Welding tool capable of ascending, descending and being overturned

A welding tooling and lifting device technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems affecting the assembly work, low work efficiency, high labor intensity, etc., and achieve rapid displacement and good working conditions. Improve and reduce the effect of physical labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

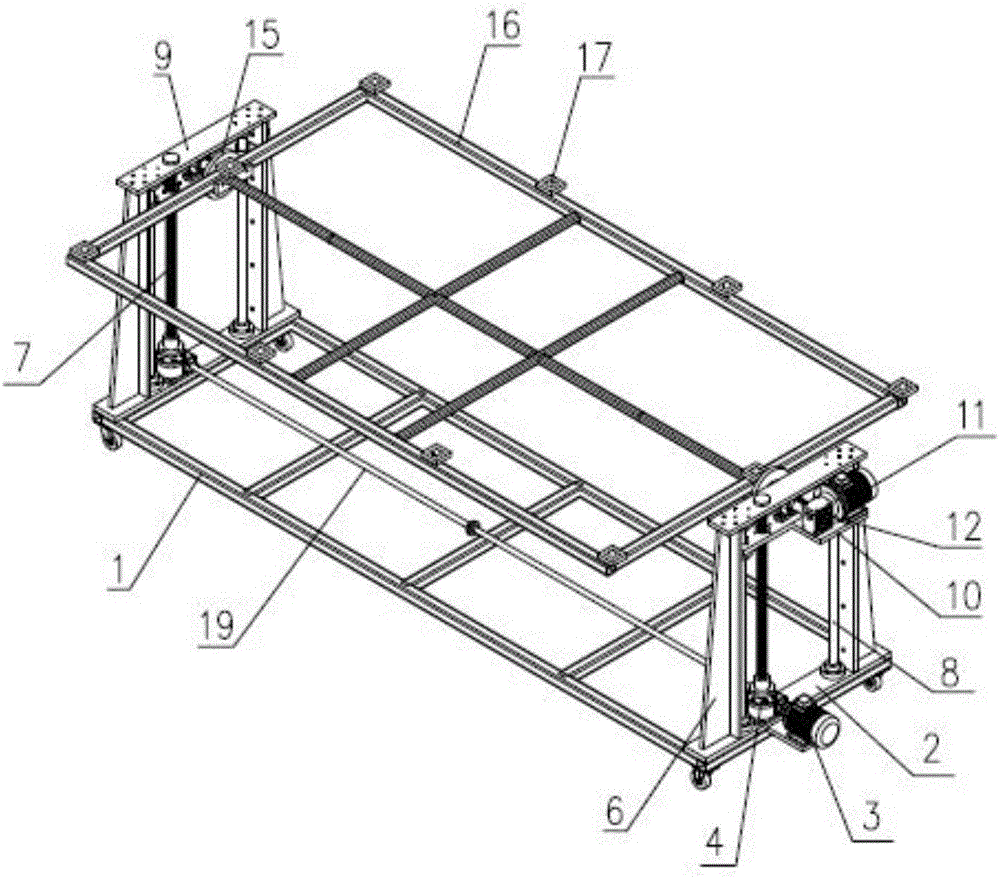

[0024] Such as Figure 1-2 As shown, a welding tool that can be lifted and turned over includes a base 1, a support frame, a lifting device for lifting the welding support 16, a rotating device for rotating the welding support 16, and the welding support 16. The support frame is arranged on the base 1. At both ends, the lifting device is arranged at the bottom of the supporting frame, the rotating device is arranged at the top of the supporting frame, and the welding bracket 16 is arranged on the rotating device.

[0025] The support frame includes a base plate 2, a side reinforcement plate 5, a vertical plate 6 and a top plate 9, the base plate 2 is respectively installed at both ends of the base 1, the vertical plate 6 is vertically arranged on the base 1, and the side reinforcement plate 5 is arranged on the base plate 2 And on the vertical plate 6, the top plate 9 is arranged on the top of the vertical plate 6 and the side reinforcement plate 5.

[0026] The lifting devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com