Automatic rod feeding device for cotton candy

A cotton candy, automatic technology, applied in confectionery, confectionery industry, stick distribution, etc., can solve the problems of manual stick taking is not hygienic and unclean, and achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

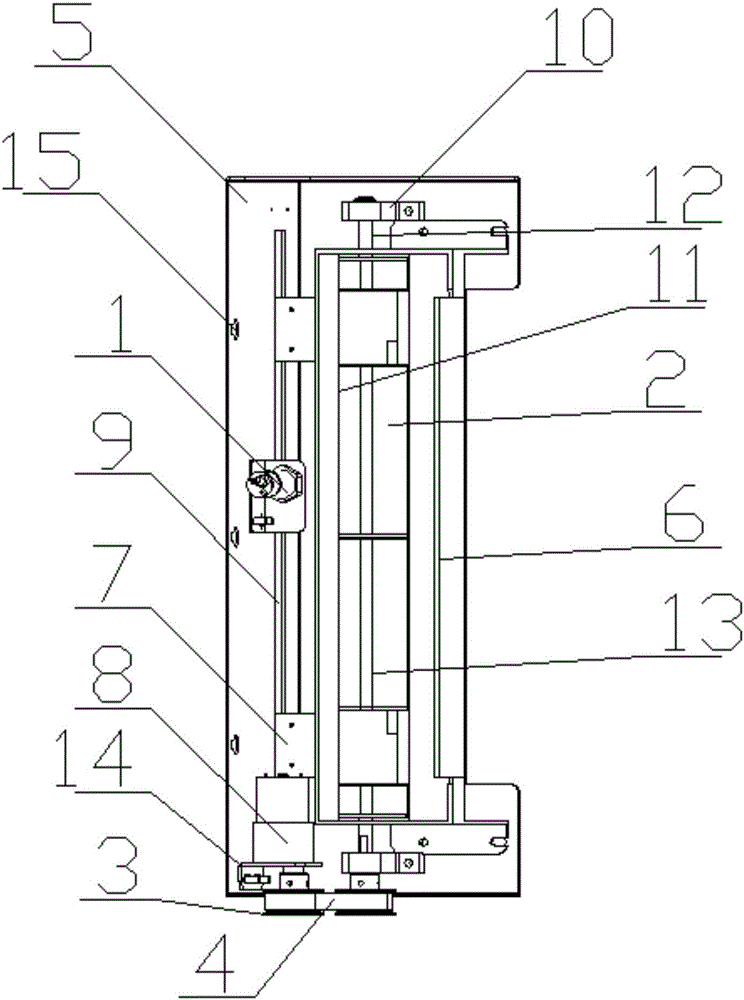

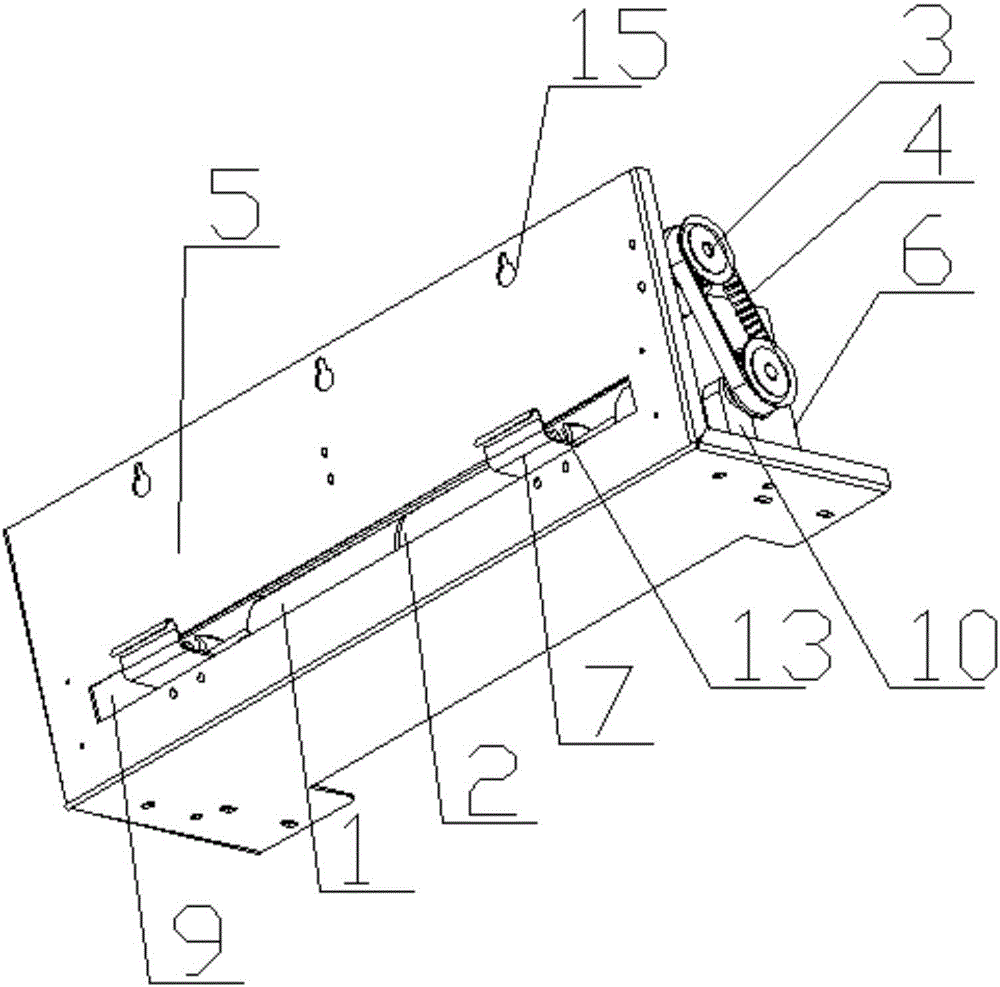

[0013] figure 1 , figure 2 and image 3 Show the specific embodiment of the present invention: a kind of marshmallow automatic rod feeder, comprise L-shaped installation and fixing frame 5, the rear end of described L-shaped installation and fixing frame 5 is provided with outlet 9, and inside described rod outlet 9 A rod-out bracket 7 is provided, and a transparent rod storage box 6 is arranged on the L-shaped mounting bracket 5. A bearing seat 10 is respectively provided at both ends of the transparent rod storage box 6. The transparent rod storage box 6 The rear wall is provided with an outlet 11, and the transparent rod storage box 6 is provided with a rod discharging cylinder 2, and the rod discharging cylinder 2 is provided with a rotating shaft 12, and the rotating shaft 12 is arranged in the bearing seat 10, and the The front and rear walls of the transparent rod storage box 6 fit together with the rod discharge cylinder 2, and the rod discharge cylinder 2 is evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com