Device of feeding solid powder into high-speed air flow

A high-speed airflow, solid powder technology, used in conveying bulk materials, conveyors, transportation and packaging, etc., to reduce strength, extend service life, and improve uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

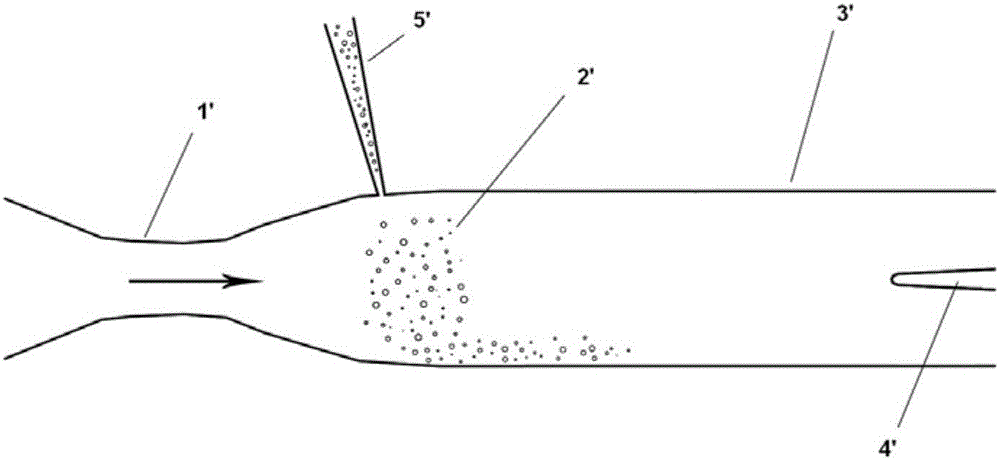

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

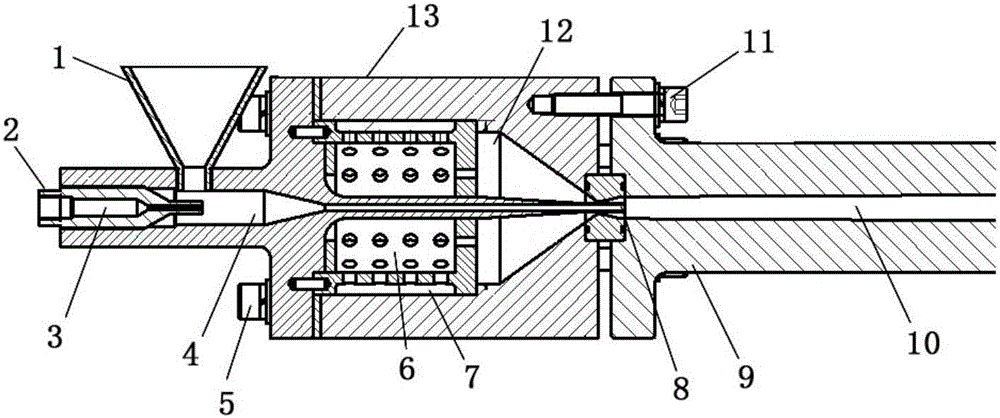

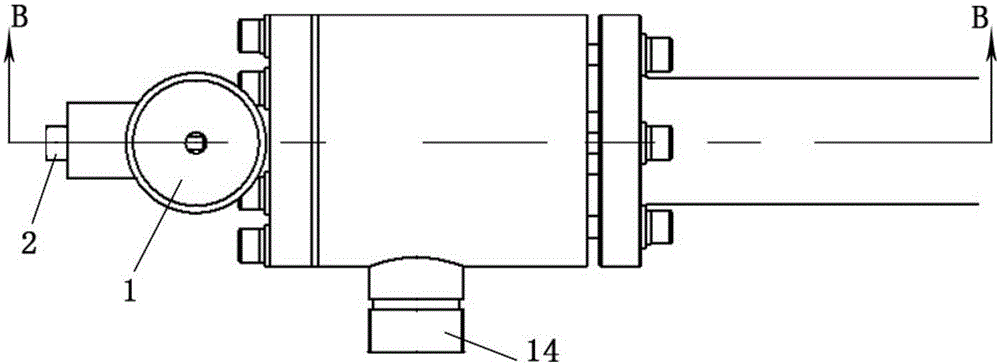

[0020] The low-temperature solid-phase reaction side air inlet axial feed device designed by the present invention has a structure such as figure 2 , image 3 shown. A device for sending solid powder into a high-speed airflow, which uses a carrier gas to send the solid powder into the high-speed airflow, and sequentially arranges a feeding pipe 4, an airflow stabilizing outer cover 13, and a high-speed airflow accelerating pipe 9 along the direction of the airflow. The feeding pipe 4 It is a three-stage structure, the front section is a feed slender tube, the middle section is a flange structure, and the rear section is a delivery pipe; the feed slender tube of the feed pipe 4 is inserted into and penetrates the inner cavity of the airflow stabilization cover 13, and is injected by a supersonic jet The pipe 8 connects the feed pipe 4 to the outlet of the elongated feed pipe, the airflow stabilization cover 13 and the high-speed airflow passage 10 of the high-speed airflow ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com