Automatic packaging equipment for protective glasses

An automatic packaging and protective glasses technology, which is applied in packaging, transport packaging, transportation and packaging, etc., can solve the problems of time-consuming, manpower-consuming, light and thin glasses packaging bags, and small size margin, etc., and achieve high efficiency and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

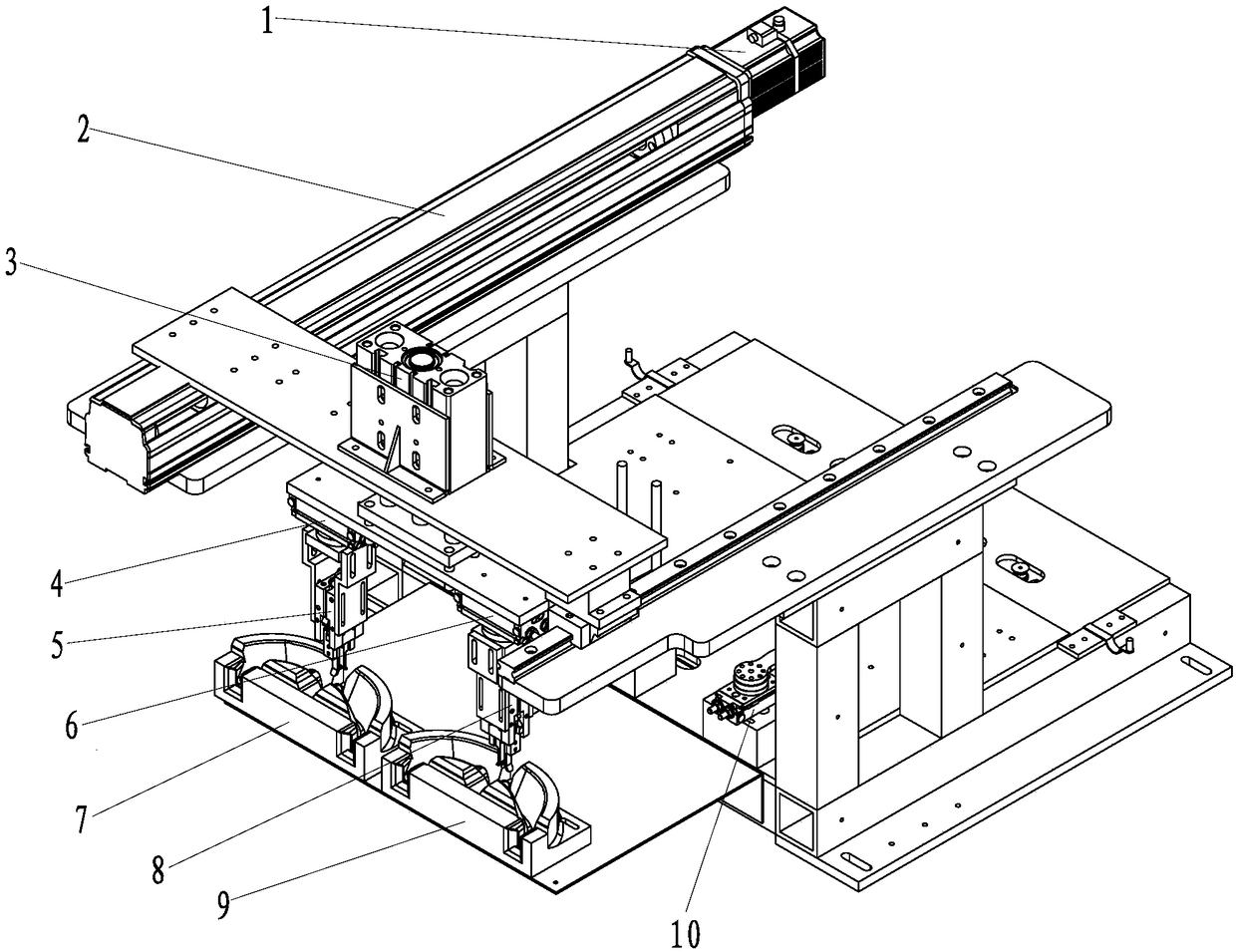

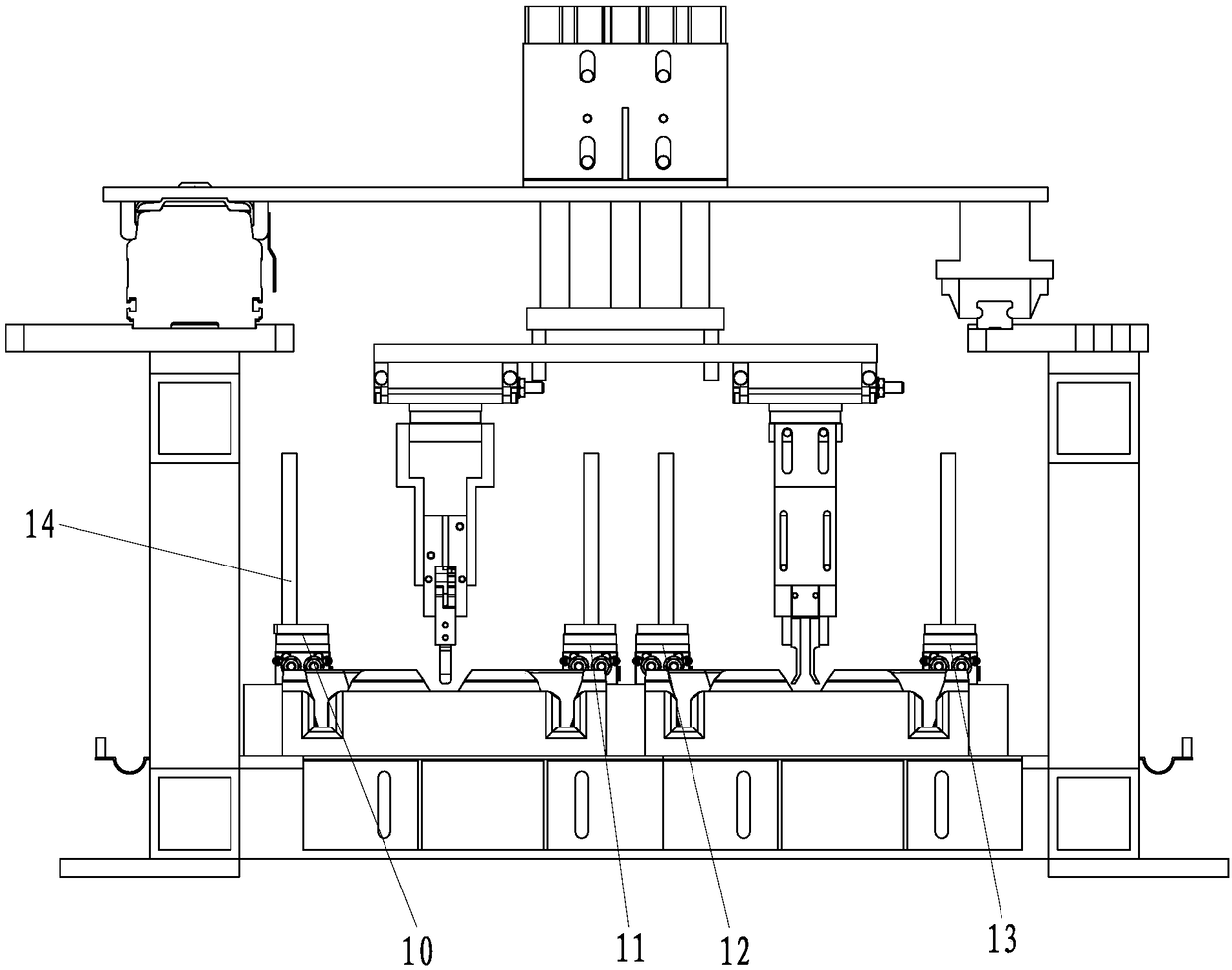

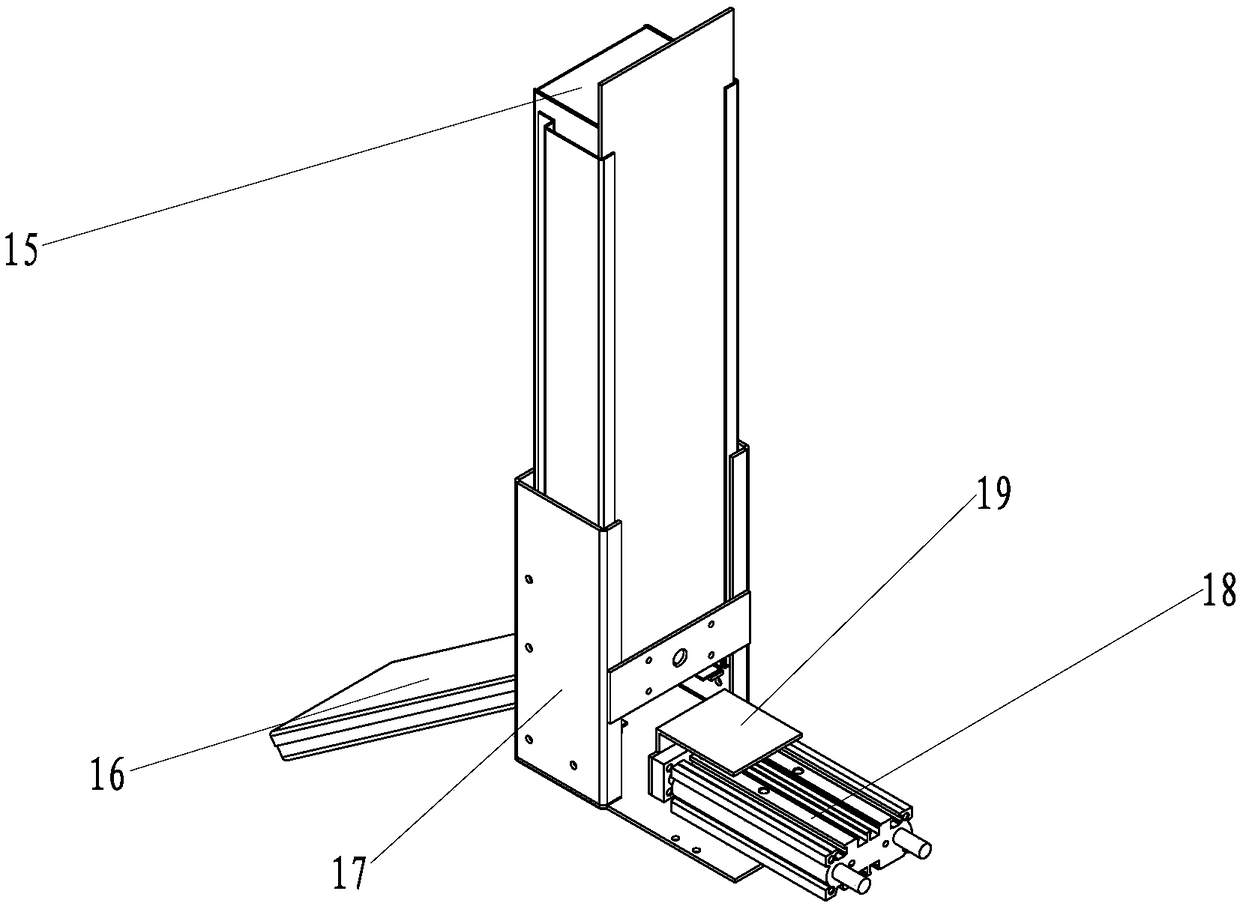

[0030] see Figure 1 to Figure 5 , the front end of the mechanism is the fixtures 7 and 9 for placing glasses. When glasses are placed in the fixture, the pressure sensor in the fixture senses that the glasses are put in, the first lifting cylinder 3 descends, and the first pneumatic finger 5 , 8 is closed, the middle position of the glasses is clamped, after the glasses are clamped, the first lifting cylinder 3 rises, the first motor 1 drives the first screw module 2 to move, and reaches the top of the rotating cylinders 10, 11, 12, 13, The 4 rotating cylinders drive the 4 rotating rods 14 to rotate in sequence, and push the temples to the mirror surface to complete the folding of the temples. After the temples are folded, the total rotation cylinders 4 and 6 rotate, driving the glasses to rotate 90 degrees, and at the same time, the first motor 1 continues to drive the first screw module 2 to move to the bagging position, and reaches the bagging grooves 30 and 40 of the bagg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com