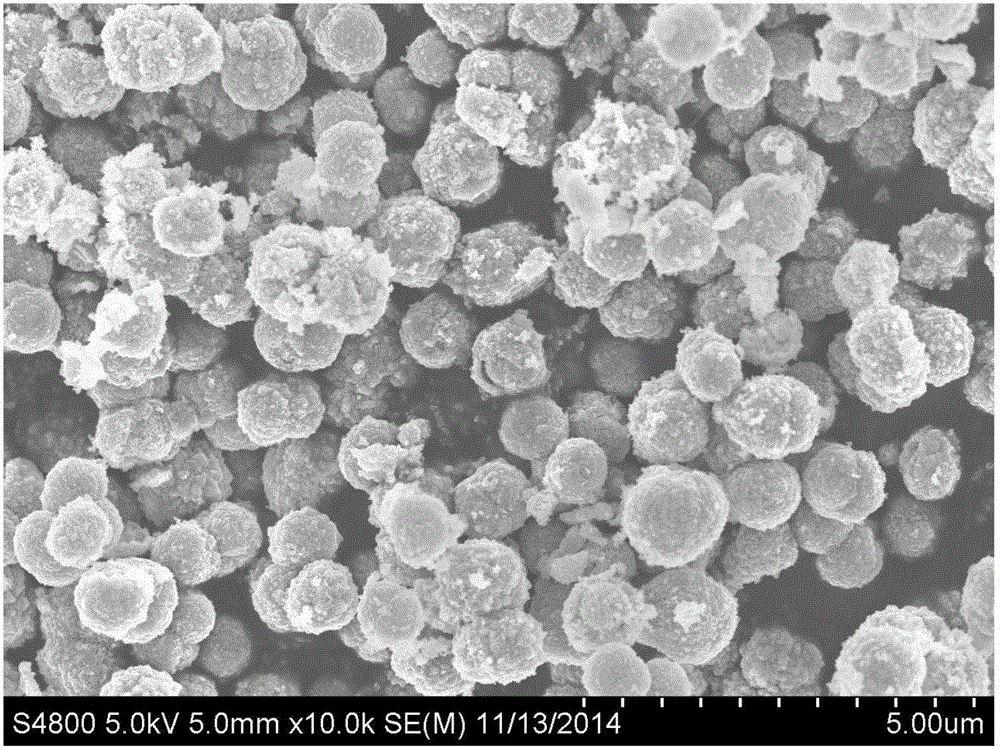

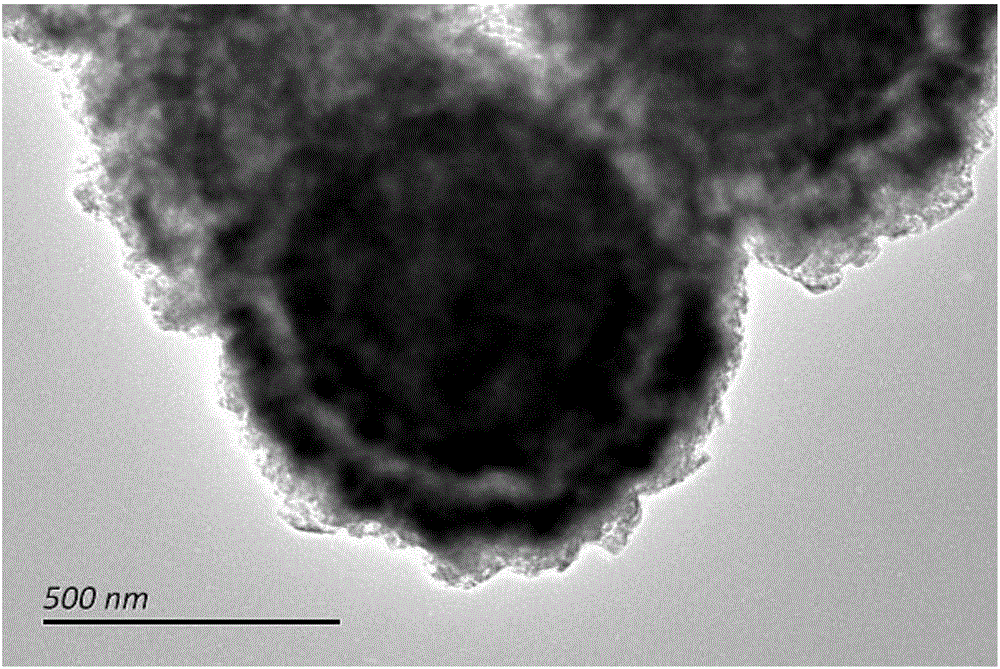

[0019] figure 1 For the X-ray diffraction pattern of the manganese trioxide with egg yolk-eggshell structure prepared i...

Embodiment 2

[0021] (1) Manganese acetate and sodium hydroxide are dissolved in deionized water and ethylene glycol respectively, and the molar concentration of manganese ion in the solution after dissolving is 0.1mol / L, and the molar concentration of sodium hydroxide is 0.5mol / L, fully ready after dissolving;

[0022] (2) two kinds of solutions that step (1) gained are mixed, and the mixing ratio is that the mol ratio of manganese ion and sodium hydroxide is 1:1; Under the microwave excitation heating condition that power is 700W, condense and reflux for 60 minutes, cool naturally to centrifugation after room temperature to obtain the manganese carbonate precursor;

[0023] (3) Put the manganese carbonate precursor obtained in the previous step into a high-temperature furnace for heat treatment at 450° C. for 6 hours, and cool down to room temperature with the furnace to obtain manganese trioxide with egg yolk-eggshell structure.

Embodiment 3

[0025] (1) manganese sulfate and sodium hydroxide are dissolved in deionized water and Virahol respectively, the molar concentration of manganese ion in the solution after dissolving is 0.2mol / L, and the molar concentration of sodium hydroxide is 0.5mol / L, fully ready after dissolving;

[0026] (2) two kinds of solutions that step (1) gained are mixed, and the mixing ratio is that the mol ratio of manganese ion and sodium hydroxide is 1:2; Under the microwave excitation heating condition that power is 700W, condense and reflux for 60 minutes, cool naturally to centrifugation after room temperature to obtain the manganese carbonate precursor;

[0027] (3) Put the manganese carbonate precursor obtained in the previous step into a high-temperature furnace for heat treatment at 500° C. for 3 hours, and cool down to room temperature with the furnace to obtain manganese trioxide with egg yolk-eggshell structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com