Molten pool monitoring device for laser processing process

A laser processing and monitoring device technology, which is applied in the direction of optical testing for flaws/defects, can solve problems such as low processing quality and prone to defects, and achieve the effect of avoiding mutual occlusion, false detection and harm to monitoring personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

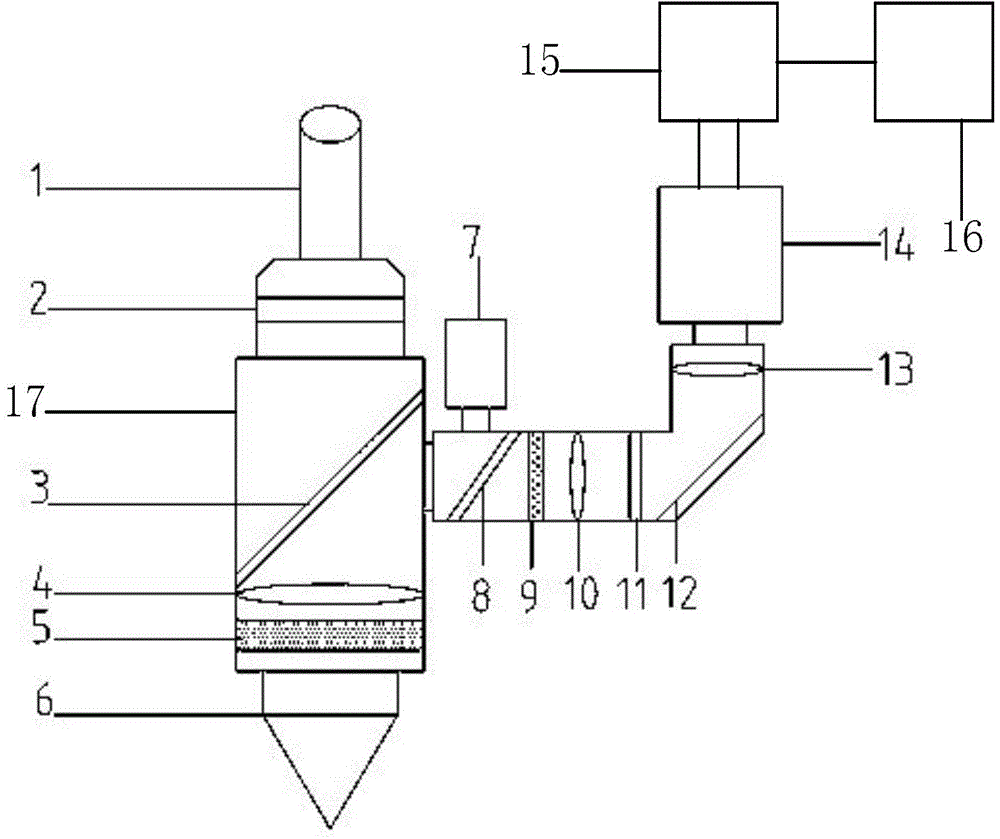

[0028] like figure 2 As shown, the embodiment of the present invention provides a molten pool monitoring device used in the laser processing process. In the laser processing process, the laser beam 1 passes through the collimating mirror 2, the focusing mirror 4, and the protective mirror in the laser head 17 in sequence. 5 and the nozzle 6 reach the surface of the substrate 19 or the cladding layer 20 to form a molten pool 18 on the surface of the substrate 19 or the cladding layer 20, and the molten pool monitoring device includes a beam splitter 3, a lens module and an acquisition control system, The beam splitter 3 is arranged between the collimating mirror 2 and the focusing mirror 4 in the laser head 17, and is fixedly arranged at an angle of 45° with the laser beam 2, and the beam splitter 3 makes the laser beam 1 It is located on the same axis as the visible light reflected from the melting pool 18, and its incident angle differs by 180°. The visible light is focused ...

Embodiment 2

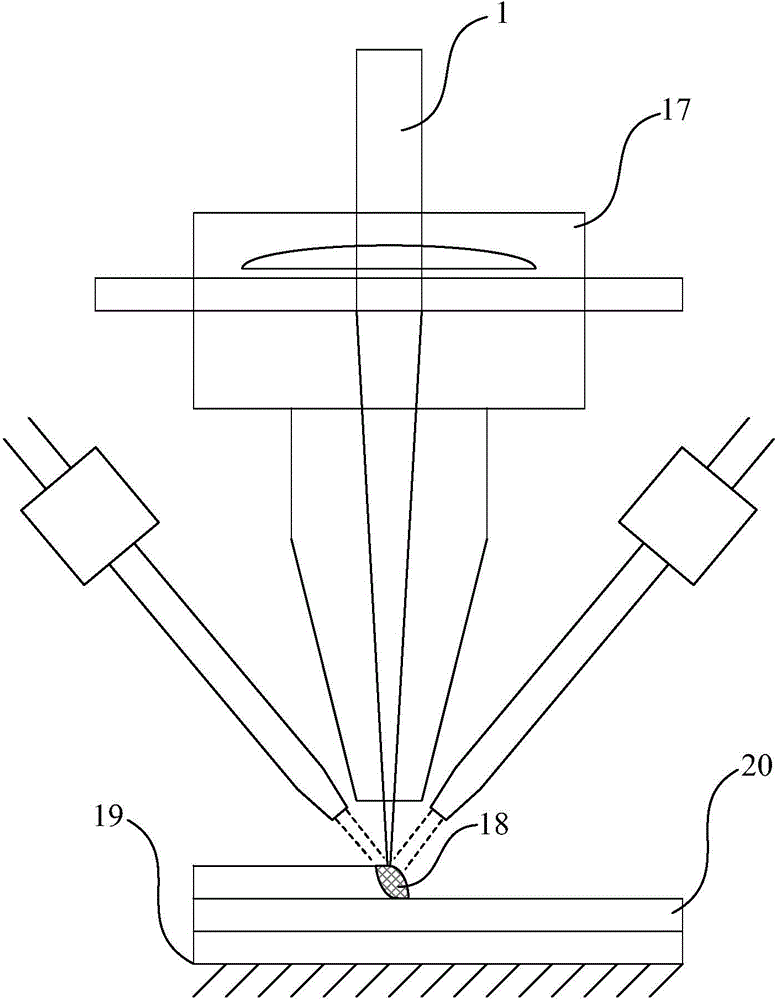

[0036] like image 3 As shown, compared with Embodiment 1, the technical features of the embodiment of the present invention are basically the same, and the only difference is that the laser beam 7 enters the laser head 17 from one side of the laser head 17, and the lens The module is located above the laser head 17, the beam splitter 3 reflects the laser beam 1 to make it reach the surface of the substrate 19 or the cladding layer 20, and transmits the visible light reflected from the molten pool 18 to make it into the lens module.

[0037] Combining Embodiment 1 and Embodiment 2, it can be concluded that the molten pool monitoring device provided by the present invention is applicable to laser heads 17 with different structures, which shows that the molten pool monitoring device has strong adaptability.

[0038] To sum up, the melt pool monitoring device for laser processing provided by the embodiment of the present invention makes the imaging optical path and the laser opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com