An octagonal circular blade for cutting soft materials containing hard impurities and its manufacturing method

A technology of soft materials and manufacturing methods, applied in other manufacturing equipment/tools, manufacturing tools, metal processing, etc., can solve problems such as easy cracking of the knife edge, achieve the effects of reducing resistance, reducing wear and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

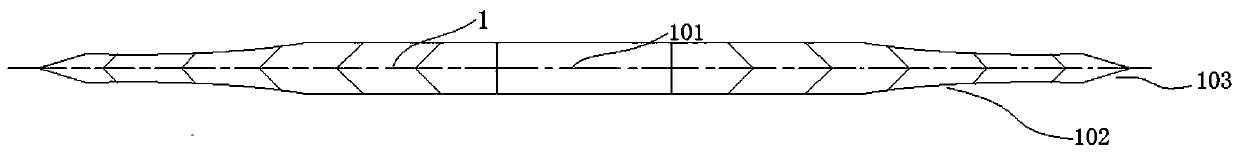

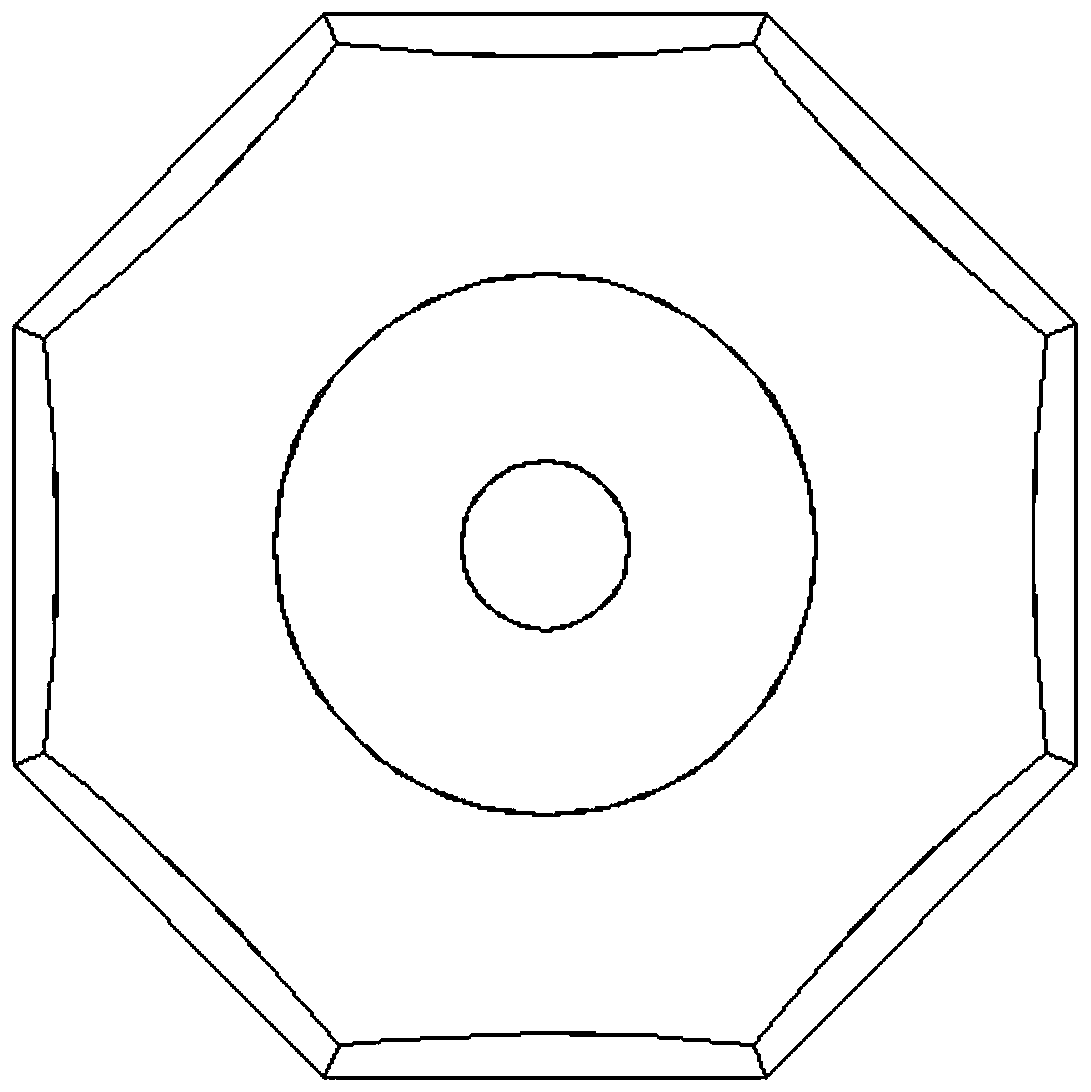

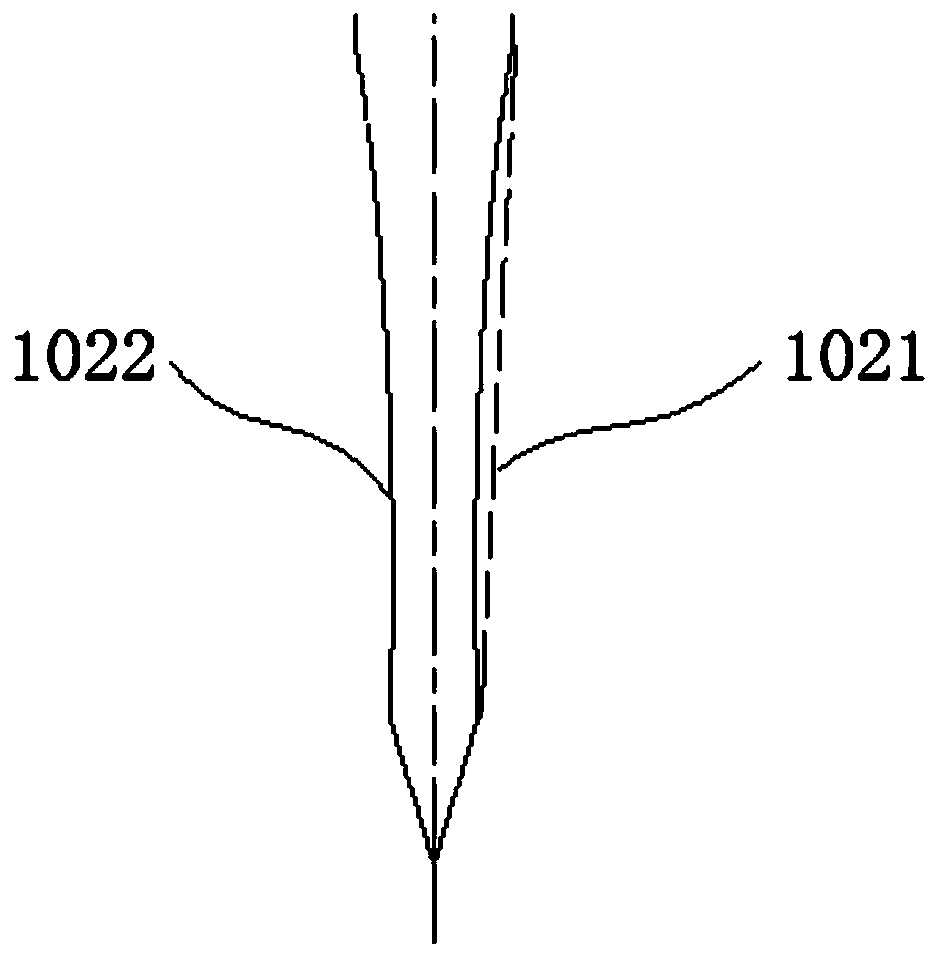

[0037] Such as Figure 1 ~ Figure 3 As shown, an octagonal round blade for cutting soft materials containing hard impurities includes a regular octagonal blade body 1, the center of the blade body 1 is provided with a mounting hole 101, and each edge of the octagon is provided with a large knife edge 102 and a small knife edge 103, the section line 1022 of the large knife edge 102 along the diameter direction of the circular blade is arc-shaped; the central angle corresponding to the section line 1022 is 12°, and the length of the section line 1022 is 0.35 times the diameter of the circular blade. The sectional view of the large edge of the existing common disc cutter is as follows: image 3 As shown in 1021, it is in the shape of an inclined plane. The cutting edge of this shape has a large resistance during cutting and is easily worn by impurities.

[0038]The applicant has been engaged in the production of blades for a long time, and has continuously obtained a series of h...

Embodiment 2

