A kind of preparation method of ceramic electrician blade

A blade and electrical technology, applied in the field of preparation of ceramic electrical blades, can solve the problems of easy chipping, missing corners or fractures, and low toughness, and achieve good wear resistance, improved toughness, and high wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

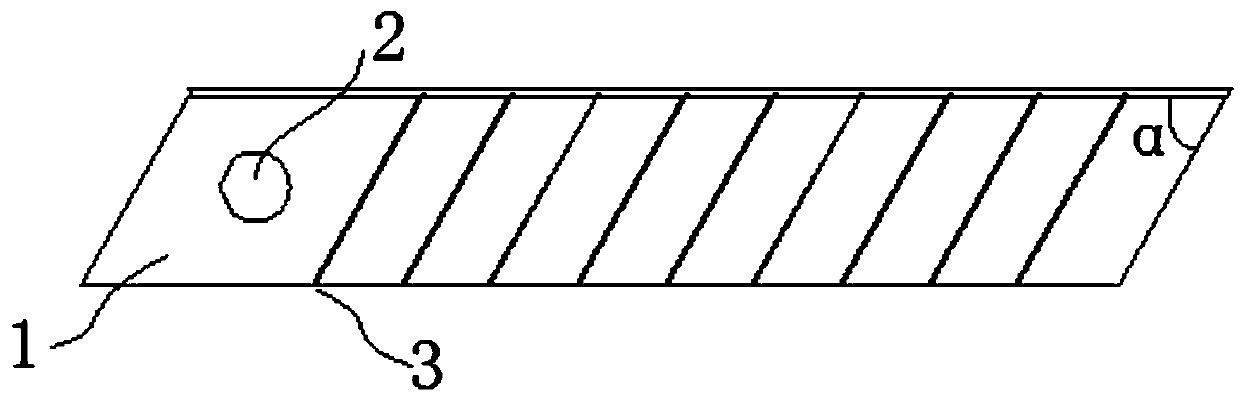

[0037] like figure 1 As shown, a ceramic electrician blade comprises a blade body 1 and a mounting hole 2, the blade body 1 is a parallelogram, and the acute angle α of the quadrilateral is 30° (that is, the angle between the front edge of the blade body 1 and the straight line where the edge of the blade is located), and the length of the blade body is 105mm , with a width of 18mm and a thickness of 0.5±0.03mm; the installation hole 2 is located at one end of the knife body 1, and the diameter of the installation hole 2 is 5.5mm; one side of the knife body 1 is provided with at least one breaking groove 3, and the cross section of the breaking groove 3 is V-shaped, the breaking groove 3 is parallel to the leading edge of the blade. When the tip of the blade is blunted or chipped, the blade can be broken along one of the breaking grooves to regenerate a new blade tip.

[0038] The processing method of the ceramic electrical blade in the present embodiment is:

[0039](1) Cera...

Embodiment 2

[0049] like figure 1 As shown, a ceramic electrician blade comprises a blade body 1 and a mounting hole 2, the blade body 1 is a parallelogram, and the acute angle α of the quadrilateral is 28° (that is, the angle between the front edge of the blade body 1 and the straight line where the edge of the blade is located), and the length of the blade body is 105mm , with a width of 12mm and a thickness of 0.5±0.03mm; the installation hole 2 is located at one end of the blade body 1, and the diameter of the installation hole 2 is 5.5mm; one side of the blade body 1 is provided with a breaking groove 3, and the cross section of the breaking groove 3 is V-shaped .

[0050] The processing method of the ceramic electrical blade in the present embodiment is:

[0051] (1) Ceramic blank sintering: pass zirconia powder and alumina powder through a 200-mesh sieve respectively, then mix and grind zirconia powder, alumina powder and binder in a mass ratio of 10:2.5:0.5, and use high temperatu...

Embodiment 3

[0060] A ceramic electrical blade, comprising a blade body 1 and a mounting hole 2, the blade body 1 is a parallelogram, the acute angle α of the quadrilateral is 40° (that is, the angle between the front edge of the blade body 1 and the straight line where the blade edge is located), the length of the blade body is 105mm, and the width is 18mm, the thickness is 0.6±0.03mm; the installation hole 2 is located at one end of the blade body 1, and the diameter of the installation hole 2 is 5.5mm; one side of the blade body 1 is provided with a breaking groove 3, and the cross section of the breaking groove 3 is V-shaped.

[0061] The processing method of the ceramic electrical blade in the present embodiment is:

[0062] (1) Ceramic blank sintering: Pass zirconia powder and alumina powder through a 200-mesh sieve respectively, then mix and grind zirconia powder, alumina powder and binder in a mass ratio of 10:2.15:0.5, and use high temperature It is sintered by isostatic pressing,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com