[0049] Such as Figure 1 ~ Figure 3 As shown, an octagonal circular blade for cutting soft materials containing hard impurities includes a regular octagonal blade body 1, the center of the blade body 1 is provided with a mounting hole 101, and each side edge of the octagon is provided with a large knife edge 102 and a small knife edge 103, the section line 1022 of the large knife edge 102 along the diameter direction of the circular blade is arc-shaped; the central angle corresponding to the section line 1022 is 10°, and the length of the section line 1022 is 0.4 times the diameter of the circular blade. The sectional view of the large edge of the existing common disc cutter is as follows: image 3 As shown in 1021, it is in the shape of an inclined plane. The cutting edge of this shape has a large resistance during cutting and is easily worn by impurities.

[0050] The applicant has been engaged in the production of blades for a long time, and has continuously obtained a ser...

Embodiment 3

[0060] Such as Figure 1 ~ Figure 3 As shown, an octagonal circular blade for cutting soft materials containing hard impurities includes a regular octagonal blade body 1, the center of the blade body 1 is provided with a mounting hole 101, and each side edge of the octagon is provided with a large knife edge 102 and a small knife edge 103, the section line 1022 of the large knife edge 102 along the diameter direction of the circular blade is arc-shaped; the central angle corresponding to the section line 1022 is 11°, and the length of the section line 1022 is 0.38 times the diameter of the circular blade. The sectional view of the large edge of the existing common disc cutter is as follows: image 3 As shown in 1021, it is in the shape of an inclined plane. The cutting edge of this shape has a large resistance during cutting and is easily worn by impurities.

[0061] The applicant has been engaged in the production of blades for a long time, and has continuously obtained a se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com